CZECH REPUBLIC: Rarely is reliable uptime so critical, as during continuous casting at a steelworks. To ensure reliable 24/7 operation of continuous casting, system integrator Ingeteam chose VACON® NXP drives to regulate the electromagnetic stirring (EMS) process at the renowned Třinecké železárny a.s., the largest steelworks in the Czech Republic.

The Třinecké železárny steelworks has relied upon VACON® drives to regulate pumps, conveyors and hoists for many years. The plant operators have built up long experience and appreciate the good programmability and ease of maintenance of these drives. They are well-suited to the harsh environment in this heavy industry, and have

demonstrated robust performance and long lifetime, many times over.

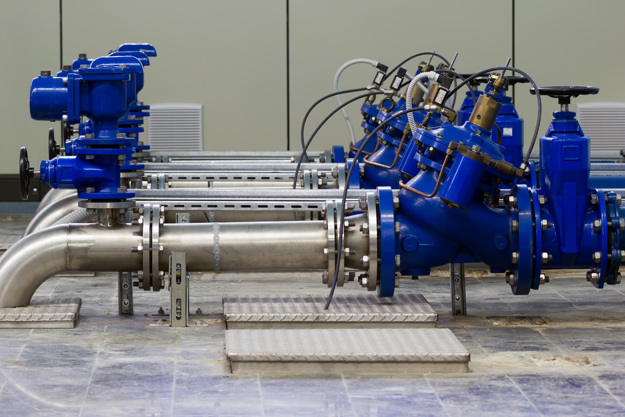

In 2018 the steelworks renovated its electromagnetic stirring (EMS) process in the continuous casting plant. In this retrofit project, VACON® NXP Standalone Drives were installed to replace a series of twenty-year-old drives from New Zealand.

The electromagenetic stirring process (EMS) involves a rotating magnetic field in huge coils. Liquid steel passes

through the coil, which acts like a stator to give the liquid steel a rotational movement. This process ensures better quality of the casted product.

With the retrofit, nine VACON® NXP Standalone Drives equipped with PROFIBUS communication were installed to control the rotating magnetic field, to maintain a frequency range of 3-5 Hz and nominal 300 A current.

Dedicated EMS control solution for the metal industry

The electromagenetic stirring process (EMS) involves a rotating magnetic field in huge coils. Liquid steel passes

through the coil, which acts like a stator to give the liquid steel a rotational movement. This process ensures better quality of the casted product.

With the retrofit, nine VACON® NXP Standalone Drives equipped with PROFIBUS communication were installed to control the rotating magnetic field, to maintain a frequency range of 3-5 Hz and nominal 300 A current. This dedicated solution has been developed specifically for optimal control of the EMS application.

100% reliability, easy serviceability and local presence

“We chose Ingeteam with Danfoss VACON® drives because they offered us the most robust solution, with 100% reliable 24/7 performance. Serviceability of the standalone drives is easy, which is vital for our steelworks in scheduled maintenance situations.

Best of all, Danfoss Drives offers us the presence of a local service and application team who participated actively throughout the planning, installation and commissioning, and who can support us with the regular service to keep the EMS process performing optimally.”

– Michal Podermanski, Project Manager, Třinecké železárny a.s.

Třinecké železárny a.s.

Established in 1839, Třinecké železárny

a.s. is the largest steel producer in the Czech Republic, exporting to more than 60 countries globally. Since its establishment, Třinecké železárny has produced approximately 180 million tons of steel. The steelworks is an important element of the region and the town of Třinec, which has changed from a small agricultural village to a considerable town, especially thanks

to Třinecké železárny. Known locally as Werk, the company supports the Czech Extra-league Ice-hockey team HC Oceláři Třinec and numerous other cultural, sport, and educational actitivities.

Learn about the drives

-

if (isSmallPicture) {

VACON® NXP Air Cooled

VACON® NXP Air CooledDesigned for a broad range of demanding applications, focusing on higher power sizes and system drives.

Read more about drives for industrial applications

-

if (isSmallPicture) {

Drives for industrial compressors

Drives for industrial compressorsAchieve significantly lower energy consumption and lower operating costs, using Danfoss AC drives to continually adjust the compressor capacity to the actual heat load and process needs.

-

if (isSmallPicture) {

Drives for industrial crane and hoist movement

Drives for industrial crane and hoist movementTo optimize crane performance, Danfoss offers flexible control strategies combined with energy efficiency, operating within stringent safety requirements.

-

if (isSmallPicture) {

Drives for industrial fans

Drives for industrial fansWith Danfoss AC drives solutions for industrial ventilation you enjoy the benefits of high precision, user-friendly interfaces, distributed intelligence and low operating costs.

-

if (isSmallPicture) {

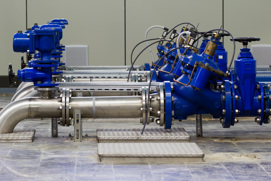

Drives for industrial pumps

Drives for industrial pumpsBy controlling industrial pumps with a Danfoss AC drive you can help optimize processes and significantly reduce energy and maintenance costs.

-

if (isSmallPicture) {

Drives for winding and unwinding in industry

Drives for winding and unwinding in industryFor lower energy consumption, increased performance, smooth ramping, and high reliability, use variable speed control for winders and unwinders.

-

if (isSmallPicture) {

Industrial DC backup ensures no more voltage dips

Industrial DC backup ensures no more voltage dipsAchieve maximum uptime even during grid disturbances. Flexible targeted battery-based industrial DC backup solutions direct power supply to the most critical loads.

These solutions support a combination of different energy storages to ensure a stable power supply when the national grid is unreliable, and ensure continuous running or controlled ramp down when required.

Read more about solutions for the metals industry

Coming soon...

Coming soon...