Ringsted District Heating Company (DHC)—a large district heating utility in Denmark—has reduced its reliance on fossil fuels by 97% after Unicool installed an innovative heat recovery system using Geoclima heat pumps built with Danfoss Turbocor® oil-free compressor technology.

With increasingly strict environmental regulations and growing costs, district heat plants are moving away from fossil fuels and turning to renewable energy—and innovative technology such as electric heat pumps and heat recovery—to reduce their environmental impact and maintain affordable heating.

Related products

-

if (isSmallPicture) {

SCA-X 15-125 check and stop valve

SCA-X 15-125 check and stop valveSCA-X are check and stop valves with built-in stop valve function. SCA-X valves are available in angleway versions.

-

if (isSmallPicture) {

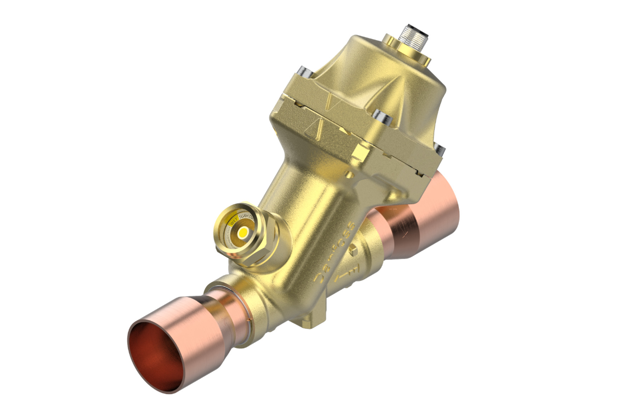

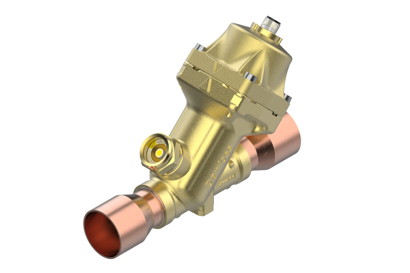

ETS 175L - ETS 500L

ETS 175L - ETS 500LA range of large electric expansion valves designed to stand a higher minimum operating pressure drop, available with S-curve and linear flow, and featuring advanced serviceability characteristics.

-

if (isSmallPicture) {

Turbocor®

Turbocor®Danfoss is the leading manufacturer of oil-free compressors and is the pioneer of the Danfoss Turbocor® compressor - the world’s first oil-free magnetic bearing compressor for the HVAC industry.

-

if (isSmallPicture) {

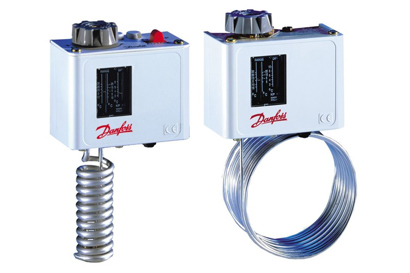

KP / KPU pressure switches, standard applications

KP / KPU pressure switches, standard applicationsKP pressure switches are optimized for light and heavy commercial refrigeration - excellent protection against low suction pressure or high discharge pressure.

-

if (isSmallPicture) {

JIP® on/off ball valves for district energy applications

JIP® on/off ball valves for district energy applicationsDanfoss JIP® Ball valves for on/off control in district heating and cooling systems. Reliable and high-quality for a long lifetime and lower TCO. Unique flow design ensures low-pressure drops and savings on pump energy.