The software with vision

Stadtwerke Altensteig (Baden-Wuerttemberg) is one of the first district heating network operators to use the brand new Leanheat® Monitor software from Danfoss. The software was specially developed to clearly display the overall heat consumption in the network, to remotely control and document all control parameters, and to use these data to optimize the efficiency and profitability of the entire system. The key here is that all return temperatures are monitored, which contributes significantly to network stability. Leanheat® Monitor offers operators a complete package for the operation of their district heating network.

Small, but active: this sums up Stadtwerke Altensteig. The energy company of this city, located in the northern Black Forest region of Baden-Wuerttemberg (Germany) and with around 11,000 inhabitants, operates distribution networks for electrical energy, gas, water, telecommunications (via fibre optics) and district heating, among other services. The company has been striving to reduce energy costs in a sustainable way since 1986: it was in this year that the first combined heat and power unit was built in a school. This CHP unit also supplied heat to a second school a few hundred metres away. This relatively small start laid the foundation for today’s extensive heat distribution network. Stadtwerke Altensteig currently operates three combined heat and power units, each with an output of 350 kW. In addition, the company uses an absorber system installed in 2017 on the roof of the sports hall of a school which extracts heat from the environment via a heat pump and feeds it into the district heating network. This works at temperatures as low as 5° C. “Combining CHP units with a heat pump has created a very economical and above all environmentally friendly system,” says master electrician Lothar Weber, who is responsible for complete system support at Stadtwerke Altensteig, “above all because the heat pump is operated with electrical power from a photovoltaic system. “

”Since the plants themselves emit heat during operation (up to 90 kW), a heat recovery system was also installed. A buffer tank is available for times when the CHP units are not being operated for reasons of cost-effectiveness – such as during the night or at weekends. “This is used to supply the heating network in the intervening periods, which means that almost no energy is lost,” Weber explains.

Intuitive operation – simple networking

The district heating network of the city of Altensteig supplies over 200 heating customers, primarily private households, but also schools, municipal buildings, the castle with museum, a library, and a bank – with maximum reliability for the customer as the core priority of service provision. Two of the cornerstones of the district heating network’s reliability and stability are the 27 Danfoss OPR 20 and 10 ECL Comfort 310 controllers. Depending on the outdoor temperature, they regulate the flow temperature to ensure optimum heat output and water heating within the buildings supplied. What’s more, the ECL Comfort 310 is extremely easy to operate – supported by a clear graphic display. “Our customers also appreciate our operating philosophy,” reports Gerd Schreiber, Product Portfolio Manager & Technical Sales Support at Danfoss GmbH. “We use meaningful symbols instead of difficult-to-understand abbreviated texts. This supports the intuitive operation.” The connected heat meters are read via M-Bus and all data are transferred to Leanheat® Monitor via the LON network.

Optimizing heat distribution

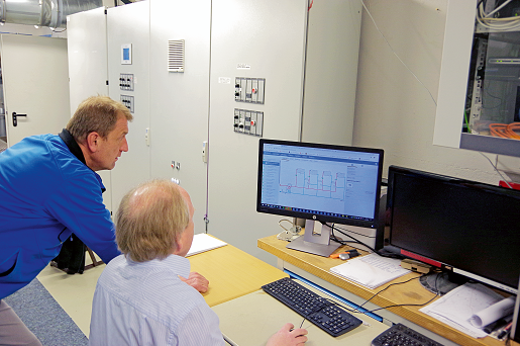

Now we come to the key advantage: with Leanheat® Monitor, district heating network operators maintain complete oversight and control. The newly developed software from Danfoss visualizes the entire district heating network: for example, all system components are displayed in the form of a map. At the same time, all data can also be viewed in tabular form. If the user clicks on a controller, a hydraulic system diagram appears immediately on the screen or display. “This shows, for example, how many heating circuits the controller controls and whether DHW heating is also connected. Sensor values and operating modes are also displayed,” explains Schreiber. Alarms marked in red can be located at a glance – and their operating data are also immediately available. However, the possibilities of the SCADA software go far beyond just visualization. The controller parameters can be set or the heating characteristic adjusted with min./max. values by remote access via the LON network. This is a tremendous advantage for system operators, as it enables them to use their expertise remotely to optimize the entire district heating distribution.

Documentation provides security

Leanheat® Monitor documents all controller data and displays it at the click of a mouse. The functioning of the district heating system can be monitored and any faults that may occur can be detected at an early stage. This is confirmed by Lothar Weber of Stadtwerke Altensteig: “Evaluations could not be simpler with Leanheat® Monitor. Temporal developments can be displayed at the touch of a button.” This is also of particular interest when customers report irregularities. Since Leanheat® Monitor makes it possible to identify the cause of these irregularities quickly, the time saving is enormous. Weber: “We can always see exactly what’s actually happening at the customer’s end.” This is particularly important at the points in the network that are furthest from the feed-in point – Leanheat® Monitor users always have oversight of the temperature gradient in the pipe network. Not only is it displayed graphically and in tabular form, but it is also documented over a selectable time period. Schreiber adds: “The documentation of operating parameters makes it very easy for operators to prove that they are meeting their supply obligation in the event that a customer reports or complains about a fault.”

A possible undersupply also quickly becomes apparent.

Web-based for mobile use

Leanheat® Monitor is also available on site for service technicians repairing faults or carrying out maintenance: the software is web-based and therefore runs with full functionality on mobile devices such as a tablet. The high data transparency in Leanheat® Monitor ensures fast, uncomplicated repair in the event of an error. What’s more, the software developers at Danfoss have also considered how to save time and effort in the billing process. The meter values recorded via Leanheat® Monitor can be immediately transferred to a billing system via a suitable interface upon request.

For greater efficiency

Efficiency is at the top of the agenda at Stadtwerke Altensteig, and Leanheat® Monitor supports this objective. “A district heating network is operating at a high level of efficiency when the return temperatures are as low as possible,” explains Gerd Schreiber. Limit values of the return temperatures are monitored by the controllers. If they were exceeded, a combined heat and power plant would have to be disconnected from the grid, for example. Leanheat® Monitor monitors the return temperature and identifies consumers that exceed the limits. Intervention by the network operator can therefore be carried out quickly and with little research effort at the right place – with the result that the stability of the district heating network always remains high. Stadtwerke Altensteig’s experiences with Leanheat® Monitor are promising: “Our already high expectations of the new software were met in every respect, in some cases even exceeded. Working with Leanheat® Monitor is easy, fast and clear,” says Lothar Weber with satisfaction.