Tailor-made spiral configuration to ensure a smooth operation for an Italian purification plant

eco center AG has replaced its current shell-and-tube technology with spiral heat exchangers from Danfoss. Clogging and weekly cleaning of the heat exchangers is now history - with a return of investment in just one year.

Since eco center AG replaced its current shell-and-tube technology with spiral heat exchangers from Danfoss, clogging and weekly cleaning of the heat exchangers is now history - with a return of investment in just one year.

In 2020, Danfoss supplied two spiral heat exchangers to the purification plant eco center AG, a society of the municipalities of South Tyrol and the Autonomous Province of Bolzano, Italy.

The company operates the most important waste disposal facilities including wastewater service sewerage and wastewater treatment) and supports environmental research projects to investigate the impact of its activities in the surrounding area.

Advantages

The best compromise between efficiency and functionality

Adequate free flow of suspended solids

Modularity (during maintenance, the second heat exchanger operates half power)

Easy to check and clean automatically.

Danfoss spiral heat exchangers offers a wide range of benefits

- Single-channel design that generates high shear rates which contribute to a self-cleaning effect, preventing clogging of the unit. Spiral heat exchangers are the perfect solution for challenging, high-viscosity media.

- Very compact solutions, our spiral heat exchangers have minimal space requirements. Despite their small stature, the long, curved flow paths allow for very high heat transfer coefficients up to twice as high as their shell and tube counterparts.

- Limited need for maintenance and cleaning ensures extended operational uptime. If the need for cleaning arises due to particularly difficult media, the hinged covers provide easy access to the entire heat transfer surface.

This enables eco center to operate at full capacity without losing valuable production downtime due to frequent cleaning and maintenance.

Related products

-

if (isSmallPicture) {

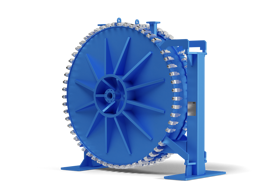

Spiral heat exchangers

Spiral heat exchangersExceptionally well-suited for sludges, slurries, waste water, fouling, liquids with high viscosity, and liquids that contain fibers and solids, our SONDEX® Spiral heat exchangers are the definitive solution for applications that require treatment of challenging fluids. The design allows for a countercurrent flow that makes it possible to achieve very close temperature approaches.