In this article we will look at one of refrigeration's most important applications, namely the cold storage room. We will dive into the specific features of cold storage and look at refrigeration of foodstuffs as a way of preserving their quality, including how temperature, humidity, and air-flow rate affects food quality.

Humidity and Air-flow Rate

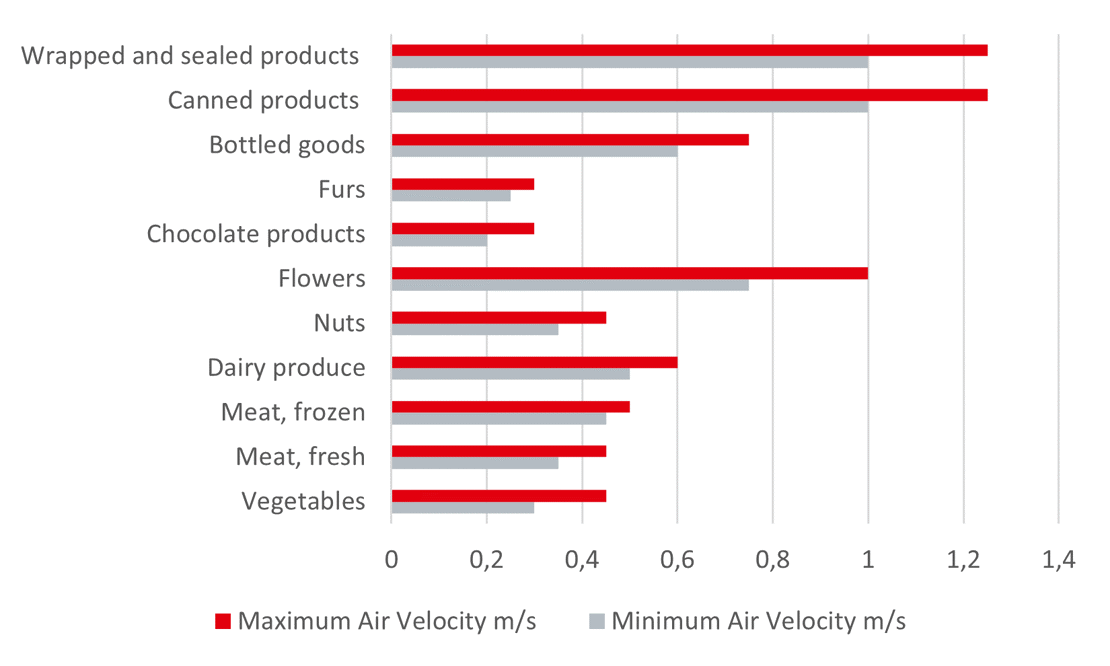

Humidity also affects food quality. Microorganism growth is also influenced by the moisture content of the ambient air. The moisture content of food products promotes the growth of microorganisms. In a low-humidity atmosphere, moisture will be removed from the product causing it to lose both weight and quality. We therefore need to maintain a certain level of humidity in the ambient air to keep food products fresh and prolong their shelf life. To continuously provide the proper moisture content, we need to maintain a constant temperature. In addition to the moisture content, the air-flow rate is also important for the quality of food products. The air exchange rate (the rate at which the existing air is replaced by fresh) is what ensures good air quality in the cold store, but the air-flow rate also affects the cooling and dehydration of the product: a higher rate increases the transfer of heat from the product but also its dehydration rate. An increased rate of dehydration means that more moisture will be removed from the product, leaving a lower moisture content. We therefore must provide for an appropriate air-flow rate within the refrigeration plant depending on the product being refrigerated. For example, fresh meat requires a lower air-flow rate than products that are wrapped and sealed.The airflow rate in m/s is shown below for some commonly stored products.

| Product | Humidity |

| Potatoes | 90-95 |

| Tomatoes | 90-95 |

| Apples | 90-95 |

| Garlic | 65-70 |

| Chicken | 95-100 |

| Fresh fish | 95-100 |

Conclusion

This concludes the first part of our consideration of cold storage rooms, in which we dealt with produce being refrigerated. Construction of a suitable cold storage room will be dealt with in the next episode in this series. This will concentrate on the practical challenges and requirements for setting up such an environment.