Robust, energy-efficient high-pressure pumps for industrial wastewater treatment

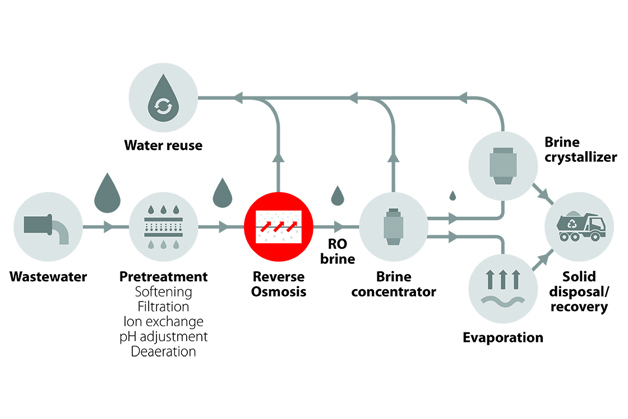

As water reuse and recycling grow alongside stricter environmental controls, companies and utilities increasingly turn to liquid discharge (ZLD) and minimum liquid discharge (MLD) to treat industrial wastewater. And because ZLD based solely on traditional thermal processes is highly energy intensive, membrane processes using reverse osmosis (RO) have emerged as an essential part of ZLD. Indeed, studies show that RO pre-treatment can reduce ZLD’s overall energy consumption by up to 75%.

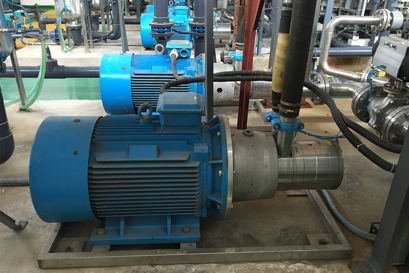

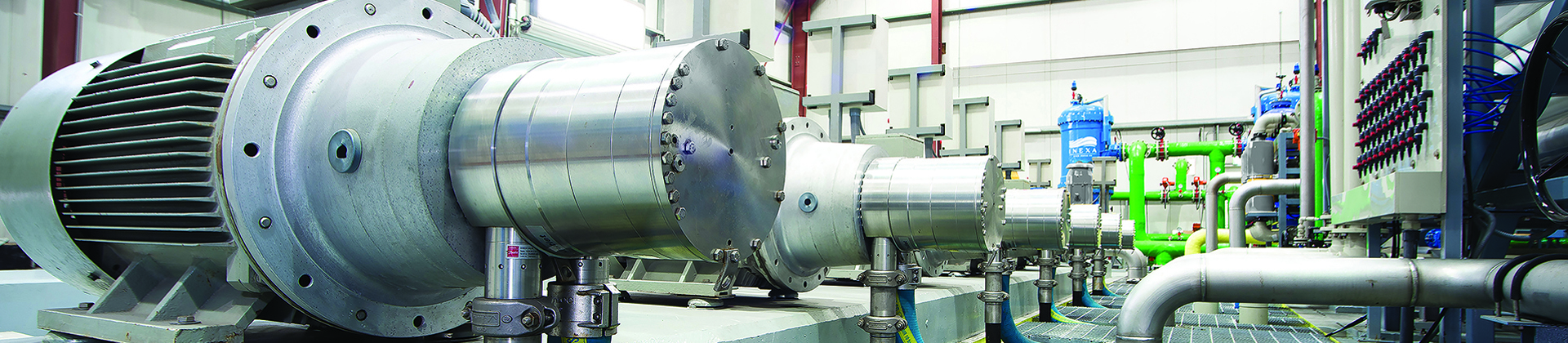

Danfoss APP pumps are particularly well-suited for such RO treatments. Due to their unparalleled efficiency rates of up to 92%, they reduce OPEX and emissions significantly compared to other high-pressure pump technologies. Moreover, this efficiency remains the same regardless of varying pressure rates up to 120 bar, and operators can depend on their field-proven history of simple maintenance and long service intervals. The new APP pumps with ceramics makes the Danfoss portfolio of reliable, energy efficient high-pressure pumps for wastewater treatment ideal for even more use cases. Monitoring system available for all APP pumps with ceramics.

Features and benefits

-

World-class efficiency - up to 90% at all operation points

-

Low complexity with few moving parts

-

Easy to operate and maintain

-

The pump is oil-free to avoid contamination

-

Easy scalability when coupled in parallel

-

Made of first-class Duplex steel to prevent corrosion in aggressive environments

Reduce the discharge of industrial wastewater by applying the highly efficient Danfoss APP W HC pump with an outlet pressure of up to 120 bar.

The new APP high-pressure pump with ceramics brings market-leading energy efficiency to even more wastewater applications with reduced particle sensitivity, simple maintenance, and field-proven reliability.

Customer collaboration contributes to pump innovation

Danfoss developed its latest APP high-pressure pump with ceramics in close cooperation with customers, including Veolia Water Technologies and TEMAK. Read our latest article to learn how demanding field tests help ensure reliability.

Download article

High-pressure pumps delivering up to 90% efficiency

With efficiency rates up to 90% at all operating points, the Danfoss APP W HC pumps are designed to produce the highest level of efficiency in ZLD (zero liquid discharge) and MLD (minimal liquid discharge) applications. The strong and extremely robust pumps are made of non-corrosive materials and guarantee high reliability and low operational costs over the service life.

The pumps are positive displacement pumps with axial pistons that move a fixed amount of water in each cycle. Flow is proportional to the number of shaft revolutions (rpm). Unlike centrifugal pumps, the APP W HC pumps produce the same flow at a given speed no matter what the discharge pressure.

The simple pump design allows easy installation, inspection, and maintenance. Furthermore, the pump operates without oil to prevent contamination. The pumps can be parallel-coupled in trains to fulfill the required capacity at any time.

Pump animation

The axial piston pump has a simple design with only a few parts.

Learn how the pump works in this video animation.

See animation

Product range

Save energy with a membrane-based process

ZLD/MLD systems can be operated with different processes. A way to reduce energy consumption is to use a membrane-based process.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Promotion material | APP high-pressure pumps with ceramics: Robust energy efficiency for demanding membrane technologies | English | Multiple | 02 Mar, 2025 | 1.4 MB | |

| Article | APP pump now with ceramics for energy efficient SWRO and wastewater treatment | English | Multiple | 05 Dec, 2023 | 1.1 MB | |

| Data sheet | APP W HC 15-24 Pumps Data sheet | Chinese | China | 10 Apr, 2019 | 1.2 MB | |

| Data sheet | APP W HC 15-30 Pumps Data sheet | English | Multiple | 22 Oct, 2019 | 753.5 KB | |

| Brochure | Save water, time and money with the new Danfoss APP W HC pump | English | Multiple | 16 Jan, 2019 | 1.9 MB | |

| Brochure | Save water, time and money with the new Danfoss APP W HC pump | English | United States | 16 Jan, 2019 | 1.9 MB |

Related products

VLT® AQUA Drive FC 202 controls all types of pumps and comes equipped with a cascade controller.

The range of high-pressure APP pumps is optimized for both landbased, off-shore and marine sea water reverse osmosis applications. Available with or without motor.

With a 3-in-1 design that integrates highly effective isobaric pressure exchangers with positive displacement booster pumps and electrical motors, active iSave® ERDs deliver big energy savings in small spaces. Covering train sizes from 200-3,000 m3/day

Related solutions

Case stories

China's zero liquid discharge legislation (ZLD) is driving increased use of RO technology to treat industrial wastewater. Danfoss APP pumps are increasingly in demand to make such ZLD projects as energy-efficient - and profitable - as possible.

To reduce the significant energy costs that result from wastewater being transformed from liquid to solids, companies are turning to RO treatment – and Danfoss APP pumps are helping to keep energy costs at a minimum due to high efficiency.