Extra protection for use in marine and heavy industries

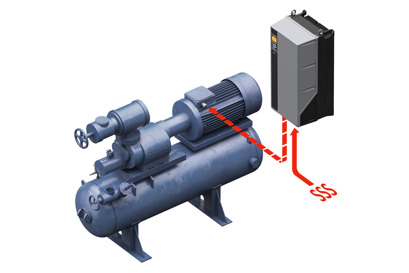

VACON® NXP Liquid Cooled drives are integrated in a sturdy enclosure making them ideal for a wide range of industries with harsh operating conditions.

Liquid-cooled AC drives can be used in many combinations, from a single dedicated frequency converter to large-scale common DC bus systems. Packed with features, these fully standardized enclosed drives maximize the utilization of space while minimizing overall lifecycle costs.

Thanks to the high degree of protection (IP54), these drives can be installed almost anywhere in a plant or on a vessel. This eliminates the load on air-conditioning systems in electrical rooms reducing costs and installation time, and makes them ideal for retrofitting.

Servicing is fast and easy. Features such as safe torque off (STO) and safe stop 1 (SS1) improve safety, and conformal coated circuit boards enhance reliability.

NXA, NXN, NXB and NXI configurations

Active Front-end (NXA), Non-regenerative Front-end (NXN), Brake Chopper (NXB) and Inverter (NXI) configurations are available.

For more information about these configurations please refer to the VACON® NXP Common DC Bus selection guide.

Supply voltages and power range

- 3 x 400-500 V...700-1100 kW

- 3 x 525-690 V...800-1550 kW

Features and benefits

-

Drive lifetime and reliability are enhanced due to sturdy cabinet protection

-

Floor space requirements and infrastructure needs are reduced as the compact design needs no air ducts

-

Investment savings as no large air-conditioning systems are needed due to minimal dissipation of heat loss to the air

-

Fulfills all relevant international standards and global requirements including marine, safety, EMC and harmonics approvals

-

Virtually silent operation as no large cooling fans are needed

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Case story | Abeking and Rasmussen WSV | English | Multiple | 03 May, 2023 | 4.5 MB | |

| Case story | Abeking and Rasmussen WSV - German | German | Multiple | 03 May, 2023 | 4.5 MB | |

| Case story | Abeking and Rasmussen WSV - Turkish | Turkish | Multiple | 22 Sep, 2023 | 4.5 MB | |

| Brochure | DrivePro Life Cycle Services - Chinese | Chinese | Multiple | 02 Apr, 2025 | 27.1 MB | |

| Brochure | DrivePro Life Cycle Services - Italian | Italian | Multiple | 01 Apr, 2025 | 26.7 MB | |

| Brochure | DrivePro® Services Overview | English | Multiple | 03 Feb, 2025 | 26.8 MB | |

| Brochure | DrivePro® Services Overview - German | German | Multiple | 28 Apr, 2025 | 26.7 MB | |

| Brochure | DrivePro® Services Overview - Korean | Korean | Multiple | 30 Dec, 2025 | 27.0 MB | |

| Brochure | DrivePro® Services Overview - Polish | Polish | Multiple | 30 Dec, 2025 | 26.9 MB | |

| Brochure | DrivePro® Services Overview - Portuguese | Portuguese | Multiple | 25 Mar, 2025 | 26.7 MB | |

| Brochure | DrivePro® Services Overview - Spanish | Spanish, Castilian | Mexico | 25 Mar, 2025 | 26.7 MB | |

| Brochure | DrivePro® Services Overview - US English | English | United States | 03 Feb, 2025 | 26.6 MB | |

| Case story | Electrosteel Castings Ltd | English | Multiple | 03 May, 2023 | 1.7 MB | |

| Case story | EMIT - Polish | Polish | Multiple | 02 Oct, 2023 | 7.5 MB | |

| Application guide | Encoder-less Safety using DOLD Module | German | Multiple | 08 Sep, 2017 | 6.1 MB | |

| Application guide | Encoder-less Safety using DOLD Module | English | Multiple | 15 Apr, 2017 | 5.9 MB | |

| Brochure | Engineering - Chemical and Pharma | English | Multiple | 17 May, 2022 | 37.7 MB | |

| Brochure | Engineering - Chemical and Pharma - German | German | Multiple | 14 Jul, 2023 | 37.8 MB | |

| Case story | Maximum Power for excavating uphill tunnels | English | Multiple | 24 Aug, 2023 | 6.9 MB | |

| Brochure | Mining and mineral processing | English | Multiple | 12 Nov, 2021 | 44.2 MB | |

| Brochure | Mining and mineral processing - Chinese | Chinese | Multiple | 12 Nov, 2021 | 44.4 MB | |

| Brochure | Mining and mineral processing - French | French | Multiple | 12 Nov, 2021 | 44.3 MB | |

| Brochure | Mining and mineral processing - German | German | Multiple | 12 Nov, 2021 | 44.3 MB | |

| Brochure | Mining and mineral processing - Polish | Polish | Multiple | 12 Nov, 2021 | 44.3 MB | |

| Brochure | Mining and mineral processing - Russian | Russian | Multiple | 12 Nov, 2021 | 44.2 MB | |

| Brochure | Mining and mineral processing - Spanish | Spanish, Castilian | Multiple | 12 Nov, 2021 | 44.2 MB | |

| Brochure | Product Overview | English | Multiple | 09 May, 2025 | 12.6 MB | |

| Brochure | Product Overview - Chinese | Chinese | Multiple | 21 Jul, 2025 | 12.9 MB | |

| Brochure | Product Overview - Czech | Czech | Multiple | 21 Aug, 2025 | 12.6 MB | |

| Brochure | Product Overview - French | French | Multiple | 16 Mar, 2023 | 11.4 MB | |

| Brochure | Product Overview - German | German | Multiple | 16 Mar, 2023 | 11.4 MB | |

| Brochure | Product Overview - Italian | Italian | Multiple | 09 May, 2025 | 12.8 MB | |

| Brochure | Product Overview - Korean | Korean | Multiple | 16 Mar, 2023 | 13.2 MB | |

| Brochure | Product Overview - Polish | Polish | Multiple | 16 Mar, 2023 | 11.9 MB | |

| Brochure | Product Overview - Portuguese | Portuguese | Multiple | 16 Mar, 2023 | 11.9 MB | |

| Brochure | Product Overview - Russian | Russian | Multiple | 09 May, 2025 | 12.7 MB | |

| Brochure | Product Overview - Serbian | Serbian | Multiple | 16 Mar, 2023 | 11.9 MB | |

| Brochure | Product Overview - Spanish | Spanish, Castilian | Multiple | 16 Mar, 2023 | 11.8 MB | |

| Application guide | VACON Condition-based Monitoring | English | Multiple | 23 Feb, 2023 | 1.2 MB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide | English | Multiple | 12 Jun, 2023 | 24.0 MB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide - Chinese | Chinese | Multiple | 19 Nov, 2021 | 40.8 MB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide - French | French | Multiple | 19 Nov, 2021 | 31.2 MB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide - German | German | Multiple | 19 Nov, 2021 | 31.1 MB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide - Hungarian | Hungarian | Multiple | 19 Nov, 2021 | 31.2 MB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide - Italian | Italian | Multiple | 19 Nov, 2021 | 31.2 MB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide - Japanese | Japanese | Multiple | 19 Nov, 2021 | 31.3 MB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide - Korean | Korean | Multiple | 19 Nov, 2021 | 31.4 MB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide - Portuguese | Portuguese | Multiple | 19 Nov, 2021 | 31.2 MB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide - Russian | Russian | Multiple | 19 Nov, 2021 | 40.6 MB | |

| Brochure | VACON NXP Liquid Cooled Selection Guide - US English | English | United States | 19 Nov, 2021 | 18.3 MB | |

| Operating guide | VACON-NX-Line-Voltage-Measurement-OG | English | Multiple | 27 Mar, 2023 | 13.0 MB | |

| Design guide | VACON® Hybridization Design Guide | English | Multiple | 14 Jan, 2017 | 3.8 MB | |

| Application guide | VACON® NX All in One Application Guide | English | Multiple | 03 Jun, 2025 | 7.5 MB | |

| Application guide | VACON® NX Marine APFIFF09V182 Appl. Man | Russian | Multiple | 15 May, 2018 | 4.1 MB | |

| Application guide | VACON® NX Marine APFIFF09V242 Appl. Man | English | Multiple | 28 Nov, 2023 | 3.3 MB | |

| Application guide | VACON® NX Shaft Sync Appl.M. APPFIFFV113 | Chinese | China | 15 Dec, 2015 | 1.5 MB | |

| Application guide | VACON® NX Sys Interf. APFIFF10V105 ApplM | Finnish | Multiple | 15 Dec, 2015 | 949.3 KB | |

| Application guide | VACON® NX Sys Interf. APFIFF10V244 ApplM | English | Multiple | 15 Apr, 2019 | 808.0 KB | |

| Operating guide | VACON® NXP Advanced Safety Options | English | Multiple | 12 Sep, 2024 | 14.1 MB | |

| Application guide | VACON® NXP AFE II ARFIFF05V070 Appl.M | English | Multiple | 15 Jun, 2021 | 1.1 MB | |

| Application guide | VACON® NXP CraneContr APFIFF20v099 ApplM | English | Multiple | 15 Jan, 2021 | 2.7 MB | |

| Application guide | VACON® NXP CraneContr APFIFF33V067 ApplM | Chinese | China | 15 Dec, 2018 | 13.8 MB | |

| Application guide | VACON® NXP CraneContr APFIFF33V067 ApplM | Portuguese | Multiple | 15 Dec, 2018 | 5.1 MB | |

| Application guide | VACON® NXP CraneContr APFIFF33V067 ApplM | German | Multiple | 15 Dec, 2018 | 5.2 MB | |

| Application guide | VACON® NXP Funct. Safety App.G for Lifts | English | Multiple | 15 Nov, 2019 | 1.4 MB | |

| Application guide | VACON® NXP HighSpeed APFIFF41V323 Manual | English | Multiple | 15 Jan, 2021 | 2.1 MB | |

| Application guide | VACON® NXP LineSynchII APFIFF44V120 AppM | English | Multiple | 15 Jun, 2021 | 1.9 MB | |

| Application guide | VACON® NXP Shaft Sync APFIFF11 Appl Man | English | Multiple | 15 Dec, 2015 | 1.1 MB | |

| Application guide | VACON® NXP SIA II APFIFF40V111 ApplM | English | Multiple | 28 Nov, 2023 | 3.0 MB | |

| Application guide | VACON® NXS-P FireM.PID ASFIFF11V210 AppM | English | Multiple | 15 Dec, 2015 | 229.5 KB |

Software

| Type | Software Characteristic | Name | Version | Language | Released | Status | Download | File type |

|---|---|---|---|---|---|---|---|---|

| System software | AC drive firmware | VACON NXP Firmware | 211 | Arabic; Bulgarian; Czech; Danish; German; Greek (modern); English; Spanish, Castilian; Estonian; Persian; Finnish; French; Irish; Hebrew (modern); Hindi; Croatian; Hungarian; Indonesian; Icelandic; Italian; Japanese; Kazakh; Korean; Lithuanian; Latvian; Macedonian; Norwegian Bokmål; Dutch, Flemish; Polish; Portuguese; Romanian, Moldavian, Moldovan; Russian; Slovak; Slovenian; Serbian; Swedish; Tamil; Thai; Turkish; Ukrainian; Vietnamese; Chinese | 25 Aug, 2025 | Released | 4.3 MB | .zip |

| System software | Option and fieldbus firmware | VACON® Advanced Safety Option Firmware | 004 | English | 15 Dec, 2019 | Released | 3.1 MB | .zip |

| System software | Fieldbus configuration file | VACON® NX OPTC3/C5 PROFIBUS GSD | 01 | English | 10 Jan, 2016 | Released | 748.0 B | .zip |

| System software | Fieldbus configuration file | VACON® NX OPTC4 LonWorks XIF | 01 | English | 10 Jan, 2016 | Released | 1.3 KB | .zip |

| System software | Fieldbus configuration file | VACON® NX OPTC6 CANopen EDS | 01 | English | 26 Feb, 2018 | Released | 2.7 KB | .zip |

| System software | Fieldbus configuration file | VACON® NX OPTC7 DeviceNet EDS | 01 | English | 31 Dec, 2011 | Released | 3.5 KB | .zip |

| System software | Fieldbus configuration file | VACON® NX OPTCP PROFINET GSDML | 01 | English | 18 Feb, 2015 | Released | 7.4 KB | .zip |

| Application software | Drive software | VACON® NXP Crane Application | 106 | English | 19 Nov, 2025 | Released | 5.8 MB | .zip |

| Application software | Drive software | VACON® NXP Power Generation Application | 041 | English | 19 Nov, 2025 | Released | 956.7 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPT-E6 CANopen Firmware | 015 | English | 16 Sep, 2025 | Released | 2.6 MB | .zip |

| System software | Option and fieldbus firmware | VACON® OPTBB EnDat Firmware | 009 | English | 24 Nov, 2025 | Released | 62.6 KB | .zip |

| System software | Fieldbus configuration file | VACON® OPTBE EnDat/SSI/BiSS C Firmware | 010 | English | 27 Mar, 2019 | Released | 36.4 KB | .zip |

| System software | Fieldbus configuration file | VACON® OPTCQ EtherNet/IP EDS | 01 | English | 07 Jan, 2015 | Released | 13.2 KB | .zip |

| System software | Firmware | VACON® OPTE2/E8 RS485 MultiProtocol | 004 | English | 16 Sep, 2025 | Released | 2.2 MB | .zip |

| System software | Fieldbus configuration file | VACON® OPTE3/E5 PROFIBUS GSD | 01 | English | 07 Jun, 2022 | Released | 13.4 KB | .zip |

| System software | Library | VACON® OPTE3/E5 TIA Portal Library | 014 | English | 07 Jul, 2020 | Released | 3.6 MB | .zip |

| System software | Fieldbus configuration file | VACON® OPTE9 EtherNet/IP EDS | 01 | English | 02 Sep, 2020 | Released | 72.1 KB | .zip |

| System software | Fieldbus configuration file | VACON® OPTE9 PROFINET IO GSDML | 01 | English | 02 Apr, 2020 | Released | 204.3 KB | .zip |

| System software | Fieldbus configuration file | VACON® OPTE9 SIMATIC PDM EDD | 01 | English | 15 Dec, 2019 | Released | 667.4 KB | .zip |

| System software | Library | VACON® OPTE9-EA TIA Portal Library | 01 | English | 15 Feb, 2018 | Released | 2.9 MB | .zip |

| System software | Library | VACON® OPTE9/EA EtherNet/IP Add-on Instructions | 01 | English | 15 Feb, 2018 | Released | 531.9 KB | .zip |

| System software | Option and fieldbus firmware | VACON® OPTEA Advanced Dual Port Ethernet Firmware | 011 | English | 25 Nov, 2025 | Released | 16.8 MB | .zip |

| System software | Configuration file | VACON® OPTEA PROFINET IO GSDML | 2.43 | English | 01 Dec, 2025 | Released | 242.5 KB | .zip |

| System software | Fieldbus configuration file | VACON® OPTEA SIMATIC PDM EDD | 01 | English | 12 Nov, 2018 | Released | 461.7 KB | .zip |

| System software | Fieldbus configuration file | VACON® OPTEC EtherCAT ESI | 01 | English | 19 Feb, 2020 | Released | 381.4 KB | .zip |

| System software | Library | VACON® PROFISAFE TIA Portal Library | 01 | English | 15 Feb, 2018 | Released | 2.4 MB | .zip |

| Software tools | VACON® Safe | 1.0.4.0 | English | 24 Jan, 2021 | Released | 3.8 MB | .zip |

Related applications

Compressors, wind turbines, extruders, pumps, fans, conveyors, crushers, thrusters, and propulsion, test-bench, crane, winch and power-conversion systems.

Draw upon expertise from Danfoss to optimize energy storage solutions using drives for power conversion both on board vessels, and in shore power supply for quieter and cleaner harbors.