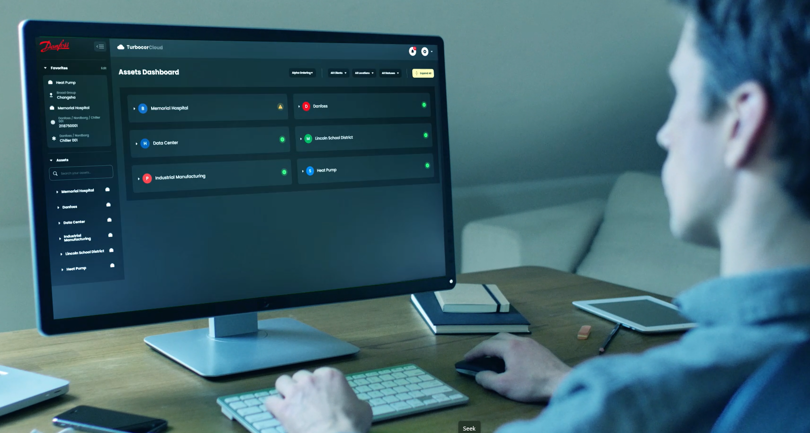

TurbocorCloud®: smart, connected compressors for enhanced performance

TurbocorCloud® leverages historical and real-time data to analyze performance, identify potential issues, and recommend proactive measures for maximizing efficiency and reliability. The portal delivers precise insights for planning service and maintenance, minimizing unscheduled downtime.

TurbocorCloud®

Seamless remote access to optimize compressor systems and prevent downtime.

What do you get with TurbocorCloud®?

Gain insights through data trending, facilitate collaboration, and offer value-added services by integrating compressor monitoring into PMAs. Deliver actionable health reports to end-users, predict failures, and optimize compressor staging for efficiency gains.

Enable seamless remote compressor monitoring and diagnostics for OEMs and TASPs. This tool empowers technicians to remotely access compressor data, enabling faster, more accurate diagnoses, reduced truck trips, and increased efficiency.

FAQ

FAQ TurbocorCloud®

What is TurbocorCloud?

• A dashboard allowing users to see the operation of any Turbocor compressor:

- Designed for TASPs and OEM’s, Service, Engineering, Quality, R&D, and Sales

- Intuitive and easy to use

- Latest design in data trending

• Compressor faults & events:

- Downloadable from dashboard

- Summary on Overview and Compressor Health Report pages

- All viewable on Fault and Event pages

- Acceptable format for submitting with Incident Reports & RMA Requests

• Compressor health report:

- Displays kW usage

- History of faults

- Upcoming service needs

• All the above provided as a subscription available in 1- and 2-year plans

Where does TurbocorCloud fit into my company?

OEM

Service

• A cutting-edge tool for OEM technicians:

- Provides a significant increase in tech efficiency

- Quick download of faults & events

- Advanced trending allows techs to make initial diagnosis ahead of jobsite visit

- Easily collaborate with other technicians through data sharing

• Preventative Maintenance Agreements (PMAs):

- Compressor monitoring can be now included into PMAs

- New value-add or service premium to secure additional contracts or revenue

- Distributable compressor health reports create a deliverable to end-user

R&D/Quality/Engineering

• New product launch:

- Useful to test compressor responsiveness to demand changes

- Can help to predict performance

- Provide visibility to issues ahead of catastrophic failures

• New or modified control schemes:

- Can help to identify opportunities for efficiency gains with compressor staging

- Monitor compressor trends to measure impacts from system controls (fan, pump, and cooling tower control)

• New product applications:

- Helpful for testing in ever-changing data center requirements

- Critical applications

- Can observe the impacts on changes in demand on compressor or chiller

Sales

- Easily provide case studies showcasing improvements in efficiency through historical trending

- Health report documentation

- Advanced notifications

- Preventative maintenance forecasting

TurbocorCloud vs Other types of remote monitoring

| Features | TurbocorCloud® | Chiller Controller | Advanced Chiller Plant Controller | IoT-Based Monitoring | Temporary Cellular Routers | Building Management Systems (BMS) |

| Trending Analysis | √ | √ | √ | √ | √ | √ |

| Consistent User Interface | √ | √ | √ | √ | √ | |

| User-Friendly Interface | √ | √ | √ | √ | √ | |

| Sustainable Deployment | √ | √ | √ | √ | √ | |

| Cost-Effective Solution | √ | √ | √ | √ | ||

| Rapid Deployment | √ | √ | √ | √ | ||

| Short-Term Deployment | √ | √ | √ | √ | ||

| Compressor Fault Visibility | 500 | 255 | 255 | 255 | 255 | 255 |

| Compressor Event Visibility | 5000 | 1064 | 1064 | 1064 | 1064 | 1064 |

| Compressor Fault Export | √ | √+ | √ | √ | ||

| Compressor Event Export | √ | √+ | √ | √ | ||

| Data Export Capability | √ | √ | √ | √ | ||

| Cellular Connectivity | √ | √ | √ | √ | ||

| Subscription Model | √ | √ | √ | √ | ||

| Reliable Global Connectivity | √ | √ | √ | |||

| Portability | √ | √ | √ | |||

| Turbocor-Specific Monitoring | √ | √ | ||||

| + If Turbocor's Software Monitoring Tool embedded into controller | ||||||

Is there hardware or software to be installed for TurbocorCloud?

| Gateway | 100471 |

| Ports - Ethernet (Disabled) | (1) RJ-45; 10/100 Mbps |

| Ports - Serial | RJ-50 10-pin (10P10C); RS-232/485; software selectable- RS-232 DTE (RXD, TXD, RTS, CTS, DTR, DCD, DSR, RI)- RS-485 (TX/RX+; RX/TX-); half-duplex |

| Dimensions | 118 mm x 88 mm x 35 mm (4.65 in x 3.46 in x 1.38 in) |

| Weight | 0.39 kg (0.86 lb) |

| Status LEDs | Power, SIM Status, LTE Signal Status, Signal Strength, Compressor Connection Status |

| Ingress Protection | IP30 |

| Power Input | 9 - 30 VDC, reverse polarity protection, 1.0 A maximum |

| Power Consumption | Configurable low-power modes; 1.5 W (light traffic flow), 3.5 W (peak data transmission); 1.25 W (low power mode, idle traffic) |

| Mounting | Direct Mount or DIN Rail Mount (hardware included) |

| Operating Temperature | −40 °C to 70 °C (−40 °F to 158 °F); device performance may be impacted above 50 °C (122 °F) |

| Storage Temperature | −40 °C to 85 °C (−40 °F to 85 °F) |

| Relative Humidity | 5% to 95% (non-condensing) |

| Environmental | ROHS3 |

| Safety | IEC 62368-1, CB, EN 62311, UL 121201 9th Edition, CAN/CSA C22.2 NO.213-17 |

| Direct Connect Antenna | 100473 |

| Compatability | Danfoss PN 100471 |

| Quantity Req'd | 2 |

| Application | Cellular |

| Frequency | 3G/4G/LTE (698-960/1710-2170-2500-2700 MHz) |

| Impedance | 50 Ohms |

| Gain | 0.6 - 2.6 dBi |

| Polarization | Linear |

| VSWR | 1.7:1 at 698-960, 1.5:1 at 1710-2170, 1.3:1 at 2500-2700 |

| Dimensions | 170 x 18 x 10 mm (6.69 x 0.71 x 0.39 in) |

| Mounting | Direct/SMA Male |

| Operating Temperature | -40° C to 85° C (-40° F to 185° F) |

| Material | PC/ABS UV stable |

| Weight | 25 g |

| External Antenna | 100467 |

| Frequency Range | 698 ~ 960MHz, 1710 ~ 2170MHz, 2490 to 2690MHz |

| Mounting | Screw-Mount [Permanent Mount] |

| Number of Bands | 4 |

| Applications | Worldwide 4G Bands including 3G and 2G |

| Antenna Type | Aerodynamic, Super Low-profile Vandal Resistant Housing |

| Ingress Protection | IP67 Enclosure |

| Dimensions | 216.24mm x 93.25mm x 30.95mm |

| Termination | SMA Male |

| RoHS Status | ROHS Compliant |

| ECCN | EAR99 |

What security measures does TurbocorCloud have in place?

• First, the cellular gateway communicates to the compressor BMCC via an RS485 or RS232 connection. It requires a separate communication bus to download data from the compressor. The communication bus from the chiller controller, while also through RS485, is on an entirely different communication bus. The two networks are physically separate and pose no risk to external threats to the chiller controller through the cellular connection.

• Second, TurbocorCloud Services does not have writing capabilities. There is no means for a user to write parameters, change setpoints, or adjust timers to the compressor.

• Other security information worth noting:

- Read only Compressor Access

- Encrypted Data Transfer

- Remote firmware management

- No local security credentials stored

- Secure Provisioning

- PKI Security Methods

- Encrypted Storage

- Protected hardware Ports

• Reduce attack vectors

• Minimum requirements scope

• Physical Access Security

What compressor models can be connected?

Software V1.1 (MVP release):

• All TTS, TGS, TTH, TGH, & VTX compressors

• All BMCC versions:

• Legacy BMCC (pre-4.X)

• 3.1.4

• 4.X

Do I have to purchase the Danfoss Gateway?

The Danfoss Gateway is supplied with custom firmware designed specifically for TurbocorCloud application to allow the transmission of data to our cloud. For TurbocorCloud to communicate and transmit data, the Danfoss Gateway is a requirement.

Only one Gateway is required per chiller if the following is true:

- There is one compressor per chiller -or-

- The dual RS485 IO board is purchased for multiple compressor chiller -and-

- Each compressor has a unique Modbus ID number -and-

- The communication is daisy-chained between each IO board

Can I use my own cellular carrier?

• The pricing for the Cellular TurbocorCloud subscription includes the costs for a cellular data plan. A different carrier is not required.

• A differing carrier has not been tested and cannot guarantee connection at this point in time

How do I connect to a single compressor chiller?

• If using the standard IO board containing both an RS232 and an RS485 connection, the RS232 9-pin serial connector can be utilized.

• If the optional dual RS485 board is used, the first RS485 port can be used for TurbocorCloud data transmission while the second port can be used for chiller control communication.

Will I lose the chiller controller's ability to communicate with the compressor?

• All chiller controllers that use the RS485 port will maintain communication with the compressor for sending demand signals.

• If a chiller controller uses the RS232 port for the Turbocor Software Monitoring Tool (SMT), this capability will be lost when using TurbocorCloud:

- This is true when switching to the dual RS485 IO board (the RS232 connection is removed)

- This is true if keeping the standard IO board as the TurbocorCloud gateway will use the RS232 connection for communication to the compressor.

How do technicians use the SMT if there is no longer access to the RS232 port?

• The connection made the TurbocorCloud can be disconnected while technicians are using the SMT as part of troubleshooting, calibration report creation, or setting changes

• With the standard IO board, simply disconnecting the RS232 port connection and reconnecting with their own cable can allow access

• With the new dual RS485 port, disconnect the TurbocorCloud connection and use that connection (RS485) to communicate with the compressor. This will require a different cable than would be used for the RS232 connection

Does the TurbocorCloud cellular plan use 5G?

• The SIM card automatically selects either an LTE, 4G, or 3G signal based on availability. The speed is of little concern due to the size of the data uploads. Signal strength is also of less concern if a signal exists (down to a single bar).

• If there is concern over signal strength, we offer multiple antenna options to move the antenna to a remote location, outside the chiller control cabinet or outside (for indoor applications)

What happens if a compressor or BMCC is replaced?

• The compressor or BMCC will be saved, and the name will reference be in the site tree as ‘retired’.

• The data will continue to be viewable as long as the data range from when the compressor was connected is selected.

Can the gateway be moved to different sites or connected to different compressors?

• The hardware (Gateway, SIM, IO Boards):

- These are portable and are not specific to any compressor

• Subscription:

- This is specific to a compressor serial number and is non-transferable.

- There is an exception if the compressor or BMCC has experienced a failure

What is the storage capacity and data limitations within TurbocorCloud?

• Compressor Faults:

- 500 viewable and downloadable

- Date range can be the from when compressor is first connected

- Viewable even when compressor is powered off, removed, and/or replaced

• Compressor Events:

- 2000 viewable and 5000 downloadable

- Date range can be from when the compressor is first connected

- Viewable when the compressor is powered off, removed, and/or replaced

• Compressor Data:

- Download All Data:

▪ Compressed to 15-minute intervals: Up to 7-days per download

▪ Expanded to 1-minute intervals: Up to 48-hours per download

- Download data in charts:

▪ If time range <=6 hours, data in 1-minute increments

▪ If time range >6 hours, data in 15-minute increments

Can TurbocorCloud portal or Dashboard be customized?

• Currently, the dashboard and health report cannot be customized to show different data.

• The trending page can show any number of customer selectable points.

• The date ranges for data, faults, and events can be customized.

What algorithms are built into TurbocorCloud?

• The current product at the time of launch will provide the expected change date for the softstart fan and the capacitor bank.

• There are no additional predictions, artificial intelligence, or machine learning built into the software.

• There are active plans to expand this into the offering but will require time to develop and test for reliability.

• Please capture any customer feedback for features they may like to see and report back to Product Managment.

Can a single gateway be used across multiple chillers?

• Yes, as long as each compressor has a unique address. The address is how the gateway can identify each compressor.

• The current defined limitation is 10 compressors; beyond this has not been tested.

• The RS485 communication effectiveness is limited by:

- Bus length required to connect devices

- Quality of the cable and terminations

- Volume and speed of data transferred

- Environmental conditions (noise, interference, etc)

Where is data stored?

- TurbocorCloud utilizes Microsoft Azure servers for data storage.

- Data is stored in the United States.

Related products

Danfoss Turbocor model TGS oil free compressors are available in 5 different models ranging from 40 tons to 150 / 140 kW to 540 kW utilizing ultra-low GWP R1234ze or R515B.

Danfoss Turbocor®model TTS oil free compressors are available in four different models ranging from 60 tons to 200 tons / 200 to 700 kW utilizing R134a or low GWP R513A.

Danfoss Turbocor® model TTH / TGH oil free compressors, optimized for high lift applications are available in two different models utilizing R134a or R513A (107 tons / 376 kW) or ultra-low GWP R1234ze and R515B (82 tons / 288 kW).