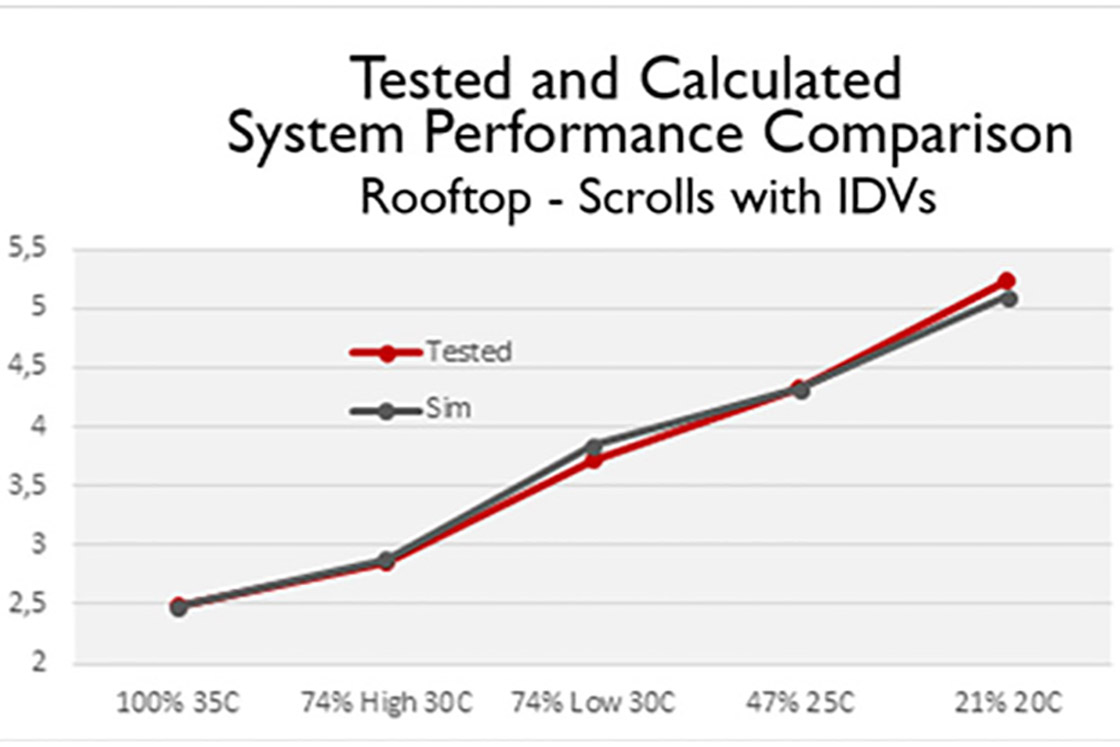

Danfoss has handed air conditioning OEMs a timely boost in their efforts to meet new seasonal efficiency targets – after new simulation tools and testing facilities confirmed the promise that a drop-in Scroll with IDVs compressor could yield a 7.3% system-wide gain.

Air conditioning companies worldwide are responding to challenging targets for energy efficiency. This is especially true in Europe, where Eurovent data showed in 2015 80% of today's air conditioning chillers would fail to meet Minimum Energy Performance Standards (MEPS).

In most major markets, new standards are being introduced based on weighted part-load figures to give a more accurate reflection of year-round power consumption.

Danfoss has launched a raft of measures to help its OEM customers respond:

New compressor technology – giving an immediate, system-wide seasonal efficiency boost from 6 to 12%

System seasonal / part-load efficiency simulation – to predict the efficiency impact of components and designs

Psychrometric testing rooms – allowing OEMs to validate their updated product ranges

Matthieu Stoll, Danfoss Global Marketing Manager for Air Conditioning Compressors, said: "A/C manufacturers have a lot of work to do, and quickly. At Danfoss, we're ideally placed to help."

"We have the most complete portfolio of components, which gives us in-depth knowledge about how they behave and about their value in the system. That means we can give OEMs immediate assistance at a system level, and long-term support."