The commonality of infrastructure systems is that they enable not only cost-optimized operation but also a cost-stable operation. District energy systems, whether district heating or cooling, are no different. By careful thermal planning, identification of possible heat or cool sources, and applying a favorable mix of thermal generation technologies, the district energy utilities can ensure optimal thermal generation cost, exceptional cost stability, and operational resilience. This article highlights the importance of choosing the optimal heat generation technology mix based on both investment costs (CAPEX) as well as operating costs (OPEX). By adopting multi source operation, district energy utilities can significantly reduce the thermal generation cost compared to single-source operation.

Authors

Introduction

District heating systems have many desirable attributes addressing our modern-day challenges. In Northern Europe, they have proved to be exceptionally effective in decarbonizing building heating demands and becoming the enablers of a future smart and efficient energy system. In Ukraine, they have proven to be exceptionally resilient to bombings during the Russian war on Ukraine. The Ukrainian cities with district heating systems, even as outdated as they are, have proven to have safer, more reliable, more stable, and more predictable heat supply than cities with individual heating. In the United Kingdom, district heating is recognized as an important solution to fight energy poverty. The key reason for the multi-criteria success of district heating is the fact that aggregating the demands of all connecting users enables access to a pool of diverse heat generation technologies. By properly combining heat sources and generation technologies, the district heating utility can ensure low heat costs, long-term cost stability, resilience to disruptions in energy vectors, and in the end, a reliable and future-proof heat supply operating in synergy with the overall energy system.

Multi-source heat cost optimization principles

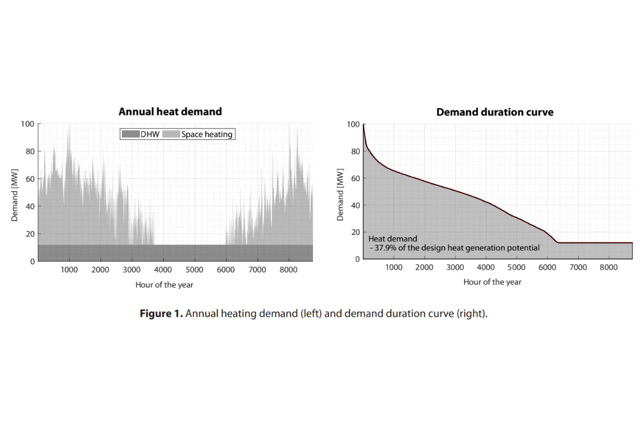

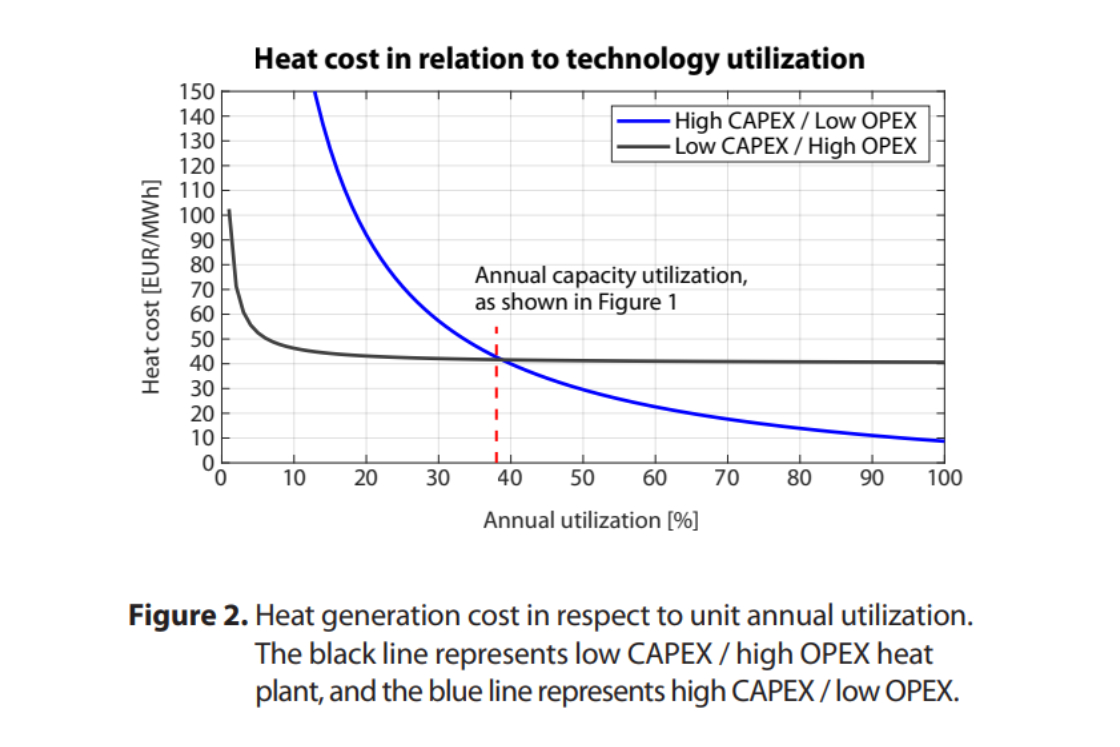

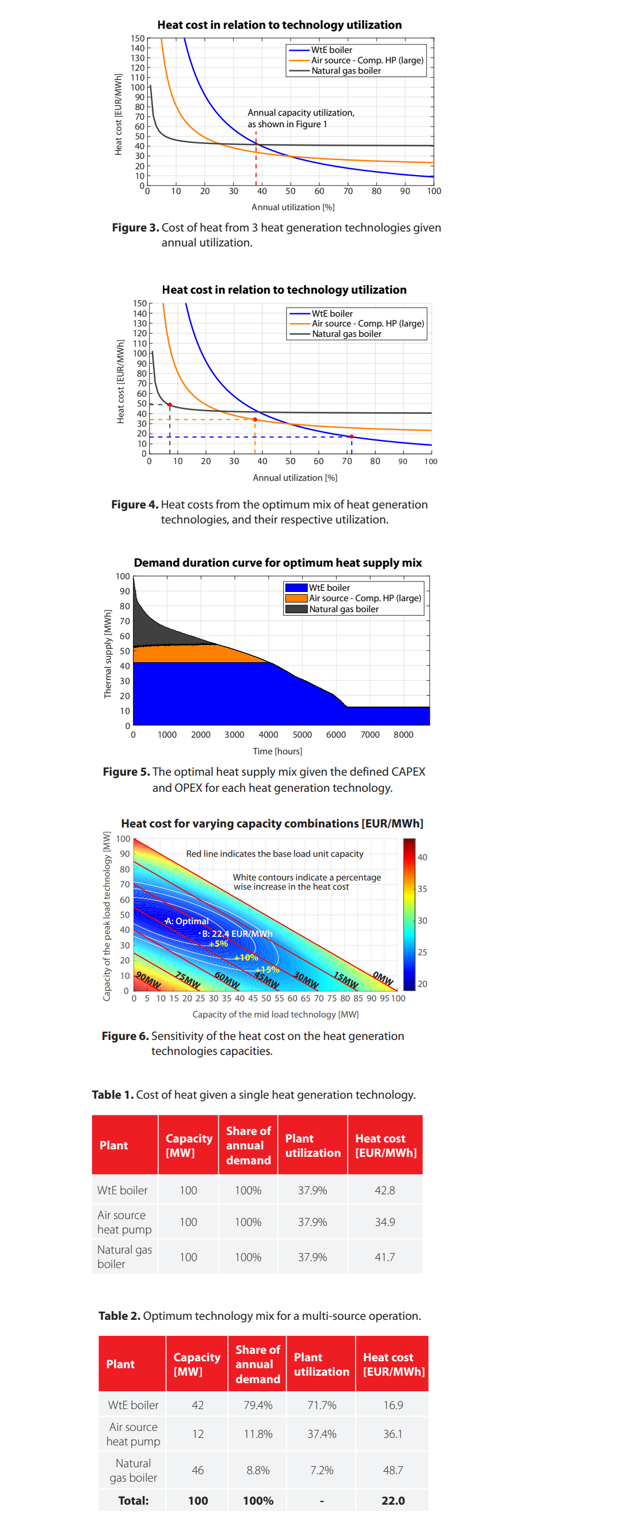

The basic steps for minimizing heat costs in district heating systems are:

Conclusions

By opting for multi-source operation and optimizing the heat generation capacities based on the relation between CAPEX and OPEX, district energy utilities can achieve multi-fold benefits, such as:

- Reduced thermal generation cost compared to a single energy vector strategy.

- Long-term stable and predictable thermal generation costs, as thermal generation cost from base load plants, will primarily be based on the initial investment cost and significantly less on operating the thermal plant.

- Significant opportunities to optimize which heat generation technologies to operate at any given time, for example, based on the cost of the input energy (electricity, fuel, surplus heat, renewables).

- Optimizing parameters other than cost, such as flexibility, can enable a heat generation mix that offers additional opportunities to take advantage of local conditions and energy spot markets, e.g., balancing services to the power system.

Another important conclusion from above is that in district heating, the heat cost sensitivity to the heat generation technology mix is low. With the low heat cost sensitivity district heating enables a wide range of technology combinations with stable and low heat costs. This is

important as new systems can be built with long-term planning, e.g., starting with a cheap peak load boiler and later when the system grows to build the CAPEX-intensive base load technology. This heat cost stability further enables district energy systems to take a leading role in the future integrated energy system, with enormous upside potential and limited risk.

For maximizing the benefits of multi-source operation, thermal energy storage options, and sector coupling potentials, district heating utilities can take advantage of digitalization options for optimizing the whole heat supply system, from the end-user to the heat generation, see [3].

By embracing the benefits and opportunities the infrastructure offers, district energy systems can ensure their relevance today and in the future.

Related solutions

-

if (isSmallPicture) {

District heating

District heatingUnlock the grids full potential with end-to-end district energy solutions and get actionable insights enabling continuous optimization and optimal temperature control on both demand and supply side.