District energy (district heating and cooling) is here to stay – with the green transition, it is more relevant than ever before. District energy has been around for some time and its development makes it a key solution to decarbonize heating and cooling.

During the years it has developed to fulfill the demands as they came up, typically driven by the demand for reduced investment and heat costs. It also adapted to lower equipment space demands, concerns of energy efficiency, and reaching sustainable goals. The development is categorized into 4 generations that indicate major changes in technology.

How did the systems change and develop, what sources and technologies have been and are in use today? What are the new upcoming technologies? Find all the answers below.

From steam to sector integration

Future developments: what is coming next?

Currently, most district heating (DH) schemes being operated are categorized as being at the stage of 3rd generation DH technology starting its transition to the 4th generation to address the challenge of the future non-fossil and renewable-based energy system. To meet the demands of the future energy system, existing DH schemes will transition into the next generation, the 4th, and the most advanced generation.

There is a lot of talk around district energy generations in the industry about new upcoming generations. At the same time, it is becoming clear that the proposed development from the 4th to the 5th generation is not at all sequential, but rather parallel.

Low temperature or ambient temperature district heating?

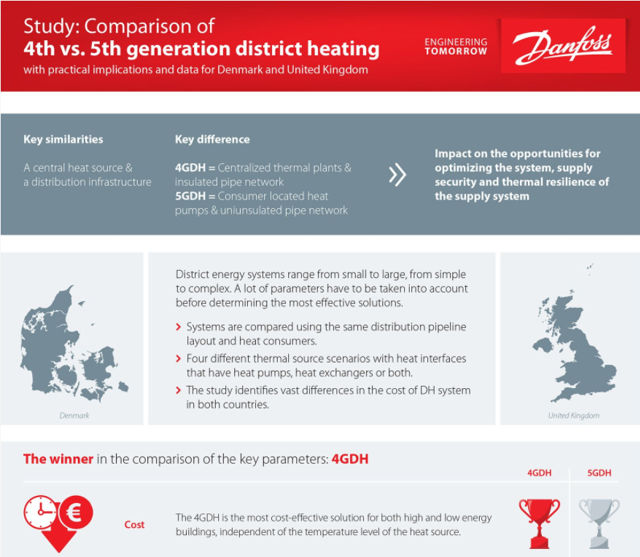

Our experts from the Danfoss' Application Center, Oddgeir Gudmundsson and Jan Eric Thorsen, have recently published a study where they compare the 4th and 5th generations. They base the comparison on key parameters, such as cost-effectiveness and flexibility, while the study is applied to Denmark and United Kingdom.

For locations investigated, the study reveals that the 4th generation remains the most attractive solution in light of the costs of establishing and operating the system. The study concludes that 4th generation district heating is not only more cost-effective compared to the 5th generation, it also performs better when it comes to security, reliability, flexibility, and resilience.

You can access the complete study on ScienceDirect or explore the resources below: