In the HVAC market, the term “EC motor” is commonly understood to mean a specific type of motor, which many users associate with compact construction and high efficiency. EC motors are based on the idea of using electronic commutation (EC) instead of conventional carbon brush commutation for DC motors. For this purpose, manufacturers of these motors replace the rotor winding with permanent magnets and incorporate commutation circuitry. The magnets boost efficiency, while electronic commutation eliminates the mechanical wear of carbon brushes.

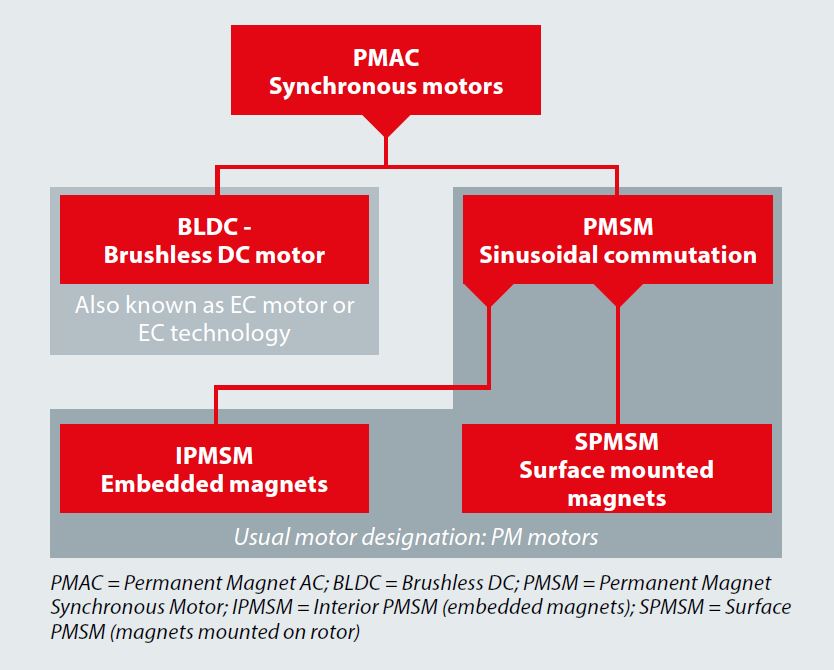

As the operating principle is based on that of a DC motor, EC motors are also called brushless DC (BLDC) motors. These motors are generally used in low power ranges of a few hundred watts. Motors of this type used for applications in the HVAC sector take the form of external rotor motors and cover a wide range of powers, presently extending to approximately 6 kW.

The technology

Due to the built-in permanent magnets, permanently excited motors do not need a separate excitation winding. However, they need an electronic controller that generates a rotating field. Operation directly from the mains is generally impossible, or in many cases only with reduced efficiency.

To drive the motor, the controller (e.g. a frequency converter) must be able to constantly determine the current position of the rotor. Two methods are used for this, either with or without feedback on the current rotor position provided by a sensor or an encoder.

A basic difference with permanently excited motors is the waveform of the back EMF (Electro Motive Force). When operating as a generator, a motor with permanent magnets produces a voltage known as the back EMF. To ensure optimum control of this type of motor, the controller must match the waveform of the supply voltage as closely as possible to the waveform of the back EMF.

In the case of BLDC motors, manufacturers use square-wave commutation due to the trapezoidal voltage waveform. Permanently excited synchronous motors (PMSMs) have a sinusoidal back EMF and therefore operate with a sinusoidal voltage (sinusoidal commutation). A further distinction is made between sinusoidally commutated motors depending on whether the magnets are glued onto the rotor (SPMSM) or are integrated into the rotor laminations (IPMSM). Due to these somewhat unwieldy abbreviations, the term ”PM motor“ is often used in practice to refer to motors with sinusoidal commutation.