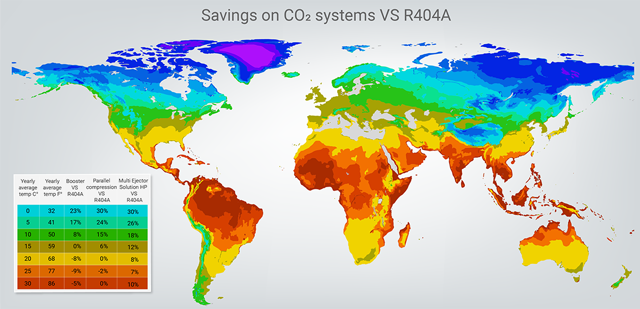

Around the world, there is little doubt that CO2 is fast becoming food retailers’ refrigerant of choice.

At Danfoss alone, we’re currently seeing supermarkets switching to CO2 refrigeration systems at a rate of around 10,000 a year—and that number is growing fast. Meanwhile, alongside the traditional large applications, CO2 is being used in a broader range of settings than ever, including very small systems like remote condensing units.

There are several reasons for this. Partly, it’s being driven by the global push to move away from HFCs in favor of natural refrigerants. Many HFCs have a global warming potential (GWP) more than 1,000 times higher than CO2, and increasing regulation is creating refrigerant cost and availability issues.

But it’s also because many of the traditional obstacles that once prevented people choosing CO2 no longer apply—making it easier to use its unique properties to increase efficiency and cut heating costs.

-

if (isSmallPicture) {

CO₂ in food retail

CO₂ in food retailDanfoss has pioneered CO₂ refrigeration systems for more than 10 years. Learn more about our CO₂ refrigeration solutions for supermarkets here.

-

if (isSmallPicture) {

Smart Store

Smart StoreThe Smart Store solution enhances food safety and brings down the energy bill by integrated and smart control of refrigeration, HVAC, lighting and other applications.