Your go-to newsletter for technical updates and latest changes in refrigeration and industrial solutions—delivered nearly every month.

Danfoss Tech Insider keeps you up to date with the latest developments in the Cooling and Industrial Products portfolios from Danfoss Climate Solutions. Each edition offers a quick overview of key technical updates and product news, with direct links to relevant documentation and further details. Published monthly, Tech Insider ensures you’re always informed about the latest innovations and changes across our products and solutions. We hope you enjoy reading Danfoss Tech Insider and find it both useful and inspiring!

Table of contents

- Introduction of the new DCR C range of replaceable solid core filter driers

- New 2x cables for ICAD actuators

- Additional Schrader port for Optyma™ A1 & A2L/A1 packaged Slim Pack W05 ranges

- Climate Solutions – BOCK®: Digital provision of assembly instructions

- New AK-SM 800A Danux available (4.14.017.194)

- New and updated content

Commercial Refrigeration

Introduction of the new DCR C range of replaceable solid core filter driers

We are pleased to announce the introduction of the new Danfoss ELIMINATOR® DCR C range of replaceable solid core driers. This latest innovation is designed to provide reliable system protection for refrigeration and air conditioning applications using A1, A2L, and A3 refrigerants.

Key benefits of the DCR C range:

- Universal compatibility: the DCR C range works seamlessly with A1, A2L, and A3 refrigerants, eliminating the need for second-guessing.

- Robust performance: certified for 50 bar MWP, the DCR C range is ready to handle the toughest conditions.

- Global compliance: PED Cat II approved, with UL approval anticipated in Q1 2026, ensuring adherence to international standards.

- Streamlined selection: a simplified portfolio that saves time and reduces errors.

- Wide temperature limit: operates effectively from -40 °C to 120 °C, accommodating diverse conditions for heat-pump or reversible systems.

Availability & migration timeline:

- Samples available from week 48, 2025 for a ramp up in 2026.

- Migration from DCR and DCR/E to DCRC: given the benefits of DCRC, a migration shall be considered for China, APA, Europe, TMA and India, from March 2026, based on aligned regional plans.

Additional Schrader port for Optyma™ A1 & A2L/A1 packaged Slim Pack W05 ranges

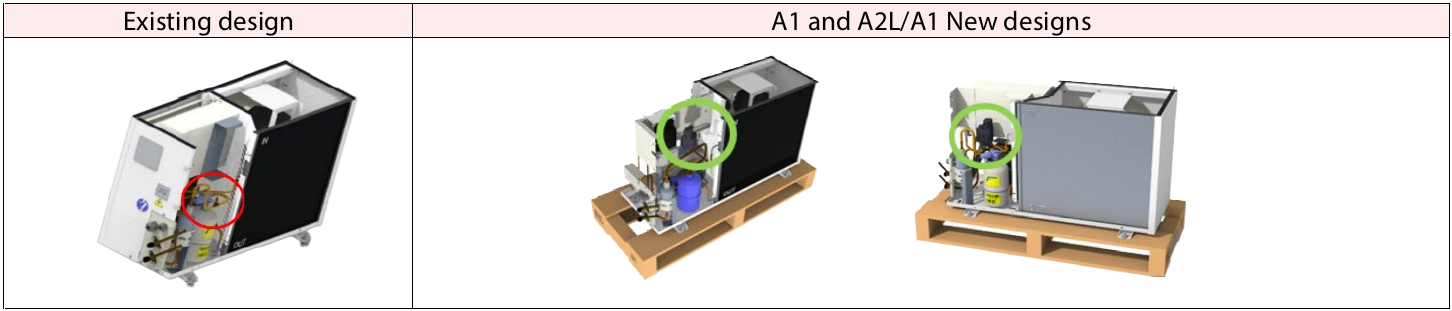

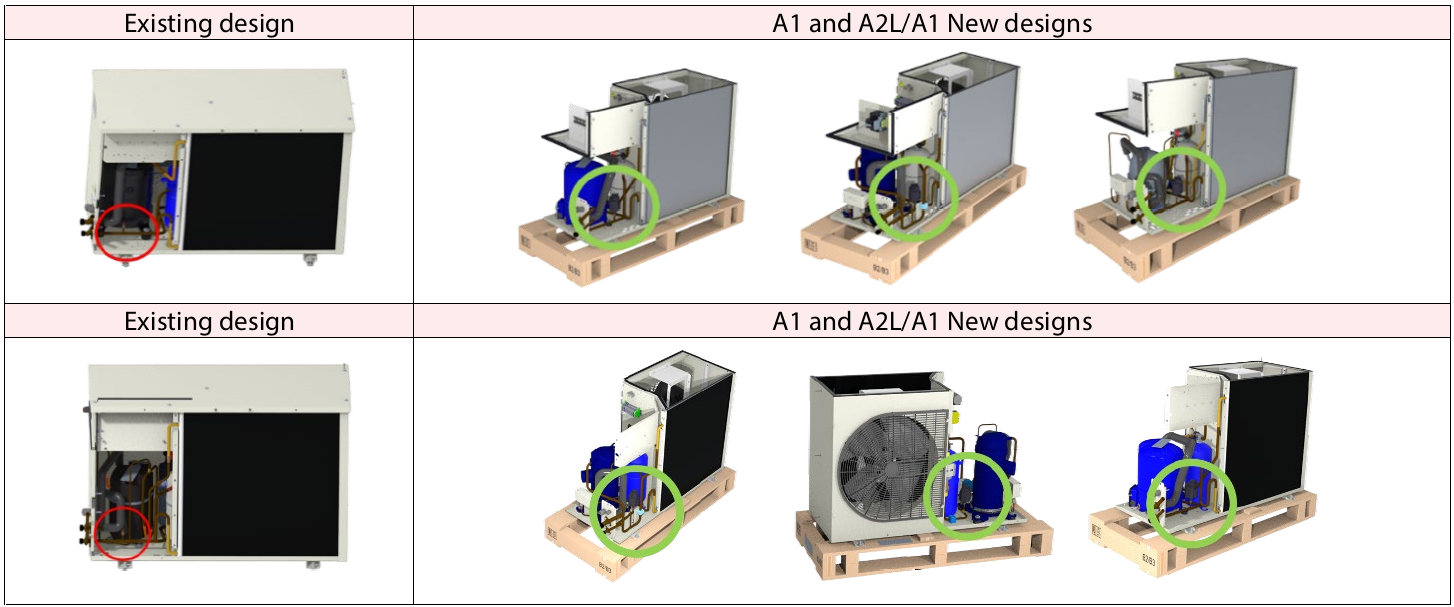

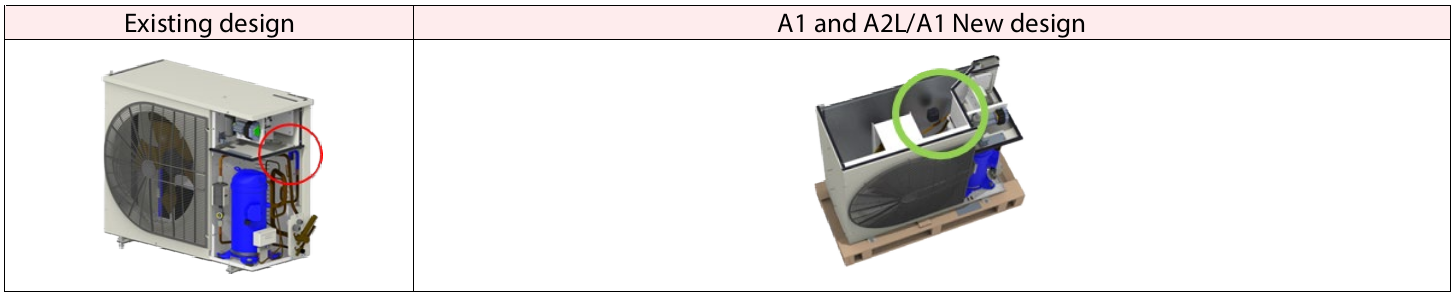

As part of our ongoing product upgrades to the Optyma™ Slim Pack A1 and A2L/A1 ranges W05, Danfoss has modified the liquid line piping and added a Schrader port. This allows the unit to be equipped with accessories such as the Danfoss XGE-EC fan speed controller (Danfoss code 061H3246) for A2/LA1 B3 chassis unit equipped with EC fans, or Danfoss XGE-2CIQ01 fan speed controller (Danfoss code 061H3148) for A1 B1 and B2 chassis equipped with AC fans.

Service valve with braze type connection

B1 chassis

B2 chassis

B3 chassis

For existing field replacement, customers need to adjust the tubes for suction and liquid lines with the extended service valves.

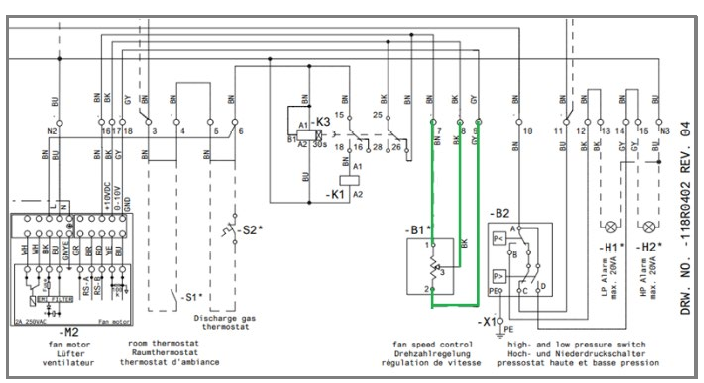

For modified products fan speed controller can be added directly before or after commissioning with Schrader valve support. Electrical wiring should follow stat of the art and the wiring diagram from our instruction manuals:

- A1 units: AN40143613378401-010302.pdf

- A2L/A1 units: AN37261865152502-010602.pdf

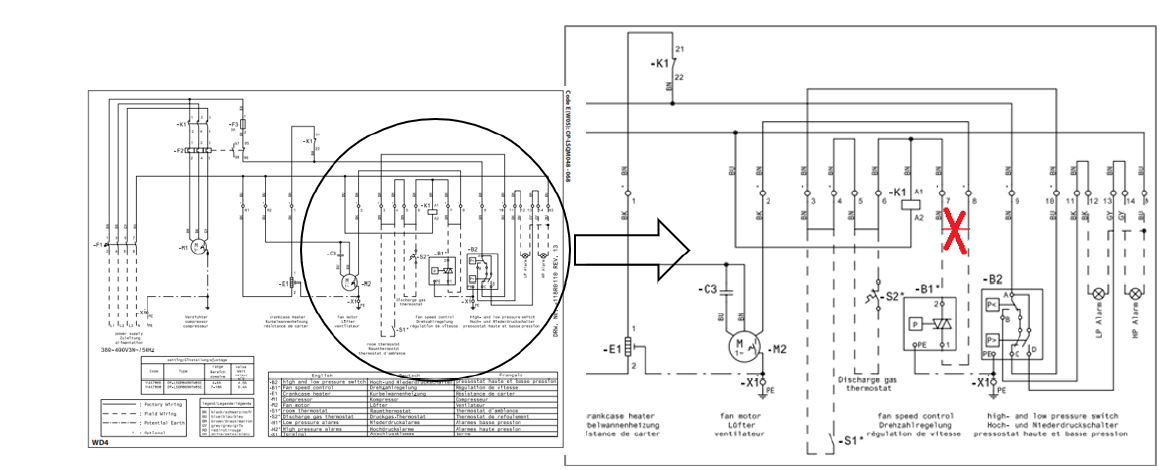

Following the wiring diagrams you can experience 2 cases (example for single phase unit):

1. For B1, B2 and B3 chassis, AC fans XGE-2CIQ01 controller, Danfoss code 061H3148

• Remove the bridge 7 to 8 and Connect 2 to 7 and 1 to 8

2. For B3 chassis, EC fans XGE-2CIQ01 controller, Danfoss code 061H3248

2. For B3 chassis, EC fans XGE-2CIQ01 controller, Danfoss code 061H3248

• Remove connection between 7 and 9 and R3 potentiometer connection R3

Implementation is already done, serial number on week 24 28 and 31 2023:

B1 panels, Serial number: 179790CG3123,

B2 panels, serial number: 179243CG2823,

B3 panels, serial number: 178973CG2423.

Update - MTZ 4-cyl compressors qualified with R454A/C and R455A

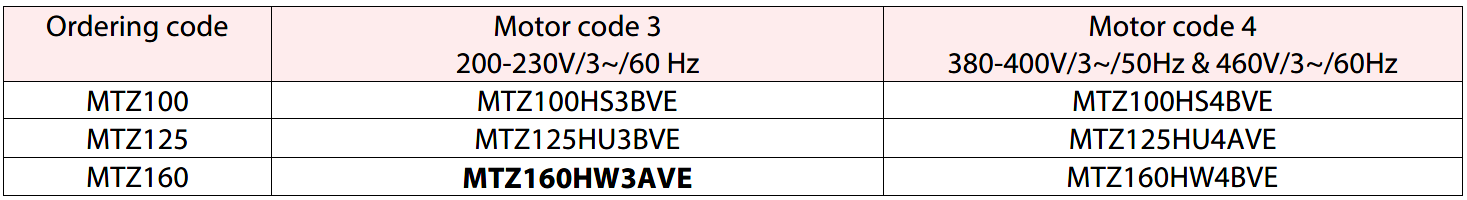

We are pleased to announce the addition of the MTZ160 motor code 3 model to our A2L qualification program and its implementation into production.

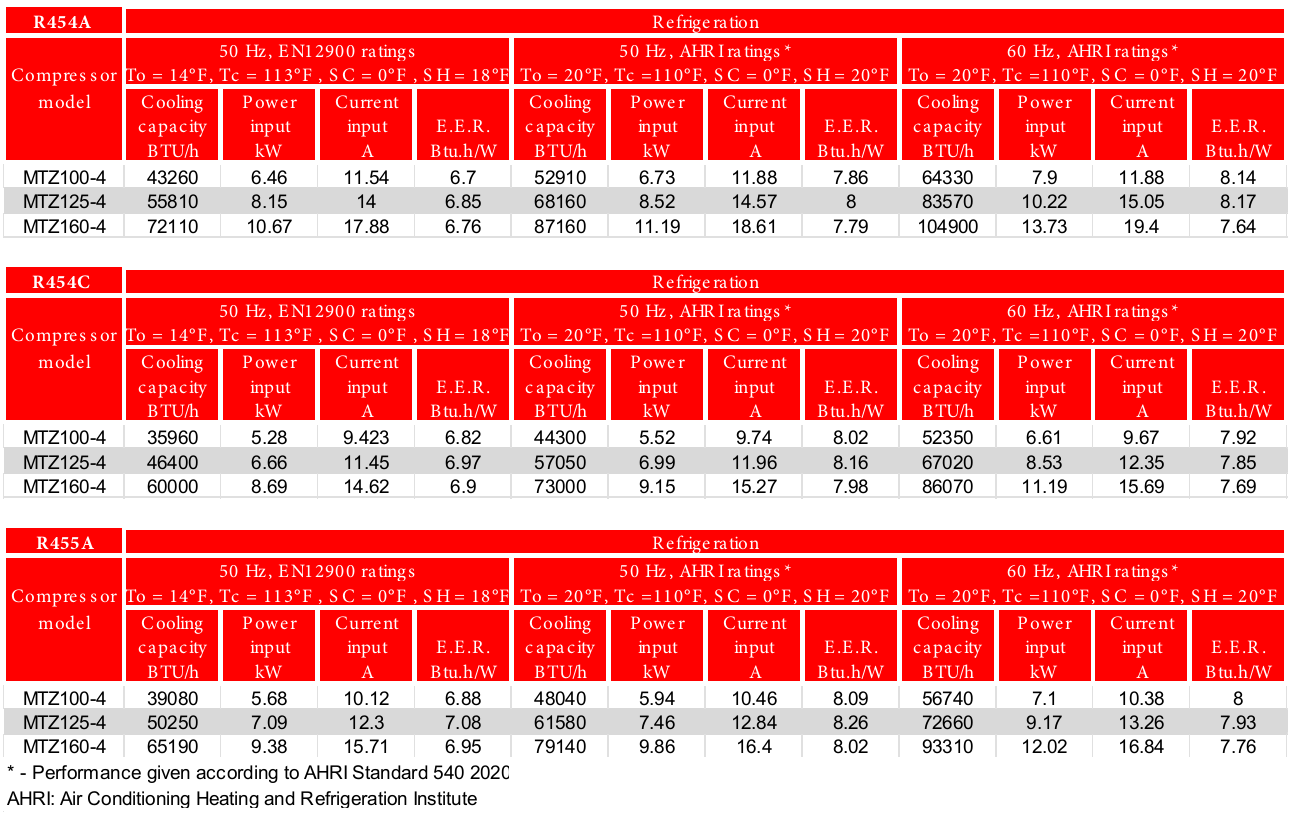

The MTZ models listed below are qualified for use with refrigerants R454A/C and R455A, classified in Refrigerant Group 1. R454A has a GWP of 238, while R454C and R455A have a GWP below 150. These refrigerants are classified as A2L, indicating low flammability properties. Please refer to European regulations (EN378, EN60335) and EPA rulings in the US for safe use. Outside of Europe and the USA, consult local regulations.

The following compressor models are qualified for use with R454A/C and R455A:

All compressor models, except the MTZ160 motor code 3, are qualified with R454A/C and R455A starting from July 2025. The MTZ160 motor code 3 is approved starting September 2025, with the first serial number following the change implementation being 1009521266.

R454A/C and R455A are zeotropic refrigerants with a temperature glide of about 6 to 12K and must be charged in the liquid phase. Despite the MTZ and NTZ compressors being loaded with 175PZ, R454A/C and R455A can significantly dilute the oil. To prevent lubrication issues, a crankcase heater must be used. This heater protects against off-cycle refrigerant migration and is effective if the oil temperature is maintained 8–10K above the saturated low-pressure temperature of the refrigerant. Tests should be conducted to ensure the appropriate oil temperature is maintained under all ambient conditions.

A PTC crankcase heater is recommended for all stand-alone compressors and split systems, as they are self-regulating. In extreme conditions, such as very low ambient temperatures, a belt-type crankcase heater may be used in addition to the PTC heater. The belt crankcase heater should be positioned on the compressor shell as close as possible to the oil sump for optimal heat transfer.

There is no change in the ordering process; compressor codes remain the same. Compressor nameplates for Refrigerant Group 1 will be adopted accordingly, as informed in FRCC.EN.431.A1.02 (Compressor nameplate: Group 1 and 2, PED MTZ/NTZ One Cylinder Models). Compressors are also marked with a flammable refrigerant logo. For more information, please refer to the CoolSelector2 selection program available at www.danfoss.com.

Nominal performance data:

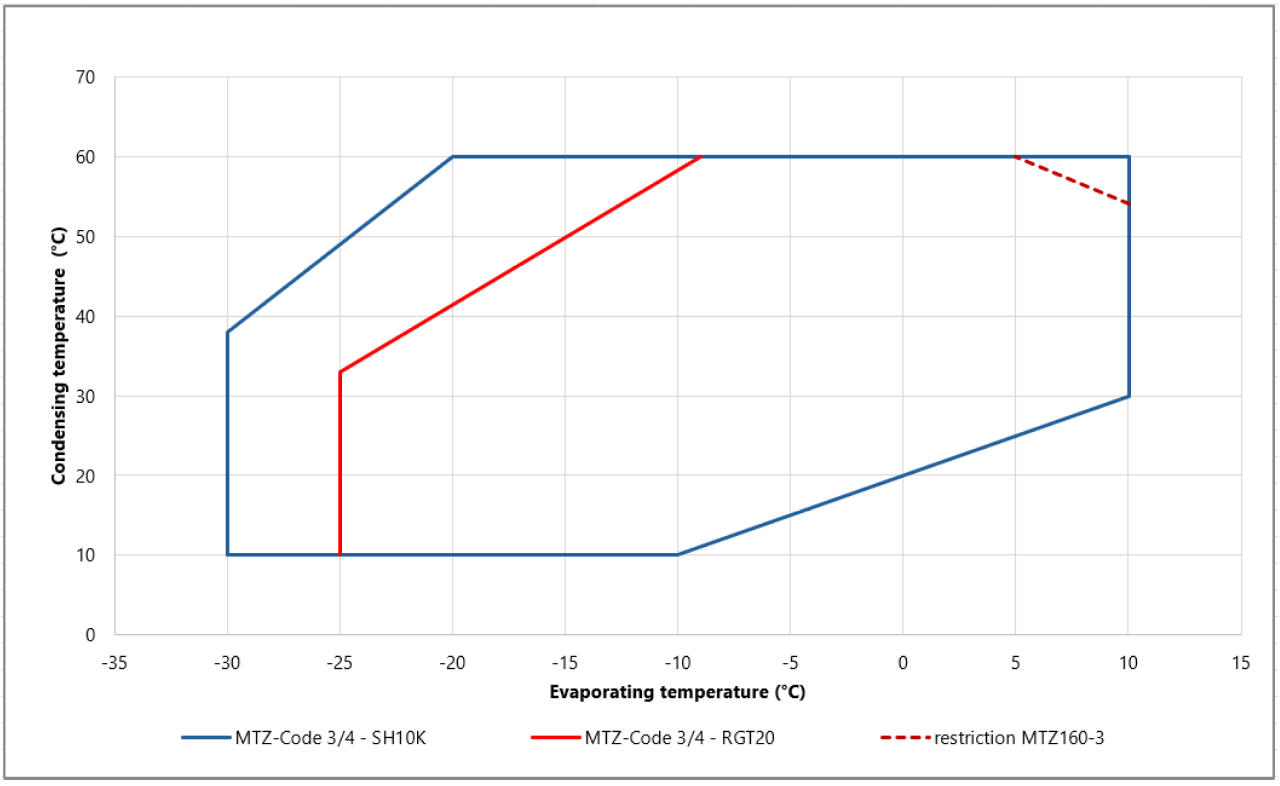

Please follow the operating map presented below.

Climate Solutions – BOCK®: Digital provision of assembly instructions

Summary

As part of our commitment to environmental sustainability and enhanced customer service, Danfoss is transitioning to a digital format for assembly instructions for BOCK® compressors. Printed instructions will no longer be included in compressor packaging. Instead, comprehensive instructions will be readily available on the Danfoss website.

If needed, instructions in paper format can be requested with delivery within one month.

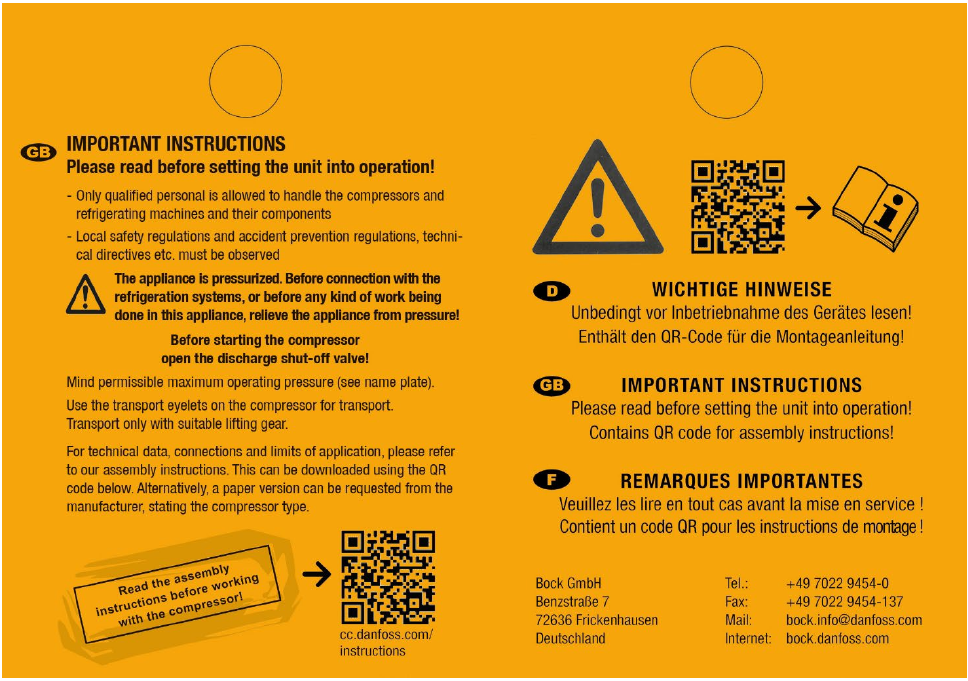

The digital instructions are accessible via a QR code found on the compressor tag or via the website URL cc.danfoss.com/instructions for easy access.

Compressor tag with QR code:

Description

In alignment with our eco-conscious initiatives, Danfoss will be dematerializing printed instructions within compressor packaging. This transition does not only reduce paper consumption but also provides customers with the most up-to-date information regarding product evolutions, including new refrigerant qualifications and expanded performance maps.

Detailed instructions can be accessed at the following URL: cc.danfoss.com/instructions.

Affected products

This change affects all BOCK® products, except for ATEX and UL compressors.

Customer impact

The transition to digital instructions will not affect the compressor's functionality, performance or safety in any way. This change solely pertains to the method of accessing product instructions.

Verifications

The transition complies with European Regulation on Machinery (EU) 2023/1230 (replaces Directive 2006/42/EC) for incomplete machinery, defining mandatory health and safety requirements that machinery products must fulfil. Article 10 paragraph 7 thereof permits the sole digital publication of operating instructions, if they are easily accessible in the long term via barcode or URL on product or packaging, and are available in paper form on request.

Implementation

The change will take place on 1st December and will be gradually implemented. The change does not affect compressor parts numbers. Implementation is only valid for compressor which are produced in Germany and Czech Republic.

Online Support

You can access and download detailed product information from Product Data Tool in the Partner Portal: Partner Portal/Product Data Tool

Food Retail

New AK-SM 800A Danux available (4.14.017.194)

We have received reports describing issues related to the creation and deletion of users in the AK-SM 800A System Manager.

To address this, a new Operating System (Danux) file has been released — version 4.14.017.194. A bug was identified in a Linux library responsible for user management. This issue caused the generation of lock files preventing normal user operations such as adding or deleting users. The fix implemented in Danux v4.14.017.194 automatically removes these lock files, thereby restoring full user management functionality.

If your System Manager shows symptoms of being unable to add or remove users, please install the updated operating system Danux v4.14.017.194 following the best practices below.

Software installation

Perform a unit backup and check for any open alarms before proceeding with update.

Install Danux 4.14.017.194.lpk)

- Using StoreView Browser 5 / StoreView Web select OS update and proceed with Danux upgrade

- Allow a few minutes to pass with the new OS installed

Important notes

This file size package is large and depending on your network speed may take 10+ minutes to complete. Do not interrupt power during the OS update. For systems utilizing DHCP it is advised that this update is performed locally, as IP address change is possible after re-booting.

Software can be found on Danfoss homepage:

Industrial Refrigeration

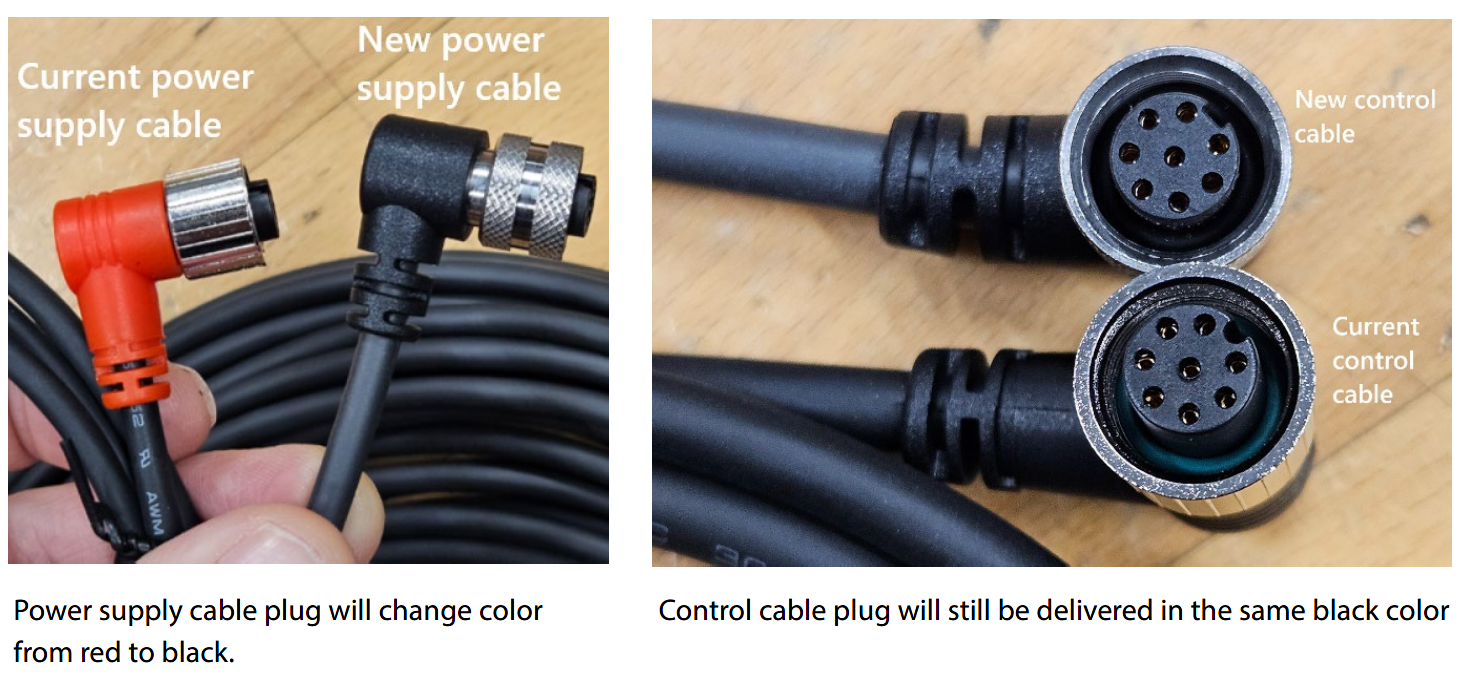

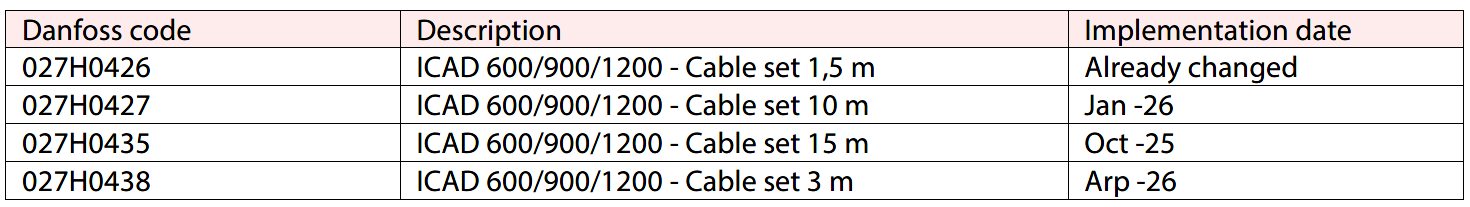

New 2x cables for ICAD actuators

2x cables which were introduced for ICAD A but now only used for ICAD B (power supply cable and control cable). Going forward these will be delivered to an improved quality with better UV resistance and stainless-steel connections. These improved cables are already used in 3x cable sets for ICAD B actuators.

Code numbers affected:

Timing

Video updates

Commercial Refrigeration

Technical literature new and updated

Commerial refrigeration/Sensing solutions

- Rotary compressors VRN

- Optyma™ Plus Controller installation V3.7

- Tube-in-tube heat exchanger - Type HE

- Electric expansion valve - ETS 5T

- Staging valve Type PTS 13L - 18L - 27L - 38P

- SH controller kit - EKE 100 1VK

- DST G200

- A2L Gas Sensor, Types DST G54B, DST GR32

- A3 Gas Sensor

- A2L Gas Sensor, Types DST G54A, DST G54C, DST G55A

- A2L Gas Sensor - Compact design DST, GSxx series

- Thermostat. Type UT

- Pressure transmitter, DST P070

- Shut-off ball valve, GBC / GBC E / GBC L

- Filter drier, shell, DCR C

Industrial refrigeration

- Optimize your cold storage brochure

- Innovative control solutions for Industrial Refrigeration eBook

- See evaporator control panels in a new light with Cool Ctrl - Advanced evaporator control panels

- User Guide | Intelligent Purging System (IPS 8) Ammonia, UL approved

- ICM and ICMTS Motorized Valves and CVE Pilot valves with ICAD Actuators

- CoolConfig ICAD Operating Manual

- Liquid level sensor - Type AKS 4100 and AKS 4100U

- Ejector controller - EKE 80

- Strainer - Type SFIA

- Evaporator control - Type EKE 450 and EKE 400

- Evaporator and room control, type EKE 400 SW Ver. 1.71

- Spare parts for - Shut-off valve, type SVA-DH 250-300 (10-12 in.)

- Motor actuator for ICM/ICM-TS motorized valves and CVE pilot valve

Food retail

- Overview brochure: ADAP-KOOL® Evaporator Controllers

- Controller for condensing unit Optyma™ Plus (SW Ver. 3.7x)

- Case/room controller (EEV), AK-CC25 Pro and AK-CC25 Pro BT

- Control panel MMIGRS2 / MMIGRS2CC

- Program. Controller, 8 relays – MCX08M2

- Control panel MMILDS

- Program. Controller, 6 relays - MCX06D

- Programming key – MMIMYK

- Program. controller, 6 relays - CSTFR1

- Program. controller, 15 relays - MCX152V

- Program. controller, 6 relays - MCX061V

- Programmable controller, 15 and 20 relays, type MCX15B2 and MCX20B2

- Pack controller, type AK-PC 782A

- Pack controller, type AK-PC 782B

- Temperature sensor, type ETN

- Case/room controller (TXV), AK-CC25 Pro

Relevant for all areas

All information, including but not limited to information regarding product selection, application or use, product design, weight, dimensions, capacity, or any other technical data of products in product manuals, catalog descriptions, advertisements, etc., whether provided in writing, verbally, electronically, online, or via download, is to be considered purely informative and is binding only if and to the extent explicitly referenced in a quotation or order confi- mation. Danfoss assumes no responsibility for possible errors in catalogs, brochures, videos, and other printed materials. Danfoss reserves the right to make changes to its products without prior notice. This also applies to products already ordered but not delivered, provided such adjustments are possible with-out substantially changing the form, suitability, or function of the product. All trademarks contained in this publication are owned by Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.