The world’s leader in oil-free compressor technology

Danfoss is the leading manufacturer of oil free compressors and is the pioneer of the Danfoss Turbocor® compressor - the world’s first oil-free magnetic bearing compressor for the HVAC industry.

Danfoss Turbocor® compressors use advanced technology to deliver high efficiency and low sound levels in a compact footprint. Industry leading performance is achieved by using oil free, magnetic bearings that provide world class efficiency and zero performance degradation over the life of the compressor. Permanent magnet motors and variable speed drives provide unmatched full and part load efficiency.

Danfoss Turbocor® oil-free centrifugal compressors have the flexibility to be used in air cooled, water cooled or evaporative cooled chillers operating in wide range of applications such as comfort cooling, low temperature process, ice storage and heat recovery. This flexibility has resulted in over 70,000 compressors installed in jobsites around the world.

Danfoss Turbocor® compressors are manufactured in Tallahassee, Florida and Shanghai, China in a ISO 9001:2015 and ISO 14001:2015 certified facility. Sales and service centers are located in the USA, Europe and Asia to serve customers around the world.

Danfoss Turbocor® technology has been recognized with awards from many prestigious organizations including the USA EPA, AHRI/ASHRAE USA, Natural Resources Canada and the Institute of Refrigeration – England.

Features and benefits

From 40 to 400 TR compressors for chillers and reversible systems

A pioneering oil-free centrifugal technology for best-in-class lifetime costs in chillers

A compact, lightweight and quiet solution

A range ready for ultra-low GWP refrigerant HFO-1234ze and R513A

ETL Listed and CE Compliant

TurboTool®

Compressor service for Danfoss Turbocor® compressors is easier than ever with the Danfoss TurboTool® App. You can troubleshoot potential issues right from your mobile phone by entering the symptoms into the app and instantly receive a list of recommendations for how to resolve the problem.

For OEM customers

Danfoss serves large HVAC chiller manufacturers (OEMs) with the Danfoss Turbocor® portfolio of compressors. With factories, sales and service located throughout the world, our distinguished OEM customers bring innovative, reliable centrifugal chiller systems with Danfoss Turbocor compressors to the HVAC market place.

Contact your OEM for Turbocor® product support. We sell our compressors to OEM chiller manufacturers only. Search below for an OEM in your region.

More chiller info?

Building chillers with Danfoss products and solutions enables you to optimize energy efficiency, reduce development time and obtain reliable performance for multiple chiller platform types and uses.

Oil-free compressors maintain consistent performance over time

Danfoss conducted a study to see how long term operation affected performance on Danfoss Turbocor® compressors. The results showed that oil-free, magnetic bearing compressors maintained consistent performance even after 10+ years of operation.

Product range

-

if (isSmallPicture) {

Turbocor® - TGS

Turbocor® - TGSDanfoss Turbocor® model TGS oil free compressors are available in 5 different models ranging from tons to 150 / 140 kW to 540kW utilizing ultra-low GWP R1234ze or R515B.

-

if (isSmallPicture) {

Turbocor® - TTS

Turbocor® - TTSDanfoss Turbocor® model TTS oil-free compressors are available in four different models ranging from 60 tons to 200 tons / 200 to 700 kW utilizing R134a or low GWP R513A.

-

if (isSmallPicture) {

Turbocor® - VTX

Turbocor® - VTXDanfoss Turbocor® model VTX oil free compressor is available with a capacity up to 450 ton / 1600 kW using R134a. This compressor is design for water and evaporative cooled chiller applications.

-

if (isSmallPicture) {

Turbocor® - TTH / TGH

Turbocor® - TTH / TGHDanfoss Turbocor® model TTH / TGH oil free compressors, optimized for high lift applications, are available in two different models utilizing R134a, non-flammable low GWP R513A (107 tons / 376 kW) and ultra-low GWP HFO1234ze (82 tons / 288kW).

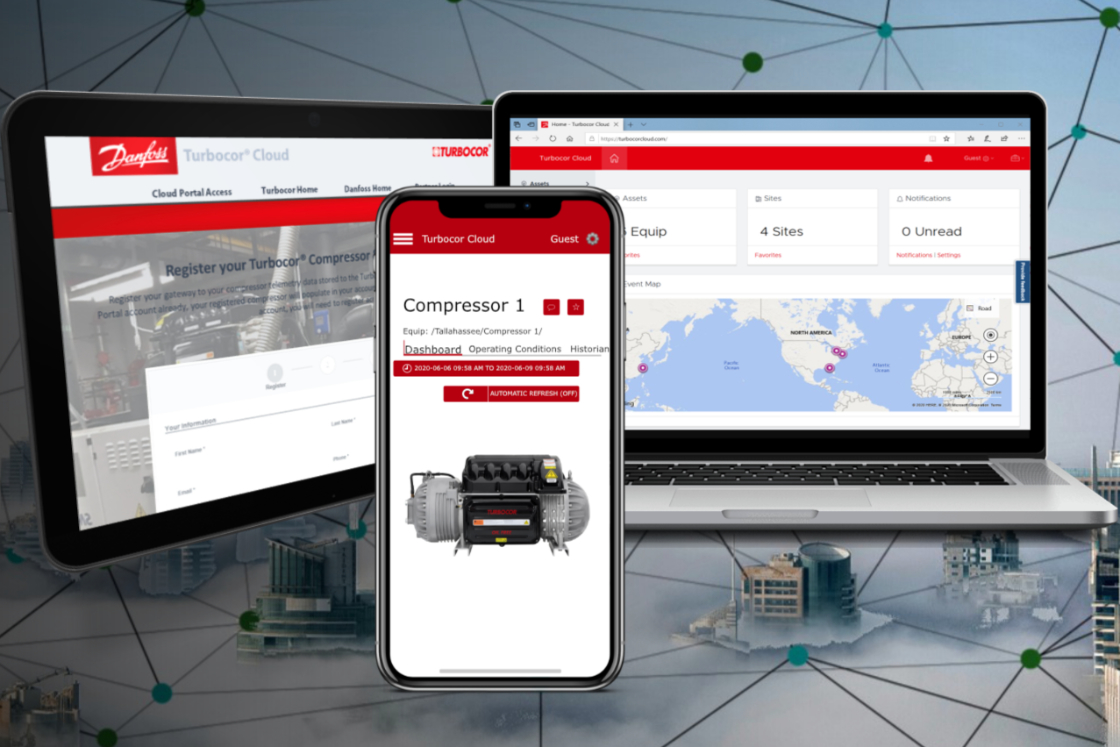

Turbocor® – Cloud Services

Danfoss Turbocor® Cloud Services is the latest connected solution from Danfoss designed specifically for Turbocor® Compressors. The cloud based service platform collects compressor information to provide powerful insight into your compressor and chiller systems performance.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Price list | 2024 Price Guide - Turbocor Compressors | English | Multiple | 16 Sep, 2024 | 1.4 MB | |

| Brochure | Danfoss Turbocor Compressor Specification Sheet | English | Multiple | 13 Aug, 2024 | 8.0 MB | |

| Brochure | Danfoss TurbocorCloud® Portal | English | Multiple | 07 Jul, 2025 | 1.7 MB |

Related solutions

-

if (isSmallPicture) {

Oil-free solutions

Oil-free solutionsToday’s HVAC systems have high demands. HVAC systems are not only required to meet energy and performance standards but also provide building owners with exceptional benefits.

Learning

Danfoss Turbocor® learning center

Danfoss offers a series of online training materials for technicians working on Danfoss Turbocor® oil-free compressors, further extending the support and learning resources to help users and OEMs maintain long-lasting performance. A series of 12 e-lessons provide a helpful overview of the unique oil-free technology, and why it's different from a conventional compressor.

The 12 new Turbocor® e-lessons are available free and on-demand through the Danfoss Learning portal.

Danfoss also offers a wide range of face-to-face Turbocor® training resources, including comprehensive two-day training events at our Tallahassee plant or on-site training for larger groups. If you require additional information, contact us at: turbocor.training@danfoss.com

Registration and contact information

- Go to the Service Training Webpage below to register for service and repair courses

- Contact our training group at turbocor.training@danfoss.com for information on courses not listed on our catalog

Case studies

-

if (isSmallPicture) {

Free-Cooling System Provides Big Returns for Schoeneck Containers

Free-Cooling System Provides Big Returns for Schoeneck ContainersFounded in 1972, Schoeneck Containers is a leading manufacturer of plastic containers for a variety of industries, including food, beverage, personal care, household and industrial products. The company’s flagship facility in New Berlin, Wisconsin, is approximately 180,000 square feet with over 30 production lines producing over 300 million containers annually.

-

if (isSmallPicture) {

NEXTDC and Smardt Chiller Group | A Quest for Perfection

NEXTDC and Smardt Chiller Group | A Quest for PerfectionA Quest for Perfection

Improving efficiency, increasing energy savings and reducing maintenance in a top-rated facility. Danfoss worked with the Smardt Chiller Group to provide leading solutions for a NEXTDC Cooling Plant in Melbourne, Australia.

-

if (isSmallPicture) {

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chiller

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chillerThe new Alsik hotel in Southern Denmark sets a higher standard in energy-efficiency and is built to reach 76% CO₂-neutrality. A main contributor is the 900-kW chillers by Clint (a company of G.I. Industrial Holding) which features award-winning Danfoss Turbocor oil-free compressors.

-

if (isSmallPicture) {

Oil-free compressors maintain consistent performance over time

Oil-free compressors maintain consistent performance over timeDanfoss conducted a study to see how long term operation affected performance on Danfoss Turbocor® compressors. The results showed that oil-free, magnetic bearing compressors maintained consistent performance even after 10+ years of operation.

-

if (isSmallPicture) {

Engineering Tomorrow solves complex energy and comfort problems for elementary school

Engineering Tomorrow solves complex energy and comfort problems for elementary schoolBuilt in 1921, A.K. Suter Elementary School in Pensacola, Florida — like many older public schools in the state — used a retrofitted patchwork of packaged and split system air conditioning equipment to keep students comfortable in a warm, humid climate. In order to rejuvenate the almost 100-year-old school, the District decided in 2011 to tear down the old school and rebuild it from scratch using new, high-efficiency HVAC technology. Today, the brand new A.K. Suter Elementary is by far the most energy-efficient of all ECSD schools – thanks in part to advanced HVAC technology, including Danfoss Turbocor® oil-free centrifugal compressors and AB-QM™ valves.

-

if (isSmallPicture) {

Oil-free centrifugal compressors: from R134a to R1234ze

Oil-free centrifugal compressors: from R134a to R1234zeThe Danfoss Turbocor® TG310 compressor is the first 60-90TR compressor introduced with R1234ze refrigerant, a refrigerant with an extremely low global warming potential.