Water and energy loss put pressure on the water industry

According to World Economic Forum 2017, a water crisis is evaluated as one of the highest risks to the world and with the largest impact.

As populations grow, pressures mount and finding a more sustainable relationship between water and energy supplies become critical in less than two decades.

Today, close to one third of the world’s population is estimated to live in water stressed and scarcity areas and by 2040, almost 20% of all countries are anticipated to experience extremely high water stress.

Yet, water and energy loss in the water sector are extremely high. In fact, the average amount of water wasted by waterworks is 40% worldwide and 26% in Europe – due to errors, leakages, and water pressure.

At the same time, 4% of global electricity is consumed by the water industry – a figure that is expected to double by 2040 – and water accounts for up to half of a municipality’s total energy bill.

Water industry challenges

Pressure control is key to reduce water and energy loss

Danfoss pressure sensors and variable speed drives are a key component for reducing water and energy loss throughout the whole water cycle.

Experiences from 112 systems in 10 different countries show that better pressure control reduces non-revenue water and unnecessary energy consumption significantly.

In average, improved pressure management leads to 38% reduction in pressure and 53% less new breaks. Among other benefits, the energy consumption is reduced by 20-40% and the typical water leakage reduction is 38%. Moreover, the improvements result in extended asset lifetime and fewer network related complaints.

Related products

-

if (isSmallPicture) {

VLT® AQUA Drive FC 202

VLT® AQUA Drive FC 202Maximum energy efficiency for both water /wastewater and Industrial pump/fan applications

-

if (isSmallPicture) {

KP / KPI, pressure switches for light industry

KP / KPI, pressure switches for light industryDanfoss KPI pressure switches are used for regulating, monitoring and alarm systems in industrial applications. The KP series are suitable for plant in connection with liquid and gaseous media.

Videos

Case studies

-

if (isSmallPicture) {

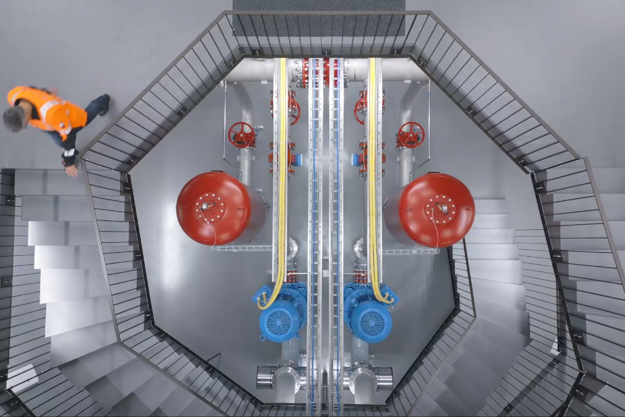

How a new water pumping station keeps supply flowing in Bern

How a new water pumping station keeps supply flowing in BernSWITZERLAND: The Wehrliau pumping station in Bern delivers up to 1.20 M liters of drinking water hourly. iC7 drives play a key role in ensuring reliable supply.

-

if (isSmallPicture) {

Keeping the Water Flowing with the VLT® AQUA Drive FC 202

Keeping the Water Flowing with the VLT® AQUA Drive FC 202In early 2023, the Warren County Utility District (WCUD) in middle Tennessee was faced with a dilemma. The water tank in their Short Mountain (SM) pressure zone required cleaning and repairs as part of federal compliance regulations, but with only one tank in the pressure zone, as is the case with many rural municipalities, they had few options to maintain water service to customers while the tank was out of service during the washout process and while repairs were completed. WCUD maintains a 4.0 MGD Water Treatment Plant, six storage tanks, four remote pump stations, into four pressure zones with approximately 650 miles of mains to serve 9,000 customers in rural portions of Warren and five adjacent counties.

-

if (isSmallPicture) {

VFD's are Secret Ingredient for Artisan Cheese Maker

VFD's are Secret Ingredient for Artisan Cheese MakerRecipes for cheese are thousands of years old, passed down through generations and crossing continents —like the Swiss cheese recipes used by Shep Ysselstein, owner and “grand fromage” of Gunn’s Hill Cheese in Woodstock, Ontario, Canada.

-

if (isSmallPicture) {

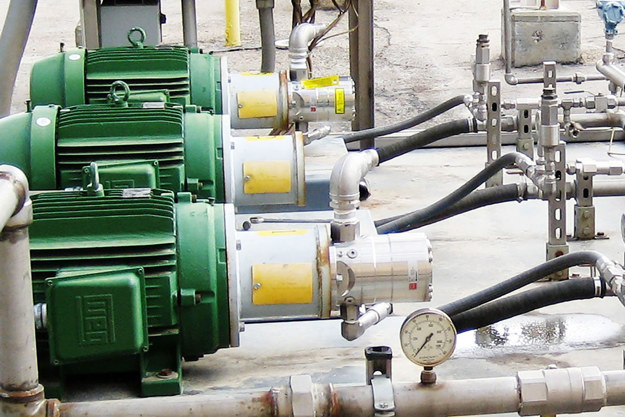

Danfoss PAHT pumps boost efficiency at California power plant

Danfoss PAHT pumps boost efficiency at California power plantDanfoss PAHT 25 pumps help to increase profitability and reduce NOx emission of a combustion turbine installed in Kingsbury, California.

-

if (isSmallPicture) {

Creating a sustainable future with seawater

Creating a sustainable future with seawaterOver the past decade, the use of Sea Water Reverse Osmosis (SWRO) for desalination has taken off. With proven efficiency rates up to 92% and energy savings of up to 65% compared to traditional solutions, the opportunities of SWRO technologies deserve further exploration.

-

if (isSmallPicture) {

Reliability and Consistency Make Danfoss VFD's a Sure Bet in Las Vegas

Reliability and Consistency Make Danfoss VFD's a Sure Bet in Las VegasFor the mechanical systems that manage the indoor environment in this desert city, consistency and simplicity are desirable traits. Owners of casino hotels and restaurants that operate around-the-clock require HVAC equipment that is reliable and easy to operate and maintain.

Contact us

For further information, please contact us.