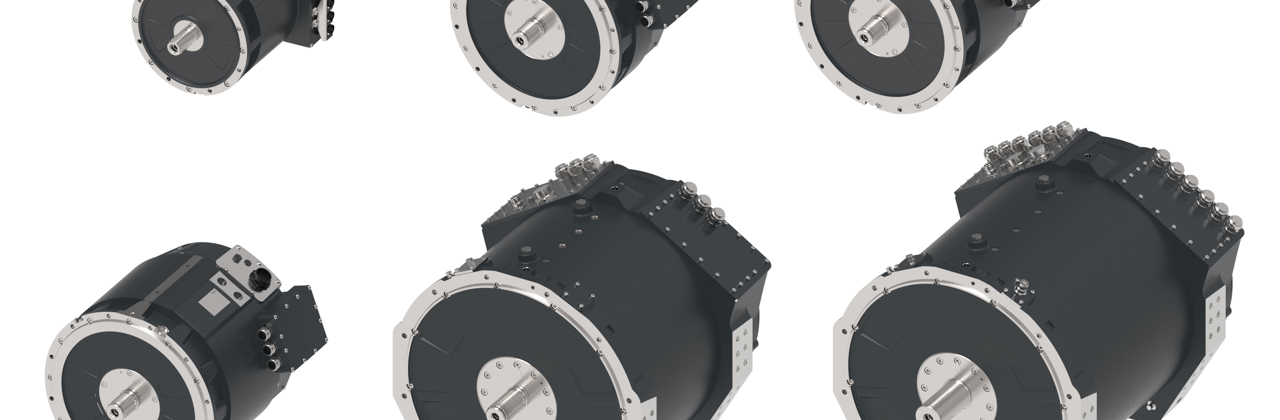

Digital Displacement pumps – improved off-highway efficiency – whichever future you choose

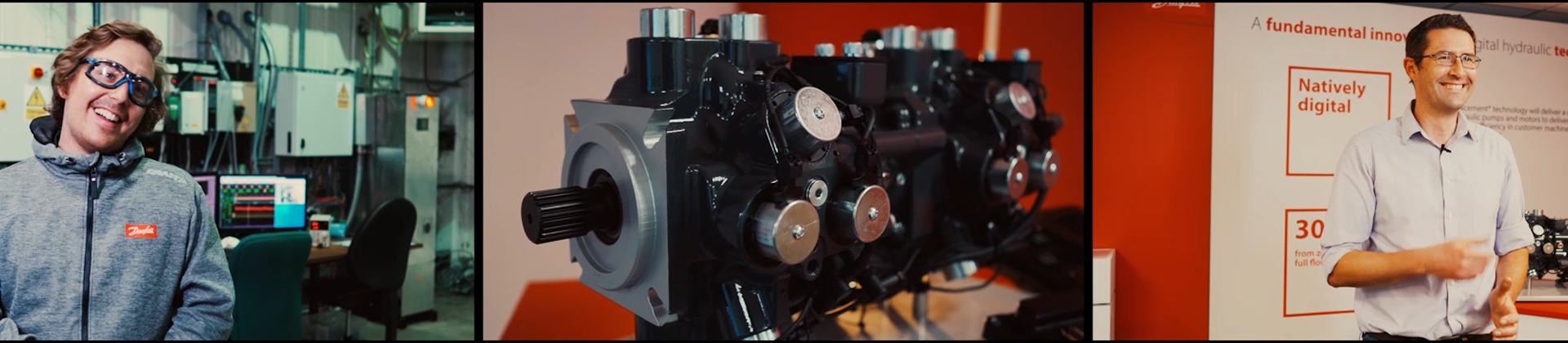

We are experts in digital mobile hydraulics

By replacing a standard pump with a digitally enabled pump, our customers enjoy improved productivity and control for better fuel consumption and the potential to downsize engines or battery packs. It is a technology which delivers benefits today and will be equally beneficial tomorrow - whichever route you take.

- Smoother faster control means more work done per day

- Improved engine-to-work efficiency means increased maximum power - with the same size engine. Or the opportunity to downsize engines, without any loss of power or control

- Intelligent digital controls mean individual cylinders are only called into action when required, reducing losses system-wide

- This means longer work-cycles or smaller batteries for next-generation electric machines

Digital Displacement® Innovation center

Each Danfoss Digital Displacement pump will be assembled at our new global Digital Displacement manufacturing and R&D facility near Edinburgh, Scotland.

Here we have developed a ground-breaking, dynamic manufacturing facility which brings a new approach to precision assembly. This will ensure quality at every stage.

The fully flexible facility has been custom designed from the ground up. Helping to assemble a new generation of Digital Displacement pumps for off-highway and industrial customers.

Production has already begun, with the first customer pumps rolling off the line in August.

News

-

if (isSmallPicture) {

Greater hydraulic efficiency can reduce excavator battery requirements by 24.8%Thursday, December 15, 2022

Greater hydraulic efficiency can reduce excavator battery requirements by 24.8%Thursday, December 15, 2022New research published by Danfoss Power Solutions shows that combining an electric motor with a Digital Displacement® pump in an excavator is the most efficient way to turn battery energy into hydraulic work.

-

if (isSmallPicture) {

UK government awards grant to Danfoss Power Solutions to decarbonize construction machineryThursday, October 13, 2022

UK government awards grant to Danfoss Power Solutions to decarbonize construction machineryThursday, October 13, 2022Danfoss plans to make electric off-road vehicles cheaper to own and run than diesel equivalents. New Danfoss Power Solutions facility in U.K. will be a global technology center and manufacturing site

-

if (isSmallPicture) {

Danfoss Digital Displacement pump awarded top honors in Diesel Progress Summit AwardsFriday, October 7, 2022

Danfoss Digital Displacement pump awarded top honors in Diesel Progress Summit AwardsFriday, October 7, 2022Danfoss Power Solutions’ Digital Displacement® pump received two awards at the Diesel Progress Summit Awards, including Achievement of the Year, the program’s highest honor. The pump was also named the Powertrain Product of the Year. The award program, now in its fourth year, is organized by Diesel Progress magazine and KHL Group and held in conjunction with the Diesel Progress Summit, a conference for the global engine and powertrain technology industry.

Support

For more information, please contact our Power Solutions digital displacement team.

Documents

Related products

Case studies

-

if (isSmallPicture) {

Creating a future of fast charging electric vehicles

Creating a future of fast charging electric vehiclesDiscover how Danfoss, in partnership with PowerFlex, helped InMotion solve fluid conveyance challenges in an all-electric, ultra-fast charging prototype race car

-

if (isSmallPicture) {

Improving marine winter navigation

Improving marine winter navigationThe Winter Navigation Motorway of the Sea II (WINMOS II) project, co-funded by the EU Connecting Europe Facility Programme, was a €7.6 million scheme aimed at developing and enhancing the maritime winter navigation system in the EU’s northernmost waters, such as the Baltic Sea.

-

if (isSmallPicture) {

ZPMC straddle carriers case story

ZPMC straddle carriers case storyThe electrification and automation of ports are receiving significant attention globally, with the majority of the largest ports in the world preparing or already implementing ambitious programs.

-

if (isSmallPicture) {

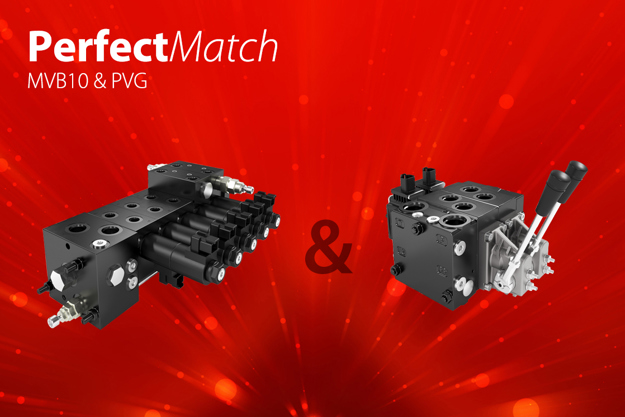

Perfect Match – MVB10 and PVG

Perfect Match – MVB10 and PVGThe combination of MVB10 Modular Valve Block with PVG16 and PVG32 valves gives you the tailor-made solutions that can match the increasing demands within the hydraulic controls market. The MVB10 is a modular system that enables you to create flexible hydraulic control solutions with standard components, ensuring the best speed to market is achieved with a high-quality product tailored to machine requirements.

-

if (isSmallPicture) {

Kovaco Electric MiniZ

Kovaco Electric MiniZEuropean manufacturer Kovaco has a strong track record of developing products that push the limits of technology, efficiency and environmental performance. The company’s Kovaco Electric division provides sustainable solutions for the future, offering environmentally-friendly and cost-efficient products with high safety levels.

-

if (isSmallPicture) {

3ME Technology removing diesel and improving safety in underground mining

3ME Technology removing diesel and improving safety in underground miningThe mining industry is increasingly turning to commercial vehicle electrification solutions for the machinery used during operations because of the performance and safety benefits they offer

Contact us

My Digital Displacement story

Stay up-to-date with the latest developments on our projects and the wider industry, read stories from our engineering experts and watch videos of our team revealing their Digital Displacement stories.