The construction and operation of a district heating facility is a complex task: In particular, countless controllers, which are often also widely distributed throughout the network, must be monitored. Danfoss now makes this easy with Leanheat® Monitor, a newly developed SCADA software system that visually depicts all components, collects their data and monitors their functioning. The system also ensures that the data is used profitably – to increase plant efficiency, to improve condition monitoring, or to streamline billing processes, for example.

St. Lambrecht is a municipality with just under 1,900 residents in the district of Murau in Styria, Austria. It is well known throughout the country mainly for the Benedictine monastery (St. Lambrecht’s Abbey) that was founded there in 1076. At the beginning of the 1990s, the municipality commissioned a feasibility study for a district heating plant. This study predicted a very positive outcome if such a plant were to be built, as it would generate benefits in the form of high efficiency, maximum economy, and low maintenance requirements. In addition to these advantages, the design of district heating plants makes them safer than conventional heating systems. Unlike the case with a central heating boiler, for example, district heating systems don’t require an open flame in the home, which reduces the risk of fire. The danger of gas leaks is also eliminated because district heating systems don’t use gas lines. Given all these advantages, the municipality decided to build the plant, with construction beginning in 1992. Today, the maximum configuration specified in the study has nearly been attained. The St. Lambrecht Heating Supply Association now supplies district heating to a total of around 150 customers that include the Benedictine monastery, the local elementary and secondary school, and the explosives manufacturer Austin Powder (known until 2003 as Dynamit Nobel Wien). These are among the largest customers; the rest are mainly private households and hotels. Most customers also use district heating for hot water.

The region benefits

“We are a farming cooperative in which 14 farmers and the Abbey hold shares that are linked to a proportionate wood supply right,” explains Florian Wallner from the St. Lambrecht Heating Supply Association. “This means that the biomass and thus the heat is generated directly in the region.” Short transport distances help protect the environment – and that fact naturally contributes to the good overall energy balance, as do the relatively low fuel costs and the very high security of supply. The benefits go beyond these aspects, however. “The district heating plant creates jobs, and regional commercial enterprises also benefit,” says Wallner. Two boilers are installed in the biomass heating plant: The first, with a combustion capacity of 1 MW, dates back to the early days of the plant and was commissioned in 1993. The second and more powerful boiler (2.2 MW) was installed in 2008.

Networked technology

Danfoss has been a partner of the St. Lambrecht Heating Supply Association for quite some time. Various Danfoss products are used by the association, including ball valves and three-way valves in the heating plant and in the district heating pipes, as well as the district heating transfer stations at the individual consumers, which hydraulically separate the primary system from the secondary system. Danfoss control components, which also control the individual heating circuits at the customers, are installed here. All of these products have one thing in common: Solid technology that also meets all of today’s networking requirements. “Connection to the Internet is a standard feature of Danfoss controllers,” says Norbert Spreitzer from Technical Support Heating at Danfoss. “Customers can have their controller visualized via an app on their smartphone or tablet and also operate it remotely – all at no additional cost.” An interesting additional feature for many end customers is that data is transmitted using encrypted protocols as a matter of course.

Software as an all-round talent

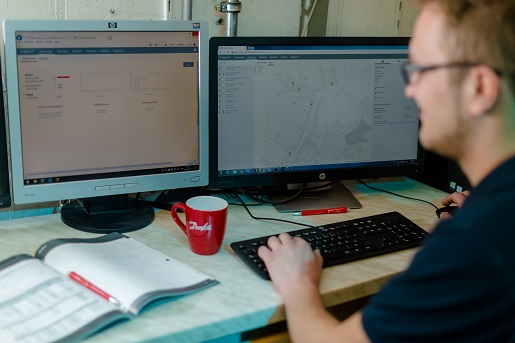

All of this data is of course also available to the operator at the district heating plant, where it is combined to form a larger whole. In order to make this data consolidation possible, Danfoss developed its brand-new Leanheat® Monitor software specifically for district heating systems. “Leanheat® Monitor is a web-based SCADA software system, which offers an advantage in that it can be accessed with any standard browser on both stationary and mobile devices,” says Spreitzer. Leanheat® Monitor visualizes all plant components, collects data, and records and evaluates it. What sounds simple at first actually gets much more complicated, which of course increases the benefits. Leanheat® Monitor performs other tasks in addition to visualization. For example, the parameter settings in the controllers can be adjusted and monitored remotely. The actual values, setpoints, and historical values of all temperature sensors and heat meters connected to the controllers are checked and recorded. It’s easy to maintain a clear overview of all these aspects – the software engineers at Danfoss have truly done a great job. A function monitoring system is also included. This system sends an alarm (usually by email) if a controller fails or the temperature drops below a specified setpoint in a certain area. The settings for these alarms can be defined by both the operator and (to a lesser extent) by the end customer as required. Leanheat® Monitor makes predictive plant maintenance possible, as changing data often indicates imminent damage, and with its connection to the alarm system, Leanheat® Monitor makes it possible to repair or replace a component before it fails completely. “In other words, you no longer have to wait for the angry call from the customer; instead you can intervene preventively beforehand,” Spreitzer explains.

Finding available capacities

The benefits for customers go far beyond all of this. “The data from Leanheat® Monitor can be used to optimize the efficiency of the plant,” says Spreitzer. Unusually high levels of consumption can be detected, which means end customers can be given advice by the plant operator on matters of energy efficiency. This is a highly useful additional feature, especially for the St. Lambrecht Heating Supply Association, aas they soon will reach their maximum configuration. With Leanheat® Monitor new capacities are released and additional customers can easily be connected to the district heating network. And what better way to ferret out capacities than by using software that displays the entire network and all associated data in great detail? All of this can be summarized as “optimization of the district heating network.”

Open data usage

Although St. Lambrecht supplies around 150 district heating customers, the number of customers is not a decisive factor in terms of the use of the software, as it’s profitable from the very first customer. There are also no upper limits – Leanheat® Monitor adapts its functional scope optimally to both small and large customers. The advantage here is that all Danfoss controllers are compatible with Leanheat® Monitor. Speaking of profitable: Of course, district heating has to be paid for, even if it is a very cost-efficient energy source. In this regard, Leanheat® Monitor also pays off in that consumption data can be directly used for billing processes. The invoicing process for the plant operator is thus incredibly simple. “Cooperation with Danfoss is smooth and uncomplicated in every respect,” is how Florian Wallner describes his experience over the last few years. This especially applies to employees, who are always ready to

listen to their customers and offer them help and advice. Then there are the products, of course, which display outstanding performance. “The whole package just fits. Danfoss offers a state-of-the-art solution, while at the same time pointing the way toward the future, for which we are now well prepared.” Moreover, Danfoss’ developers and engineers already have other useful ideas for this future: For example, the idea of using Leanheat® Monitor with products from manufacturers other than Danfoss is being considered, which would make the visualization of district heating plants even clearer and more effective.