BelOrta is the largest cooperative auction in Europe in the field of fruit, vegetables and organic products. The company sites are centrally located in the 'garden of Europe'. The fruit and vegetable sector is a dynamic market, in which it is necessary to be able to quickly switch between different levels. From the macro level, where one needs to take into account global trends such as the recent sanctions against Russia to the micro level, where the company's locations must be able to handle peak loads and process thousands of tons of fruit.

Eco policy

BelOrta's operational strategy is as green as the apples and pears stored in the cold stores of the auction sites. The BelOrta organisation has already achieved ambitious goals in the field of cooling. The company recently achieved a CO₂ reduction of 100%. This ambitious attempt to increase cooling efficiency is fully in line with our Eco policy, according to Yves Souvereyns, Cooling Supervisor at BelOrta. It is important to recognize that a 'green' strategy will only succeed if it is integrated in the total fruit processing distribution chain. Facilitating processes such as cooling are also important part of this integrated whole. The improvements would therefore not have been possible without the expertise of AB Coolservice and Danfoss. AB Coolservice played an active part (from initial design to realisation) in the most recent refrigeration project, namely in helping to increase the flexibility of the refrigeration systems at the Fernelmont location. Mainly apples and pears are cooled at this location. Bart Aerts, Managing Director at AB Coolservice: 'Our corporate philosophy is based on innovation. We provide customised solutions integrating energy efficiency and green solutions to customers with complex cooling issues. Together with our partner Danfoss, producer in the field of industrial Cooling components such as valves and controls, we rose to the challenge at BelOrta'. 'The company philosophy of the Danish company fits this project like a glove: Like AB Coolservice, Danfoss is a proactive and leading company in terms of phasing out environmentally harmful refrigerants' (phasing out is central to F-Gas Regulations: European legislation that mandates the use of more environmentally friendly refrigerants and strongly recommends a further reduction of CO₂ emissions), explains Bruno Yperman, Industrial Cooling Sales Engineer at Danfoss. The refrigeration components and controls were an important part of the success of the project to increase flexibility.

'We achieved a CO₂ emission reduction of 100% with the conversion of the plant.'

- Bart Aerts, Managing Director at AB Coolservice

The project

In broad terms, the refrigeration project was based on two objectives: [1] the reduction of CO₂ emissions – and therefore a greener refrigeration system – and [2] increasing the flexibility of the cooling process. In practice, this meant the conversion of the existing installation for the refrigerant R507A to one for the refrigerant R717 (Ammonia). R507A is a synthetic refrigerant and is also known as HFC (hydro fluorocarbon). HFCs are one of the main sources of greenhouse gas emissions. R717 (or ammonia), however, produces no CO₂ emissions. Making the process more flexible meant the conversion of fifteen larger cold stores into thirty smaller stores and one transit area. The cooling capacity is thus divided across smaller zones. This reduces excess refrigeration capacity, which ultimately benefits overall energy consumption. This will eventually lead to a lower energy consumption. Another important element of the flexibility process is the ability to stock products other than apples and pears. The updated refrigeration systems can also keep the products at a temperature of −2°C. This allows products such as chicory, strawberry and blackberry plants to be stored in the cold stores.

'The field of precision cooling requires not only knowledge of components, but also deep industry expertise, in order to meet the strict requirements in the food industry.'

- Bruno Yperman, Industrial Cooling Sales Engineer at Danfoss

![Three refrigeration experts [from left to right: Bruno Yperman, Danfoss; Yves Souvereyns, BelOrta; Bart Aerts, AB Coolservice]](/media/3768/sowing-ammonia-reaping-energy-efficiency-4.jpg)

Three refrigeration experts [from left to right: Bruno Yperman, Danfoss; Yves Souvereyns, BelOrta; Bart Aerts, AB Coolservice]

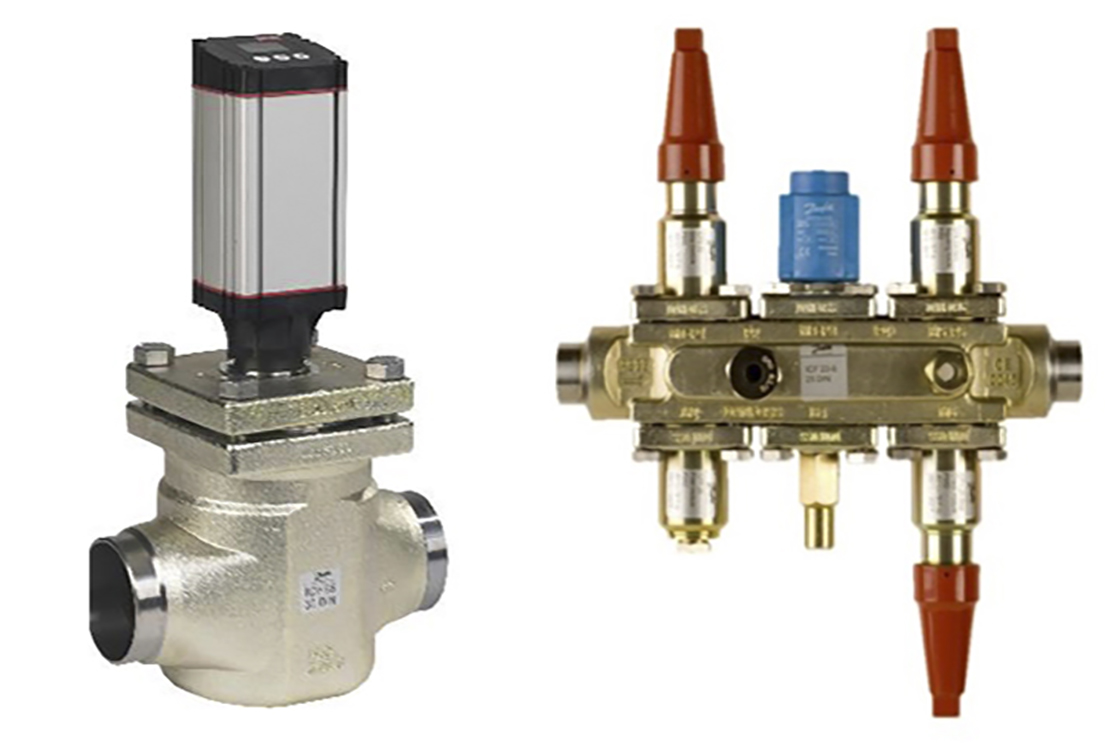

Yves: 'Cooling down and storing fruit is a very precise and delicate process. The core temperature of the fruit must be reduced to 0°C during cooling and then further reduced to a storage temperature of −1°C. During the cooling process, the temperature of the fruit must be adjusted up to one tenth of a degree (°C).' Bruno: 'Our products play an important part in this process. Using a combination of ICF (valve station) and ICM (valve with neutral zone control), we can adjust and monitor the temperature very precisely. These components allow us to greatly increase the cooling capacity of the evaporator when cooling the fruit (down to 0°C). With long storage, there is also the advantage that we can work with a minimal pressure drop in the suction line (which benefits efficiency), and that the temperature can be very accurately controlled'.

30 cold stores were built under the flexibility project in Fernelmont; the cooling capacity per store is 133 tonnes of apples or 166 tonnes of pears.

The result

Bart Aerts: 'AB Coolservice has extensive experience of standard and complex industrial Cooling issues. We have years of expertise in a range of sectors where cooling is subject to very strict requirements. In addition to the food industry and other sectors, we are also active in the pharmaceutical industry and laboratories (where we build cleanrooms). This experience is what allowed us to provide BelOrta with tailored advice in this project and deliver the right solution. The end result has definitely been a success. The conversion of the cooling systems has really made a difference: if we look at the GWP of the refrigerant, we managed to reduce CO₂ emissions from 5977.5 tons to zero'.

Yves concludes: 'With the cooling process, too, we managed to contribute towards BelOrta's eco policy. We are now assured of a 'green' cooling process. However, this doesn't mean that our work is done here. We will continue to push the boundaries in terms of energy efficiency and CO₂ emissions, when it comes to refrigeration. I enjoy working on these goals together with partners like AB Coolservice and Danfoss.'

![‘In our industry, you literally reap what you sow. We have managed to significantly reduce our CO2 footprint with the support and expertise of suppliers like AB Coolservice and Danfoss.’ [Yves Souvereyns, Cooling Supervisor at BelOrta]](/media/3770/sowing-ammonia-reaping-energy-efficiency-2.jpg)

'In our industry, you literally reap what you sow. We have managed to significantly reduce our CO₂ footprint with the support and expertise of suppliers like AB Coolservice and Danfoss.'

- Yves Souvereyns, Cooling Supervisor at BelOrta

Yves concludes: 'With the cooling process, too, we managed to contribute towards BelOrta's eco policy. We are now assured of a 'green' cooling process. However, this doesn't mean that our work is done here. We will continue to push the boundaries in terms of energy efficiency and CO₂ emissions, when it comes to refrigeration. I enjoy working on these goals together with partners like AB Coolservice and Danfoss.'

Danfoss's ICM and ICF components are crucial for precision temperature control