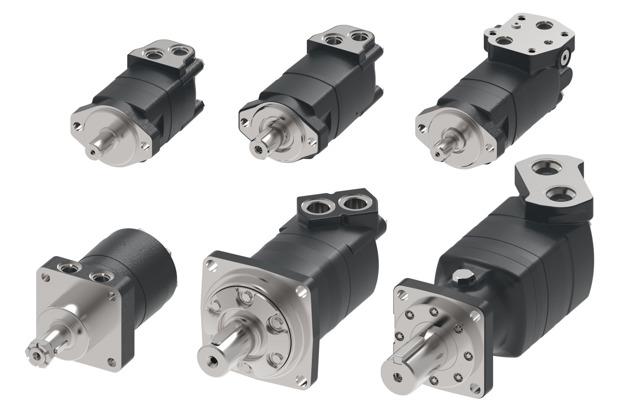

TMT/TMV/TMK series, for tough applications

With pressure capability up to 350 bar [5,080 psi] and high starting torque, the TMT/TMV/TMK series is the energy-efficient choice for the toughest working environments.

Leading performance with a long lifetime makes light work of the heaviest duties. Up against high pressures, thin oil or frequent reversals, our motors are guaranteed to perform smoothly and efficiently - even at low speed.

TMT/TMV/TMK series characteristics

Motors with speed sensor

Ultra short motors

Motors with integrated brake

Motors with integrated flushing valve

Special dust seal ring for additional shaft seal protection

Features and benefits

High bearing capacity and robust cardan shaft design for longer life

Outstanding motor efficiency for reduced fuel consumption

Low leakage, securing energy savings

Short motors without bearings for compact integration in gear boxes and other flexible design options

Integrated flushing valve for continuous oil renewal and cooling in a closed circuit

Special mounting flange on wheel motors for optimal utilization of bearing capacity

Product range

Our large orbital motors are an excellent choice for the propel and work functions on many applications – including skid steer loaders, trench compactors, forestry harvester heads, and beet harvesters.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| User guide | TMK/TMKW/TMK FL Orbital Motors Technical Information | English | Multiple | 09 Mar, 2015 | 3.9 MB | |

| User guide | TMT TMTU TMTW TMT FL Orbital Motors Technical Information | Japanese | Japan | 27 Nov, 2024 | 10.9 MB | |

| User guide | TMT TMTU TMTW TMT FL Orbital Motors Technical Information | English | Multiple | 09 Mar, 2015 | 7.7 MB | |

| Data sheet | TMTHW Orbital Motor Data Sheet | English | Multiple | 10 Mar, 2015 | 500.7 KB | |

| User guide | TMTHW Orbital Motor Technical Information Manual | English | Multiple | 10 Mar, 2015 | 1.3 MB | |

| User guide | TMVW Orbital motor Technical Information Manual | English | Multiple | 09 Mar, 2015 | 1.6 MB |

Related products

-

if (isSmallPicture) {

OMT/OMV series

OMT/OMV seriesThe OMT/OMV-series is our flexible choice. Delivering premium power for large motors, medium to heavy-duty needs with pressure capability up to 275 bar (3,990 psi). Robust, reliable and designed with passion to care for our customers needs.

-

if (isSmallPicture) {

2000, Delta, 4000, 4000 Compact, 6000, 10 000 Series

2000, Delta, 4000, 4000 Compact, 6000, 10 000 SeriesBuilt for tough jobs, Danfoss char-lynn disc valve motors allow higher flows and pressures than spool valve motors.

-

if (isSmallPicture) {

J, H, S, T series

J, H, S, T seriesSmall but powerful, Danfoss Char-Lynn low-pressure spool valve motors are perfect for general purpose applications, from harvesting equipment to food processing plants. They provide reliable, continuous operation in demanding environments.

-

if (isSmallPicture) {

Track and swing motors

Track and swing motorsApplication specific track and swing drive motors.With industry leading geroler® design, these orbital motors secures excellent efficiency, two speed and low slip performance designed for mini-excavators

-

if (isSmallPicture) {

Speed sensors

Speed sensorsSpeed sensors for orbital motors, LSHT motors and hydraulic motors. EMD speed sensor

PowerSource

Visit PowerSource

Visit PowerSource to view product specifications, literature and helpful tools like product configurators, 2D/3D models, and more.