Although just one percent of worldwide water consumption currently derives from desalinated seawater, desalination is responsible for an outsized share of water treatment’s global energy usage.

One percent doesn’t sound like much, but more than 300 million people in 174 countries already rely on desalination, and even more will in the future. Forecasts point to strong growth for the global desalination market, with an expected CAGR of 9.5% for 2020 – 2025 and similar rates for the foreseeable future after that.

Until now, thirsty populations have been willing to pay the costs of desalination’s disproportionate energy intensity because the alternatives are worse – either going without potable water or water transfer from regions with abundant water to regions with too little. But as these energy and greenhouse gas (GHG) costs grow in step with the world population’s increasing dependence on desalination, there must be further focus on maximizing desalination’s energy efficiency and decreasing its carbon footprint.

Retrofitting the installed base will play a significant role in making desalination greener.

Desalination has already come a long way in reducing energy consumption, but more is necessary

As we described in our last blog, A Brief History of the Energy Intensity of Desalination, a lot has happened during the almost 100 years that desalination has taken place at scale. Nearly 22,000 desalination plants have been built worldwide, and they have become increasingly energy efficient over time. First-generation desalination plants using thermal distillation, some of which are still in operation today, require as much as 27 kWh/m3 to produce potable water. This is more than 14 times as much energy and related GHG emissions as the current state of the art, high-efficiency SWRO plants that need less than 2 kWh/m3.

Most SWRO plants installed in the last 15 years or so utilize isobaric ERDs, which reduce the plant’s SEC by 35% on average. However, much of the installed base continues to rely on technology that is far less energy-efficient than best-in-class alternatives.

The promise and challenges of retrofitting

The huge range in specific energy consumption across so many installed plants begs a simple question: Why not retrofit plants with the least energy-efficient desalination technology with the most energy-efficient available? The answer comes down to cost-benefit analyses – or the lack thereof.

The benefits of retrofitting energy-inefficient desalination plants are clear: reduced OPEX and GHG emissions. Some of the expenses, e.g., CAPEX, are equally transparent – while other costs are not. Take GHG emissions and carbon pricing, for example. McKinsey estimates that 40% of the world’s potential to reduce GHG can be realized at a cost of less than €60 per metric ton of carbon dioxide equivalent. However, as long as the full costs of GHGs, for example, in the form of uniform carbon taxes at realistic levels, are not factored into the financial costs of energy, the incentives to choose the most efficient energy solutions are not significant enough for many to act on.

Other barriers to retrofitting have to do with the reliability of energy-savings and payback time projections and understanding hidden and total retrofit costs. We’ll explore these and other issues involved with retrofitting desalination plants in later blogs. For now, we want to develop an estimate of how energy-efficient desalination could be if all plants operated at what we now consider to be maximum efficiency.

The total, worldwide potential energy and CO₂ saving if existing desalination plants were retrofitted to become as energy-efficient as possible

To estimate the potential savings, we had to make a number of assumptions and calculations.

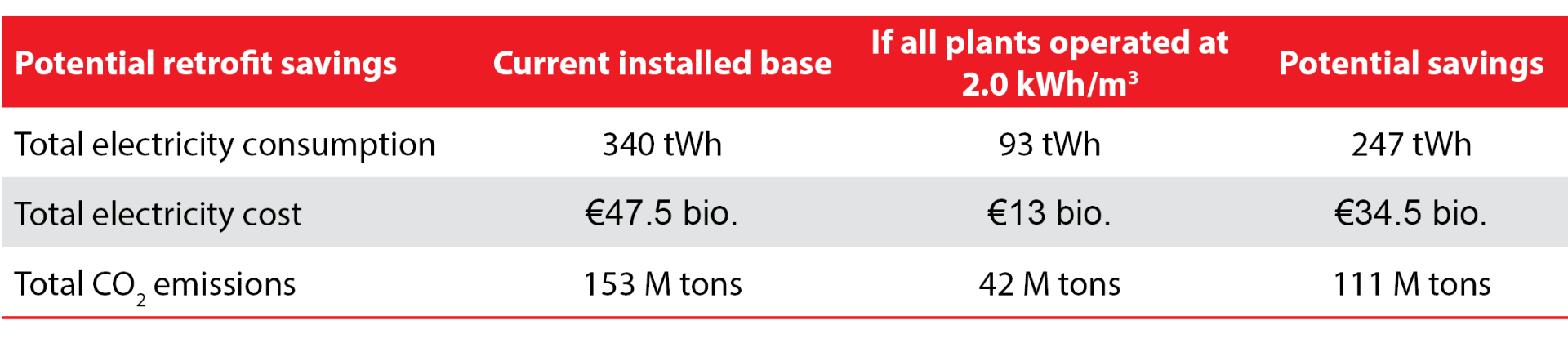

First, we calculated the current energy consumption, cost, and related CO₂ emissions of the installed base of desalination plants worldwide. These totaled 21,755 plants with a combined capacity of 128 million m3/d.

Then, we calculated the energy consumption, cost, and related CO₂ emissions of the installed base of desalination plants worldwide – if all plants operated with a specific energy consumption of 2.0 kWh/m3, the current “state of the art” for high-efficiency SWRO plants.

Assumptions:

- Electricity cost: We used €0.14/kWh for all plants, an average based on global rates. Of course, actual electricity costs vary considerably across the installed base, and are much higher in some locations.

- CO₂ emissions: CO₂ emissions from electricity generation depend on how the electricity was generated. For this estimate, we used the U.S. Energy Information Administration’s average for all electricity generated in the United States in 2019, 0.92 pounds (453g) per kWh.

As the table above shows, the potential energy, financial and GHG savings are huge.

To put these potential savings in perspective:

- 247 tWh of electricity is more than all of Spain used in 2020, 228 tWh.

- €34.5 billion would build about seven windfarms the size of Hornsea Project 1, the world’s largest, and provide electricity for approximately seven million homes.

- 111 metric tons of CO₂ emissions is greater than Bangladesh’s 163 million people produce yearly, 102 metric tons.

Of course, we cannot use these calculations to argue for retrofitting the entire installed base of almost 22,000 plants with the most energy-efficient alternative. The cost-benefit analysis and payback time would vary case by case.

We do believe, however, that this exercise is helpful in framing the enormous potential of retrofits to improve energy efficiency, reduce operating costs, and make desalination part of the solution to meet climate goals – not just a part of the problem.

Related blogs

Read more about our solutions for desalination

-

if (isSmallPicture) {

High-pressure pumps for SWRO applications

High-pressure pumps for SWRO applicationsThe range of high-pressure APP pumps is optimized for both landbased, off-shore and marine sea water reverse osmosis applications. Available with or without motor.

-

if (isSmallPicture) {

Energy recovery device for medium to large SWRO applications

Energy recovery device for medium to large SWRO applicationsThe first active ERD for medium and large plants integrates highly effective isobaric pressure exchangers with a low-voltage motor to eliminate the risk of rotor overspin, reduce mixing and biofouling, and facilitate smarter automation. Covering train sizes from 1,500 m3/day and above.

-

if (isSmallPicture) {

iSave® energy recovery devices for high-pressure membrane applications

iSave® energy recovery devices for high-pressure membrane applicationsWith a 3-in-1 design that integrates highly effective isobaric pressure exchangers with positive displacement booster pumps and electrical motors, iSave® ERDs deliver big energy savings in small spaces. Covering train sizes from 200-3,000 m3/day

-

if (isSmallPicture) {

VLT® AQUA Drive FC 202

VLT® AQUA Drive FC 202VLT® AQUA Drive FC 202 controls all types of pumps and comes equipped with a cascade controller.

-

if (isSmallPicture) {

DST P40I titanium pressure transmitter for use in corrosive environments and with aggressive media

DST P40I titanium pressure transmitter for use in corrosive environments and with aggressive mediaFor use in corrosive environments and with aggressive media, Danfoss offers the robust DST P40I pressure transmitter made of Titanium and with ceramic pressure sensing element. DST P40I is optimized for use in applications such as desalination systems, seawater cooling, and chemical processing.