Your go-to newsletter for technical updates and latest changes in refrigeration and industrial solutions—delivered nearly every month.

Danfoss Tech Insider keeps you up to date with the latest developments in the Cooling and Industrial Products portfolios from Danfoss Climate Solutions. Each edition ofers a quick overview of key technical updates and product news, with direct links to relevant documentation and further details. Published monthly, Tech Insider ensures you’re always informed about the latest innovations and changes across our products and solutions. We hope you enjoy reading Danfoss Tech Insider and find it both useful and inspiing!

Table of contents

- Release of Danfoss NeoCharge Solution

- Introduction of a new magnetic coupling seal in motor-operated ICM and ICMTS valves, CVE pilot valves, and ICF valve stations

- AK-SM 800A series, software release 4.3.1 including security updates

- StoreView Web (SvW) release 3.4.1

- PSG scroll compressor for industrial process heat-pumps R600a/R134ze - Refined design

- MTZ 4-cyl compressors qualified with R454A/C and R455A

- PSH039A4 50Hz VI envelope extension

- New models released for MLZ/LLZ evolution C with refrigerant R454A, R455A, R455C

- Important information regarding NTZ096-4 compressor and R454C refrigerant

- ETS 5M valve and coil redesign

- New and updated Technical literature

Commercial Refrigeration

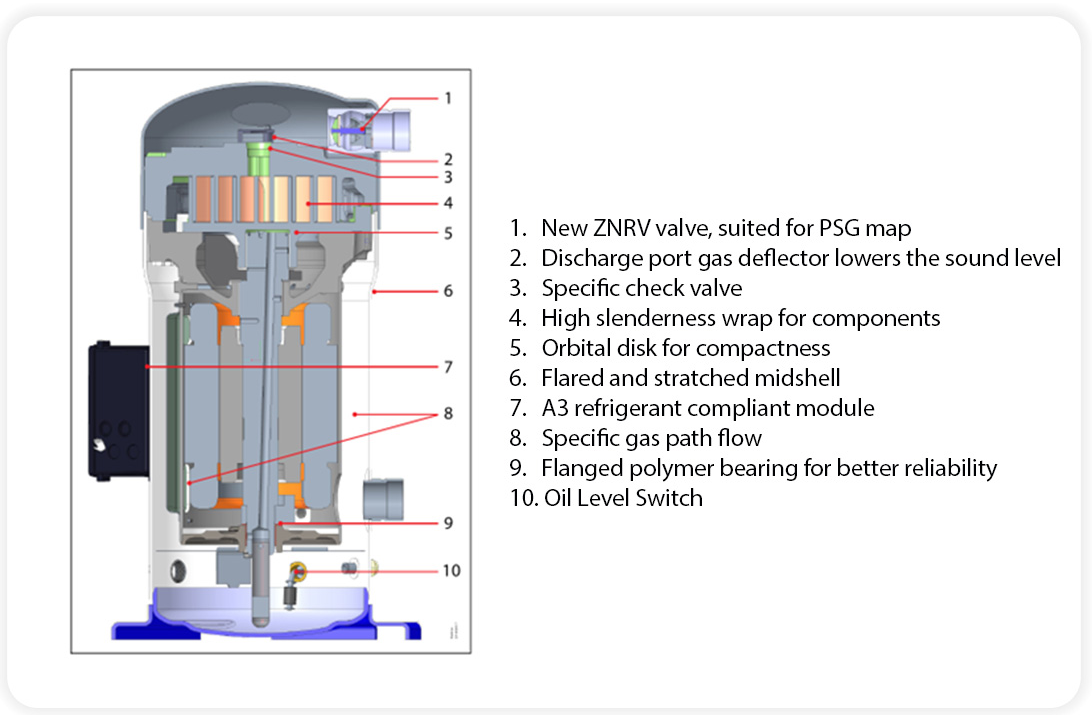

The PSG compressor is a high temperature scroll compressor specifically optimied for W/W High Temperature Heat Pump applications ranging from 100 kW to 1 MW. It is primarily qualified with lw-GWP refrigerants such as R-1234ze (A2L), R-515B (A1), and R-600a (A3), which opens new possibilities for heat pump and booster systems that need to supply hot water up to 100°C. The compressor’s design has been refined o accommodate the standard source temperatures available in processes (10-40°C), ensuring efficit operation in W/W units, whether as a single stage or potentially as a second stage in a multistage system.

The PSG family includes two models: the PSG605 and PSG800, delivering 105 m³/h and 140 m³/h respectively at 50 Hz. Both compressors are compatible with a variety of manifold solutions, from tandem (both even and uneven) to even trios, providing maximum flxibility in creating potential unit lineups.

Additionally, a new generation of Oil Level Switch is integrated directly into the compressor, mitigating reliabilityrisks associated with temporary oil shortages.

Cut Away PSG605-800

We are excited to announce an important update regarding our MTZ compressor models. These models are now approved for use with the refrigerants R454A/C and R455A, which can replace R404A and R507 in their applications.

The refrigeration industry has made significat progress in reducing the use of ozone-depleting refrigerants. A new trend of using synthetic refrigerants is emerging, driven by the global agenda on climate change and global warming. Synthetic refrigerants, particularly those with low Global Warming Potential (GWP), will play a crucial role in the industry.

Danfoss is committed to supporting the development and application of these refrigerants, enabling our customers to achieve low GWP goals while enhancing energy efficiey.

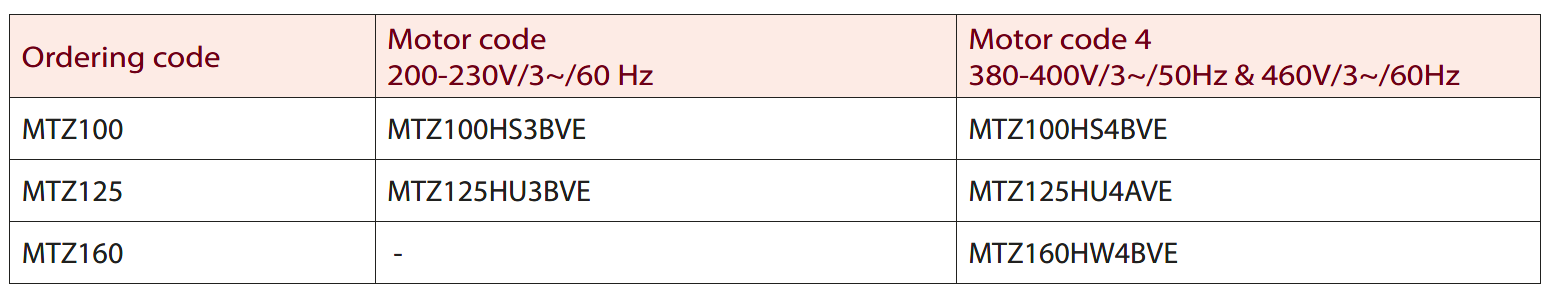

The MTZ models listed below are qualified or use with refrigerants R454A/C and R455A, classified in efrigerant Group 1. R454A has a GWP of 238, while R454C and R455A have a GWP below 150. These refrigerants are classified as A2L, indicting low flammabiliy properties. Please refer to European regulations (EN378, EN60335) and EPA rulings in the US for safe use. Outside of Europe and the USA, consult local regulations.

The following compressor models are qualified or use with R454A/C and R455A

This change will be implemented in July 2025. All compressor models listed above are qualified with R454A/C and R455A

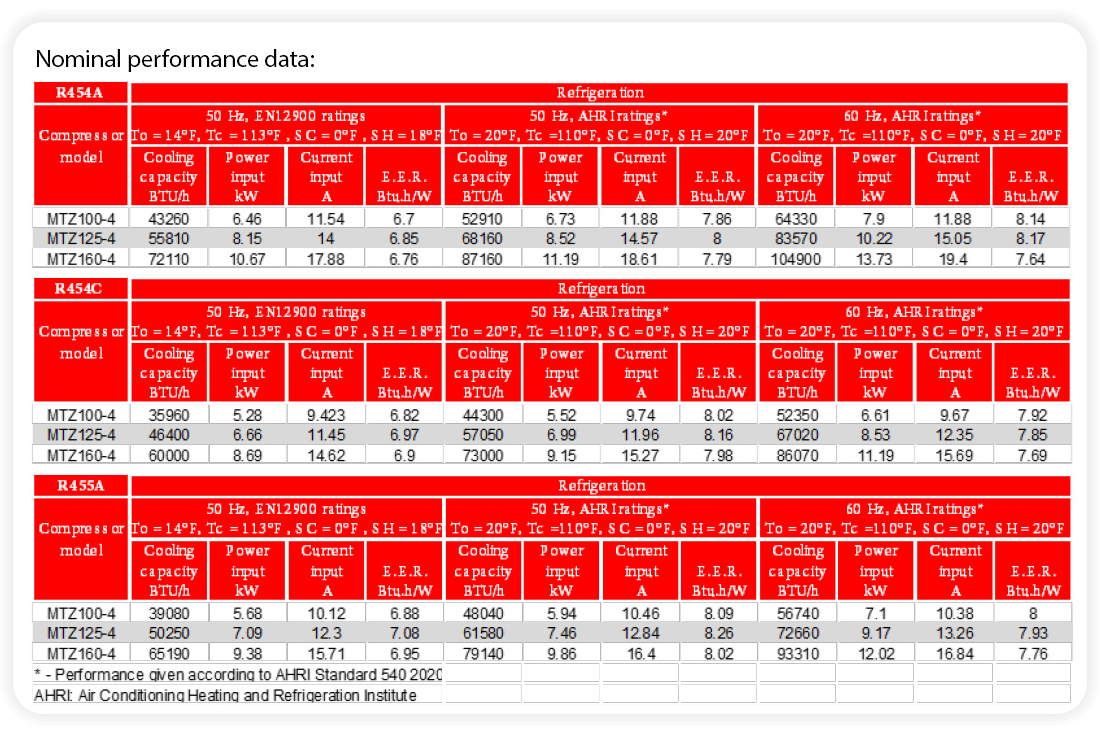

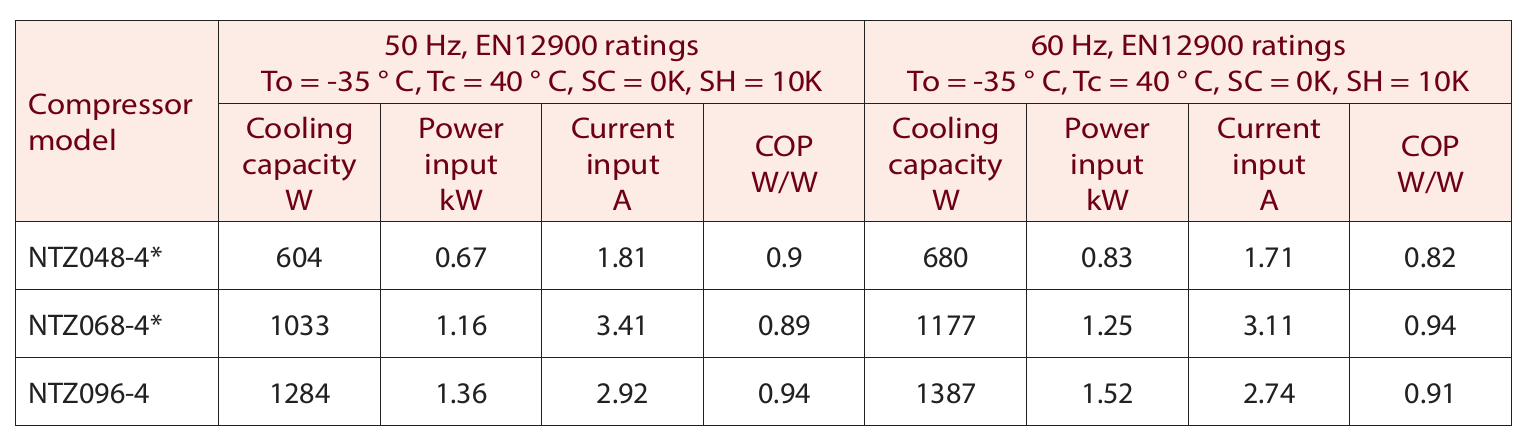

Nominal performance data

R454A/C and R455A are zeotropic refrigerants with a temperature glide of about 6 to 12K and must be charged in the liquid phase. To prevent oil dilution, a crankcase heater is recommended. It protects against refrigerant migration and maintains the oil temperature 8–10K above the saturated LP temperature. Tests should be conducted to ensure an appropriate oil temperature under all conditions. A PTC crankcase heater is recommended for all stand-alone compressors and split systems. Under extreme conditions, a belt-type crankcase heater may be used in addition to the PTC heater.

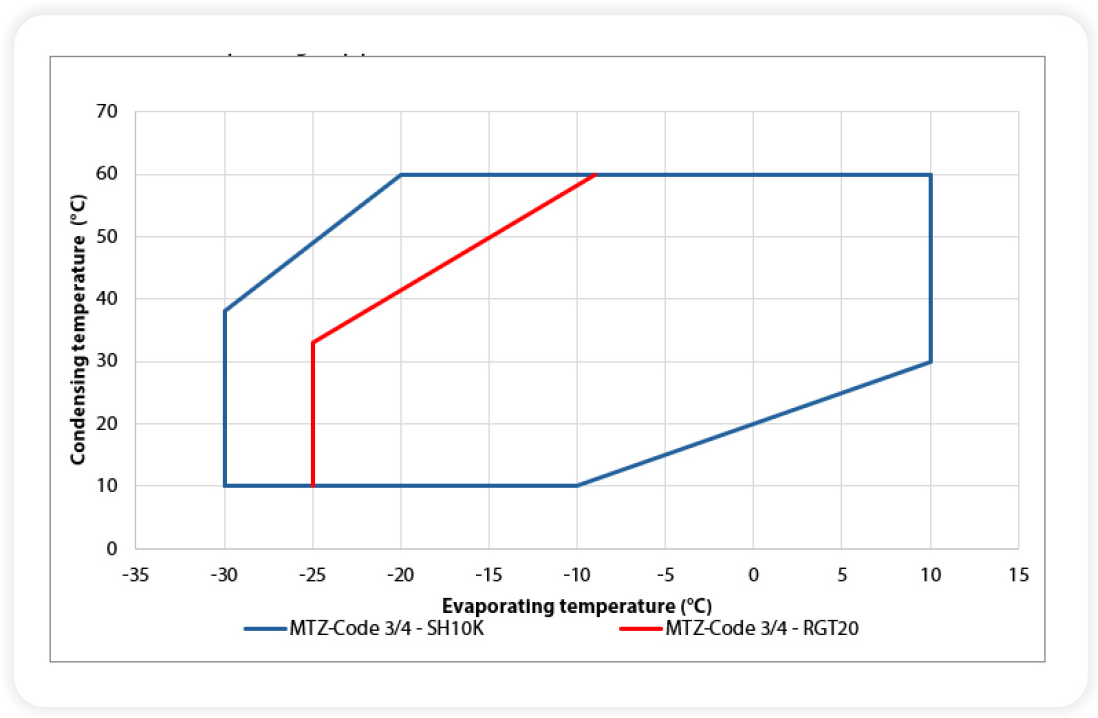

Please follow the operating map presented below

There is no change in the ordering process; compressor codes remain the same. Compressor nameplates will specify Refrigerant Group 1, which includes hazardous fluids such as flammableefrigerants according to PED Classifiction. Compressors will also be marked with a flammable efrigerant logo to ensure clear identifiction and compliance with safety standards.

For more information, please refer to the CoolSelector2 selection program available at www.danfoss.com.

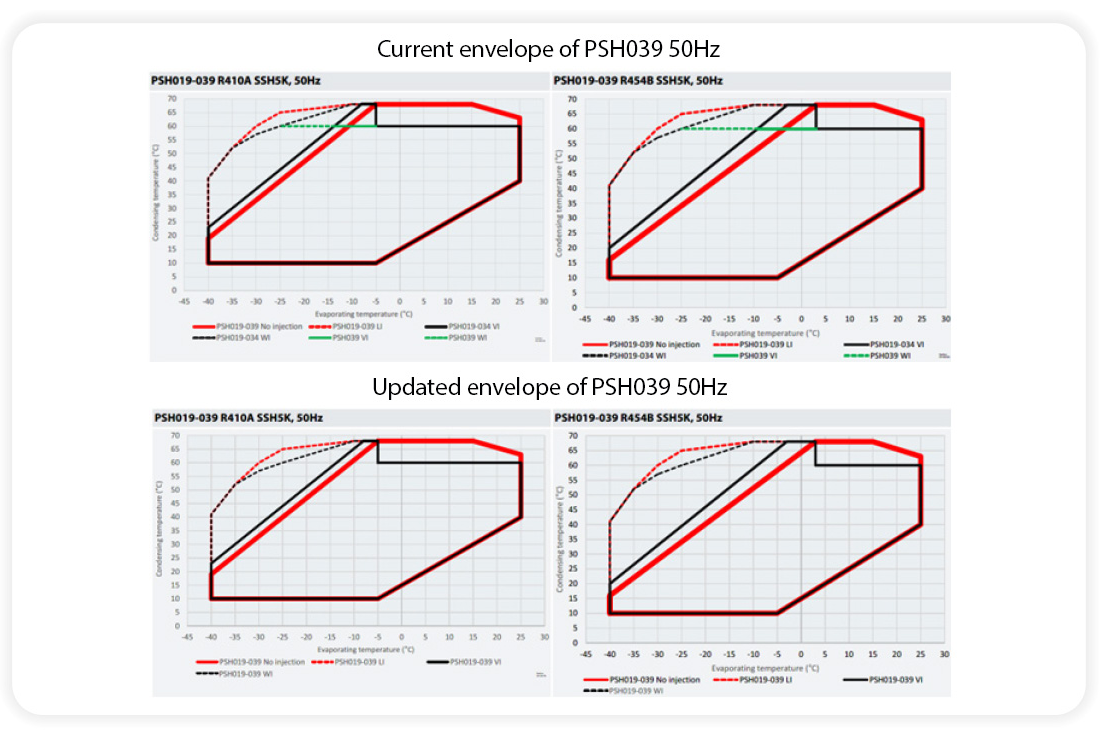

Starting from last October, the 50Hz VI envelope of the PSH039A4ELA/FLA had been released with a maximum condensing temperature of 60 °C, compared to other PSH models at 68 °C . We are pleased to announce that after developing a new overload protector, the envelope can now match the area of other models, efective from August 2025.

Summary of the key points

Envelope extension: The 50Hz VI envelope of PSH039A4ELA/FLA is extended, with no changes to the 60Hz envelope.

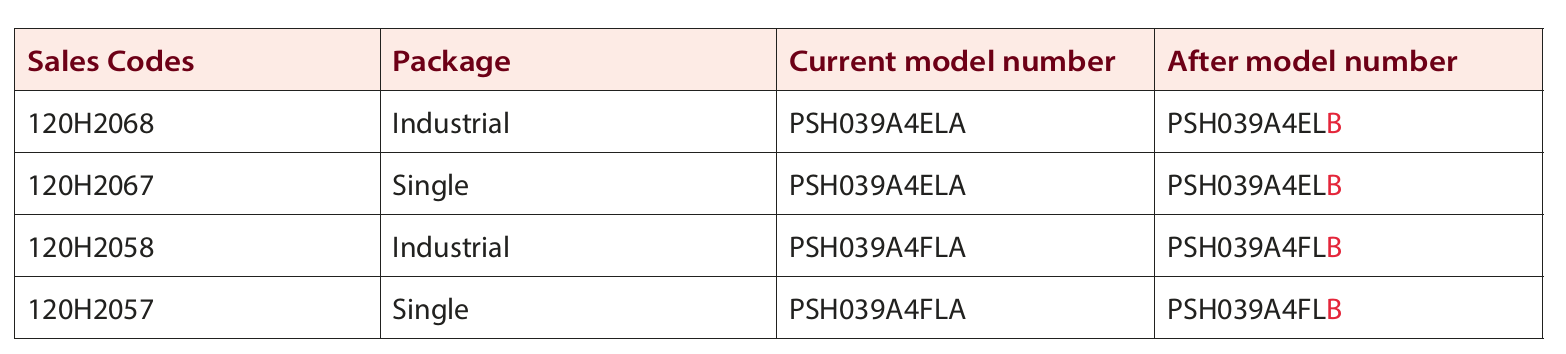

Model naming: To diferentiate old and new models, the index of technical model name will be upgraded, while the sales code remains unchanged.

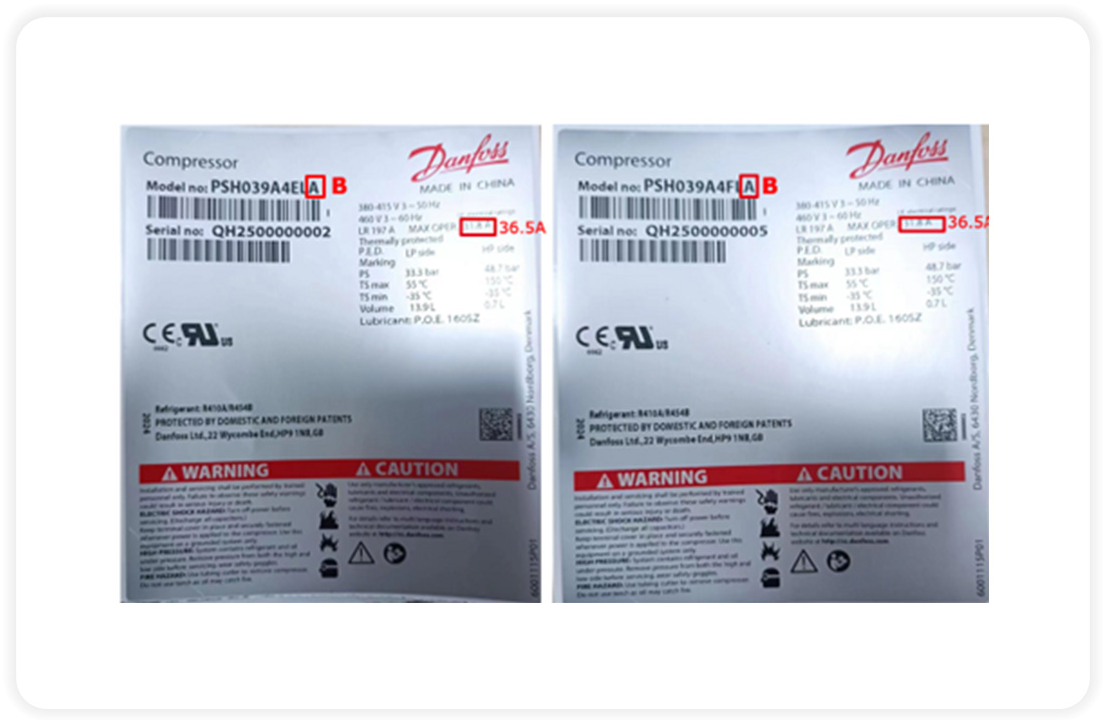

Electrical specifictions:

Updates due to the new protector:

- MOC changes from 31.8A to 36.5A

- RLA changes from 29A to 30.7A

Nameplate Update:

The nameplate will reflet these changes.

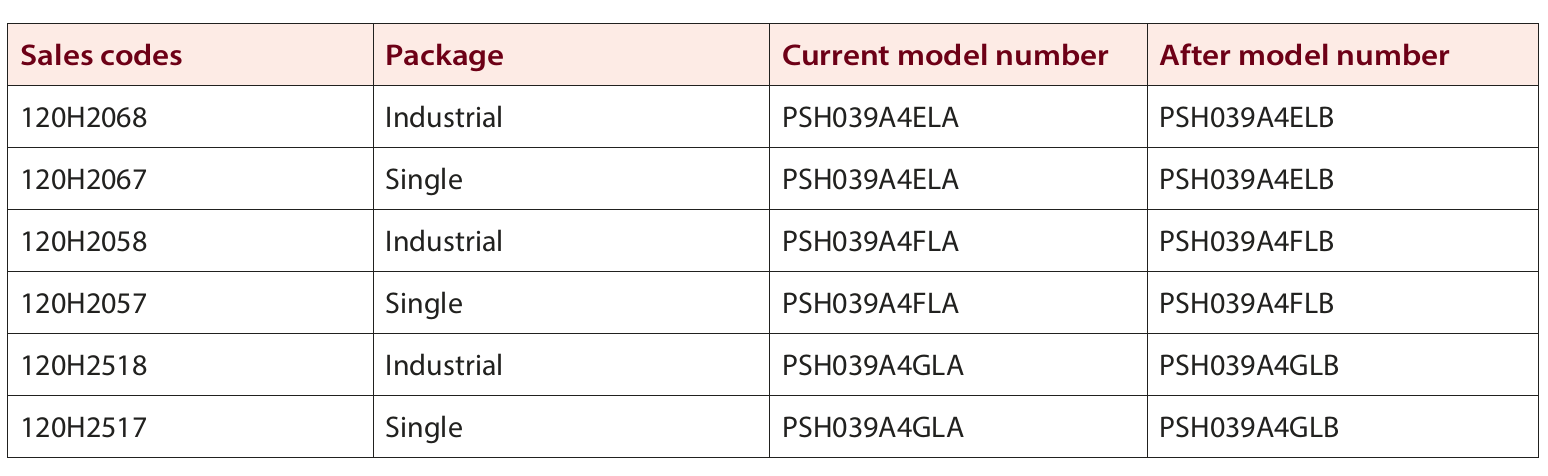

PSH039A4GLA model update:

Shares the same motor and protector update as PSH039A4ELA/FLA, changing model name to PSH039A4GLB and RLA updated to 30.7A. The technical model’s name on nameplate will be updated accordingly. With no impact on the envelope and other parameters.

Afected products

Danfoss encourages the further development and application of low-GWP refrigerants and will enable our customers to achieve these GWP goals while continuing to enhance the energy efficiey of our refrigeration equipment.

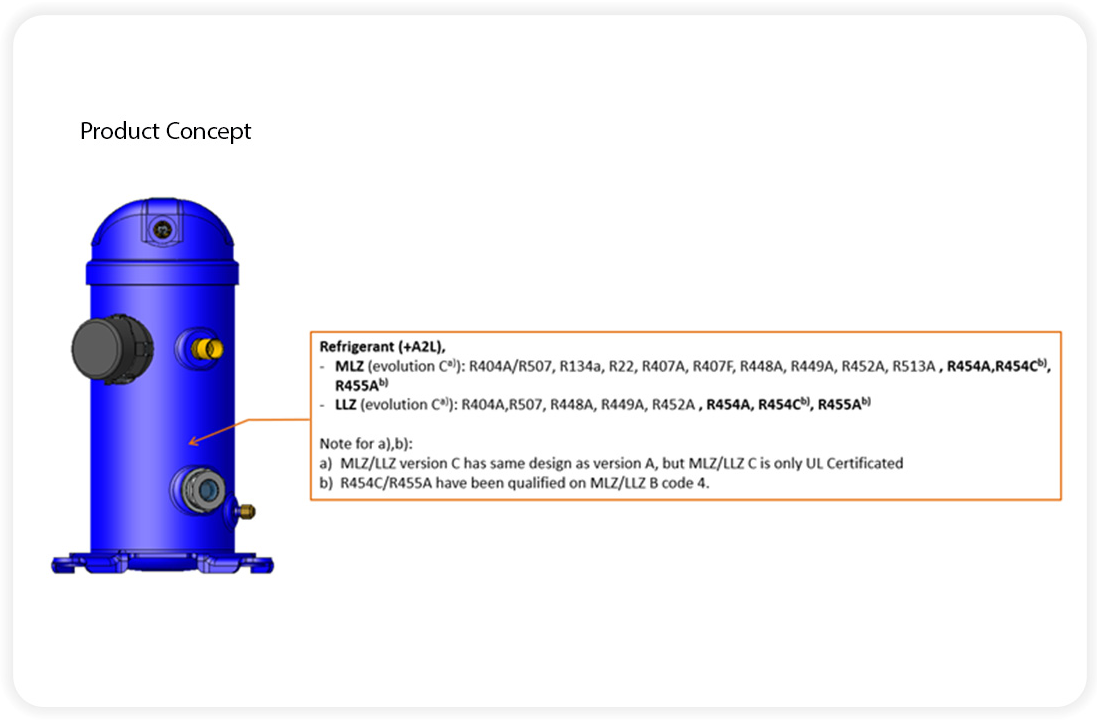

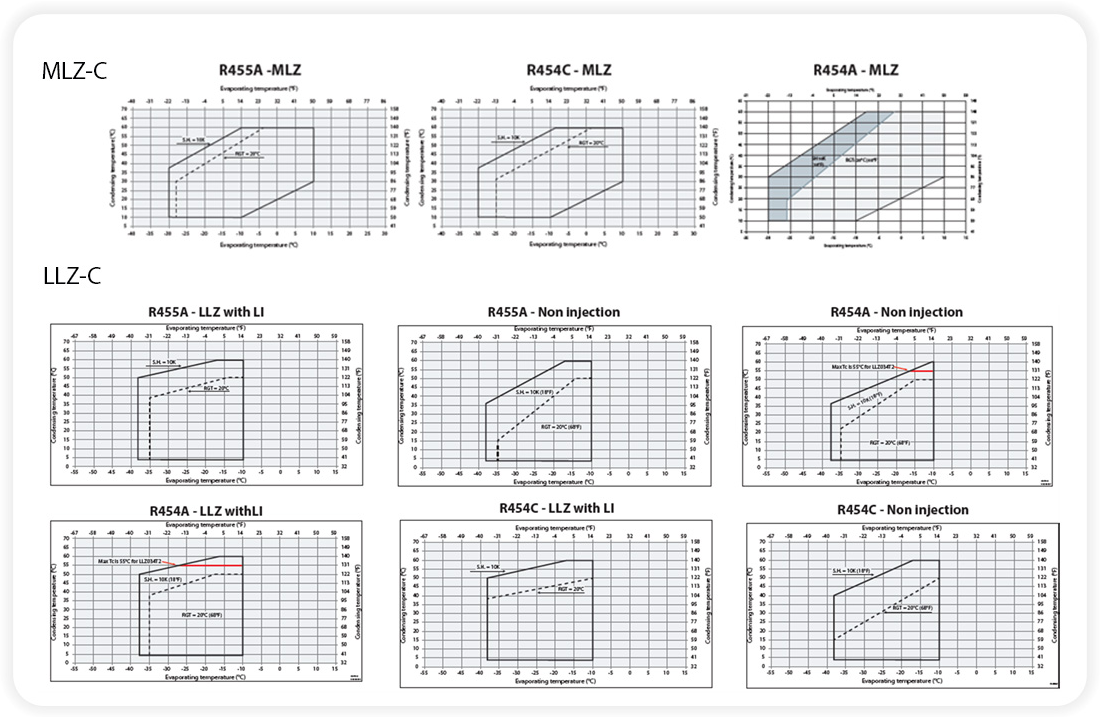

Since 2023, We have released MLZ/LLZ version B models filled with POE oil RL46HB(215Z) approved with new A2L refrigerants R454C and R455C, which is also allowed with A1 low-GWP refrigerants R448A,R449A,R134a, R513 and so on. Now, new models MLZ/LLZ (motor code 1& code 2) version C (UL only) with refrigerant R454A, R455A, R455C have been released in June 2025.

Product Concept

Envelop with A2L refrigerants

Label

For detailed capacities, operation map and so on, please refer to Coolselector2. Polynomial coefficits are also available directly in Coolselector2 or via the intranet portal.

For further information, please refer to the application guideline.

Afected products

Models, refer to the attached table of order information.

MLZ015 -19 -21 -26 -30 -38 code1

MLZ015 -19 -21 -26 -30 -38-45-48-58-66-76,

LLZ013-15-18-24-34 code2

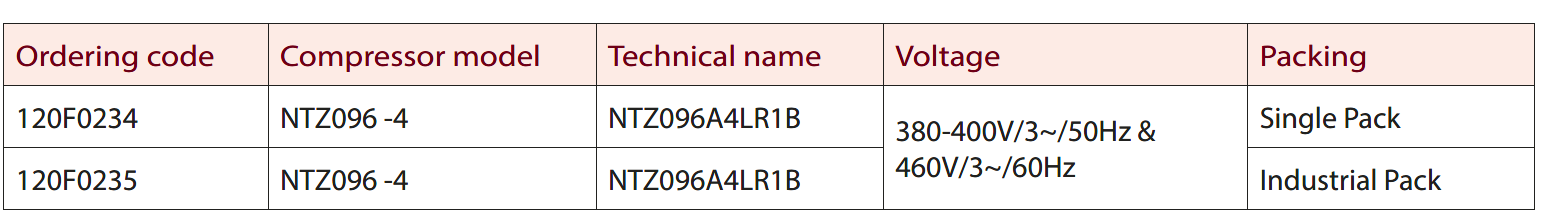

Danfoss is committed to providing innovative and sustainable solutions for the refrigeration industry. We are pleased to share important information regarding the qualifiction of NTZ096-4 compressors with R454C refrigerant. The refrigeration industry has made significat strides in reducing the use of ozone-depleting refrigerants. With the increasing focus on climate change and global warming, the adoption of synthetic refrigerants with low Global Warming Potential (GWP) is becoming more prevalent. Danfoss supports the development and application of these low-GWP refrigerants and is dedicated to enabling our customers to achieve their sustainability goals while enhancing the energy efficiey of their refrigeration equipment.

NTZ096-4 Compressor qualifiction

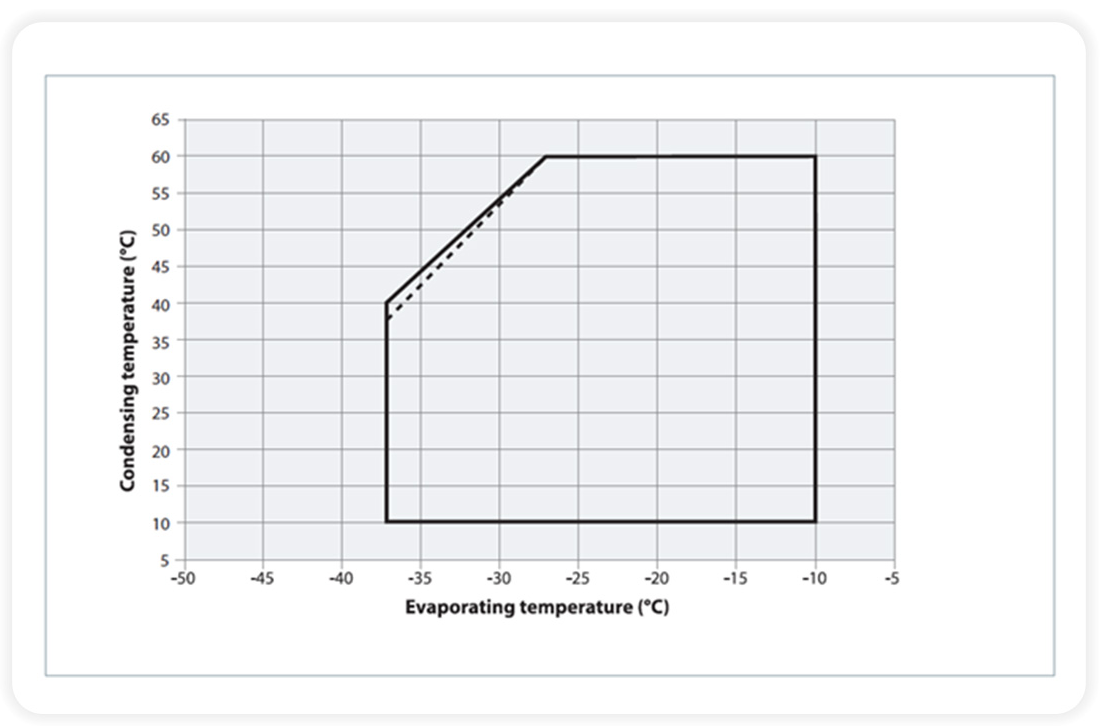

We are pleased to announce that the NTZ096 model, motor code 4 (refer to models listed below), is now approved for use with R454C refrigerant. R454C can be used as a replacement for R404A and R507 in various applications. Please refer to the operating map for specific usage guideline.

Key details

- Refrigerant Compatibility: NTZ096-4 models listed below are qualified or use with R454C refrigerant, classified as efrigerant Group

- Low GWP: R454C has a GWP below 150.

- Flammability: This refrigerant is classified as A2L, indicting low flammabiliy. Please adhere to all relevant European regulations and directives (EN378, EN60335) and EPA rulings in the US regarding the safe use of A2L refrigerants. Outside of Europe and the USA, please refer to local regulations.

The following compressor models are afected

Implementation date

This change is efective from July 2025. All NTZ096-4 compressors, starting with serial number 1009503203, efective July 9th 2025, are qualified with R454Crespecting operating map presented on the next page.

Operating map (R454C with SH=10K):

Note: Compressors (one-cylinder models) have been qualified peviously.

Recommendations for R454C usage:

- R454C is a zeotropic refrigerant with a temperature glide of approximately 8K and must be charged in the liquid phase.

- Even though NTZ compressors are loaded with 175PZ oil, R454C can dilute the oil. To prevent lubrication issues, a crankcase heater must be used. Maintain the oil temperature 8–10K above the saturated LP temperature of the refrigerant. Conduct thorough tests to ensure proper oil temperature under all ambient conditions.

- A PTC crankcase heater is recommended for all stand-alone compressors and split systems due to its self-regulat- ing properties. In extreme low-temperature conditions, a belt-type crank-case heater can be used in addition to the PTC heater, positioned close to the oil sump for efective heat transfer. However, this is not the preferred solution for one- and two-cylinder compressors.

For further details, please refer to the following application guidelines. The CoolSelector2 selection program is available at www.danfoss.com.

Customer impact:

The ordering process remains unchanged; compressor codes will stay the same. Compressor nameplates will indicate Refrigerant Group 1, which includes hazardous fluids like flammableefrigerants according to PED Classifiction. Compressors will also feature a flammable efrigerant logo for clear identifiction and safety compliance.

Looking to further enhance the performance of the ETS 5M portfolio and to extend the use of this product to more applications, Danfoss releases new models of ETS 5M valves and coils. The new design comes with improved robustness, reliability and an extended standard ofering.

The new ETS 5M valves come with either unipolar or bipolar coils, to enable management with EKE 100 superheat controller and valve driver range or third-party controllers.

From July 28th, 2025, Danfoss starts to replace existing ETS 5M models with new valve and coil design. Migration should be completed by 31st December 2026.

Sales codes are available for the new models of the valves and of the coils.

Please work with your local account manager during this transition to ensure you have the new code numbers set up in your system to avoid any problems during the migration.

Description

The new ETS 5M coil features following specifictions:

Valves and coils:

- Broader ambient temperature range (-40 to +80 °C)

- UL 429 certified (vailable in Q4 2025)

Coils:

- Wire gauge AWG#24 compatible with all types of electric connectors/plugs

- Bi-polar coil enables presetting in Danfoss controllers/drivers EKE/EKF

- Reverse sequence wiring to fit with 3d party controller • Simple and more robust “Clip & Turn” fixtion

- Higher IP enclosure (IP67)

- Market standard wiring and colour code, same as ETS 6 and ETS 8M

- More compact and lightweight

- Better lead time and faster reaction on customizations

The valve is adjusted with an additional fixing ing outside of the rotor tube to clip the coil. Inner valve design and performance are unchanged.

Please note that the existing valve/coil are NOT compatible with the new design.

Food Retail

Danfoss announces a new software release of the ADAP-KOOL™ System Manager 800A series. Please note, a new Danux package (4.14.016.194) accompanies this release and it is recommended to be installed prior to loading the AK-SM800A application update. Both packages can be found on ADAP-KOOL support site.

Software package 4.3.1 requires Danux 4.14.016.194.

Software release 4.3.1 security certifiction

As part of our ongoing commitment to product security and regulatory compliance, we are pleased to inform you that AK-SM800A software version 4.3.1 complies with the latest cybersecurity requirements under the Radio Equipment Directive (RED) 2014/53/EU, including the upcoming provisions outlined in Delegated Regulation (EU) 2022/30, efective from August 1, 2025.

These new EU requirements apply to all radio equipment with internet connectivity and/or the ability to process personal data, and include safeguards to:

- Prevent unauthorized access and data breaches

- Protect against misuse of networks and services

To support compliance with these enhanced regulations, our development processes follow cybersecurity-by-design principles and are certified according to IEC 62443-4-1, the internationally recognized standard for secure product development. This certifiction demonstrates our structured approach to managing cybersecurity risks throughout the entire product lifecycle.

Our goal is to ensure that our customers benefit fom solutions that are not only compliant with EU regulations but also aligned with global cybersecurity best practices reinforcing trust and reliability in connected environments.

Important Changes

- One key change is that the Service Tool (ST-500) port is now disabled by default. This helps reduce potential exter nal access risks. If remote access via the Service Tool is needed, the port can be temporarily enabled through the security settings, and we strongly recommend disabling it again after use.

- Additionally, to further strengthen system protection, all new user accounts are now required to follow stronger password rules, including minimum character length and complexity. Existing user accounts are not afected unless they are required to change their password.

These updates are in line with the industry’s best practices and regulatory expectations, and they support our commitment to delivering secure and reliable system solutions for our customers.

Software Release 4.3.1 main highlights

Security:

- Cryptographic validation of AK-SM800A package

- Hardened UPK update against file injetion

- Permanent disabling of SSH connection

- Post-authenticated external control of system web interface configuation settings

- Sanitization of input fields - potect from code injection

- System now requires user to change password immediately after first loin

- Update (block) access to serial console for the root user

- Prevent user corruption of webserver-configuation

- Update nginx and mail to support TLS version 1.2

- Block sweet32 cipher suite (Nginx)

- Add user message under all HTTP/S configuation areas

- New user accounts require strong passwords

New features:

- Add new A2L Refrigerants for 800A Rack Control

- Add 90-day password/account expiry

- MCX Lighting control - Customer request import Analog Input

Bug fixes:

- Resetting Issue found when a 800A converted database from 800 that had Alarm Logger

- Session manager does not allow to create a new password when the old expires

- NTP timing issue

Software Installation

Perform a unit backup and check for any open alarms before proceeding with update. R4.3.1 requires Danux 4.14.016.194 to be installed firs, followed by the 4.3.1 fimware package. After installation of Danux and 4.3.1 packages be sure to perform a ‘soft reset’ via the ‘Config -> omm screen’ and use the ‘Press to reset’ this unit button.

Step1 (install Danux 4.14.016.194.lpk)

- Using StoreView Browser 5 / StoreView Web select OS update and proceed with Danux upgrade

- Important notes: This file sie package is large and depending on your network speed may take 10+ minutes to complete. Do not interrupt power during the OS update. For systems utilizing DHCP it is advised that this update is per- formed locally, as IP address change is possible after re-booting.

Step 2 (update System Manager fimware (package 4.3.1 spk))

- Using StoreView Browser 5 / StoreView Web or local USB Flash drive, select OS update and proceed software upgrade. Do not interrupt power during the software update.

Step 3 (perform soft reset to fully apply packages)

- After installation of Danux and 4.3.1 packages be sure to perform a ‘soft reset’ via the ‘Config -> omm screen’ and use the ‘press to reset this unit’ button.

Step 4 (review)

- After installation is complete, review for correct system operation.

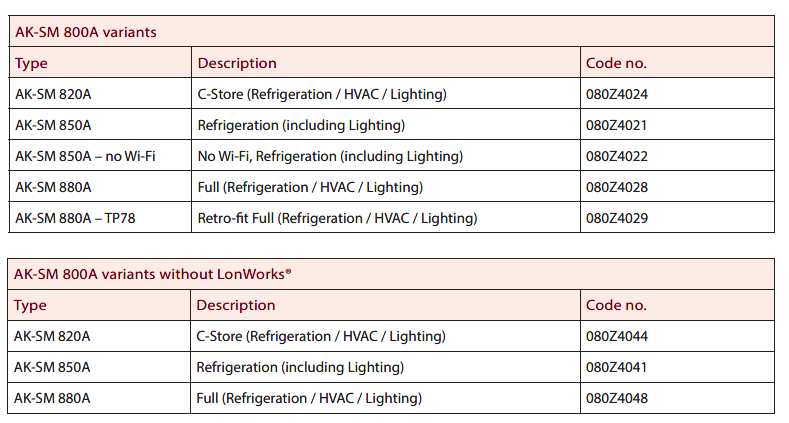

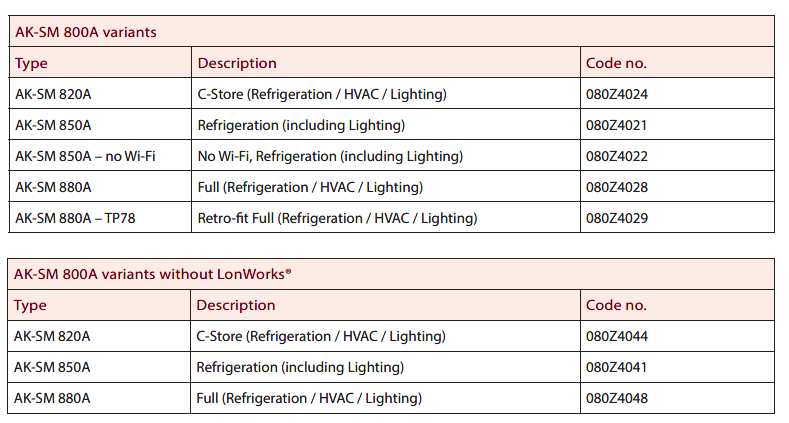

Approved products

The table below shows approved AK-SM 800A portfolio versions suitable for software 4.3.1

Timing and stock

Package 4.3.1 is released for general update and is available via ADAP-KOOL® support site. Stock units will not be recalled or updated.

Security

To help keep your Danfoss products secure and protected, we emphasize implementing cyber security at best practices to maximize your protection against malicious attacks.

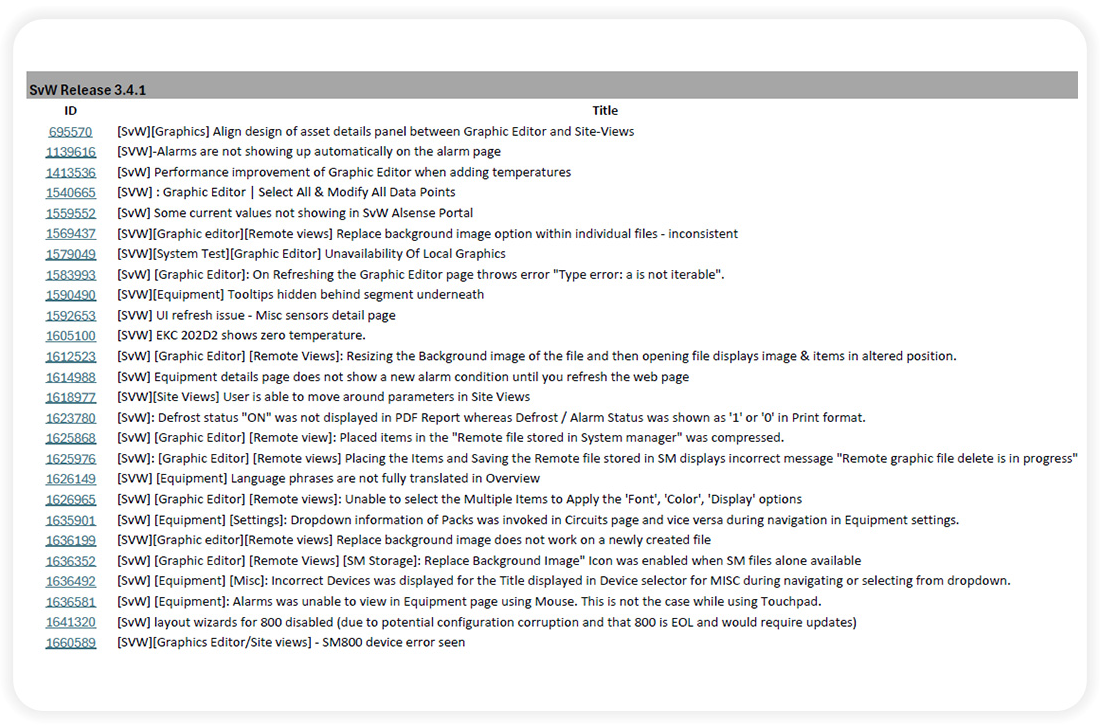

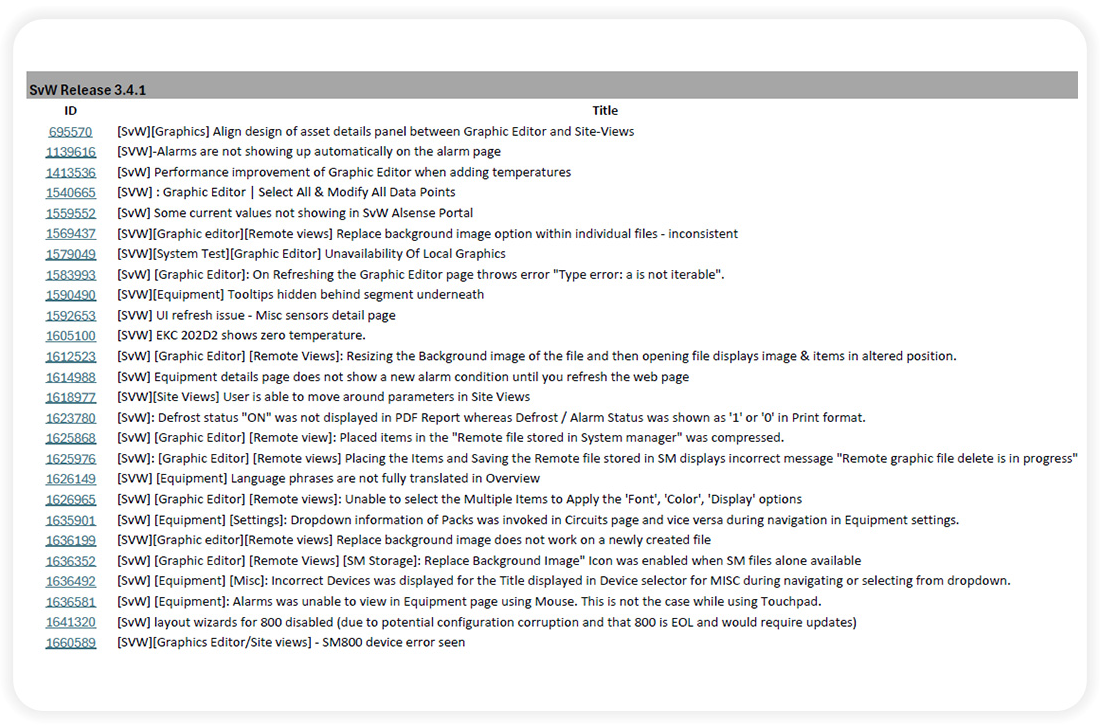

Danfoss is pleased to announce that a new version of Storeview Web (SvW) is available, version 3.4.1. The main highlights of this release include improvements for usability, configuation and interface and various bug fies.

Timing and availability

Storeview Web (3.4.1) is released from Danfoss in June 2025 but may take up to 24 hours to take efect depending on browser versions. Storeview Web (3.4.1) is available via browser (svw.danfoss.com) and via desktop app, available from same location. Please note that Storeview Web requires connectivity to your System Manager. Special Notes

Support for the End Of Life (EoL) AK-SM800 Configuation wizards in SvW has been blocked due to unpredictable results. Addressing this issue would require modifiction to the AK-SM800, which is no longer available for service.

Afected products

StoreView Web supports: AK-SM 800 series (Recommended VG08.095 and above) AK-SM 800A series (Recommended R3.0.12 spk and above)

More information and news about the current and future updates can be found on Danfoss.com.

Storeview Web 3.4.1- Change Log

Industrial Refrigeration

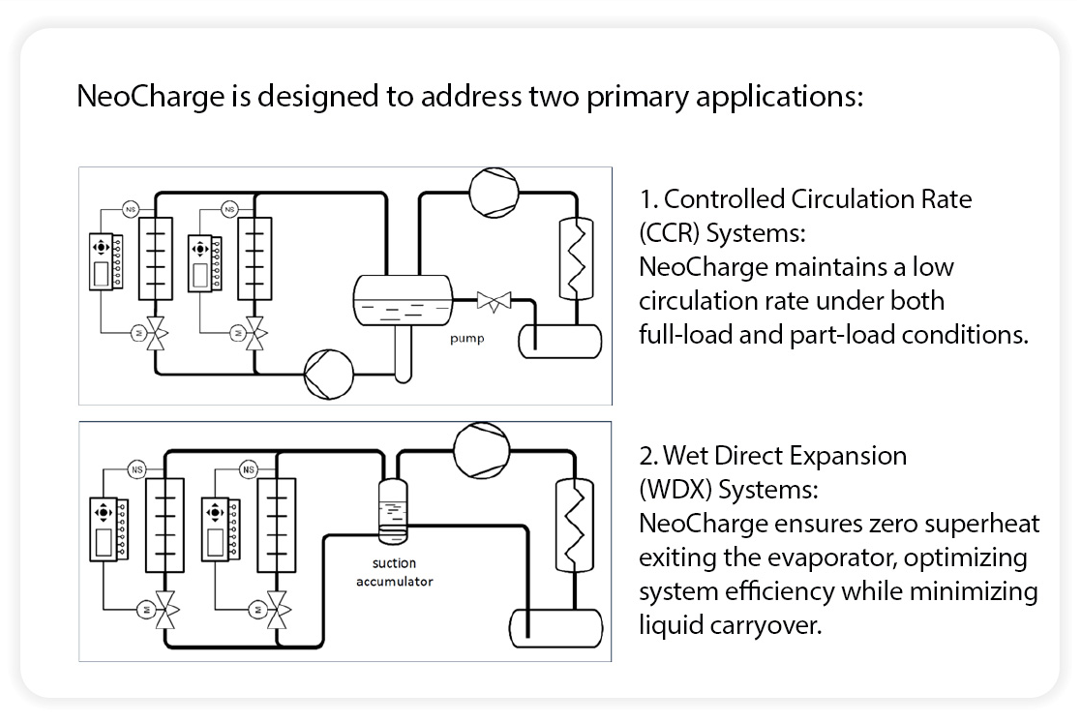

We are pleased to announce the release of the groundbreaking Danfoss NeoCharge Solution designed for and tailored to the needs of industrial refrigeration. NeoCharge is a simple, unique technology that reduces the system charge by controlling the refrigerant injection into the evaporator keeping high performance.

How NeoCharge™ creates value

Increase safety

- Significantly reduces ammonia charge, meeting regulatory standards

- Provide the required cooling to all assets

- Ensures safe operation with built-in features that minimize downtime

Optimize Performance

- Use the charge in the most efective way

- Compatible with all ammonia refrigeration systems, facilitating easy retrofittin

- Ofers a “plug n’ play” installation process, ideal flow new build and existing systems

Maximize efficiey

- Reduce energy costs by up to 20%

- Eliminates superheat in Direct Expansion (DX) systems

- Increase capacity by up to 40% using the same refrigerant charge

- Reduce new system footprint

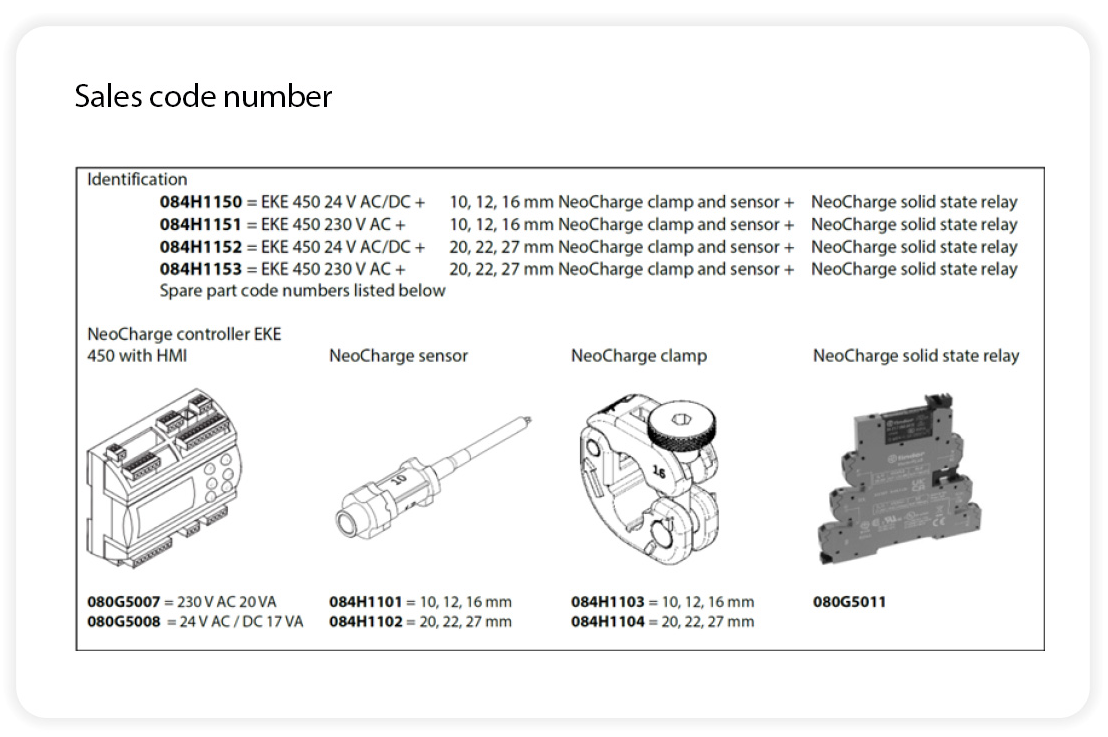

The NeoCharge Solution is a package that includes

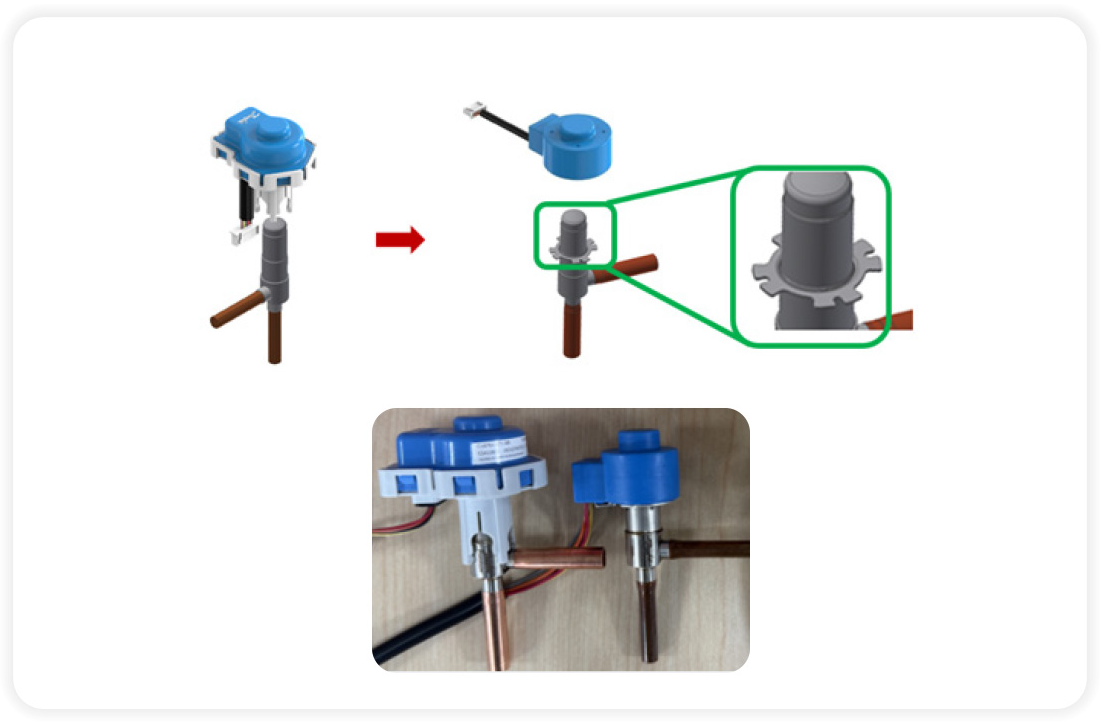

- NeoCharge Sensor: Indicates the amount of liquid at the evaporator outlet

- NeoCharge Sensor-Clamp: Used for attaching the sensor to the evaporator tube

- EKE 450 Controllers: Controls the valve based on the sensor signal

- Solid-state relay: for NeoCharge sensor external power supply.

For more information, please visit our Danfoss Store or contact your local sales representative.

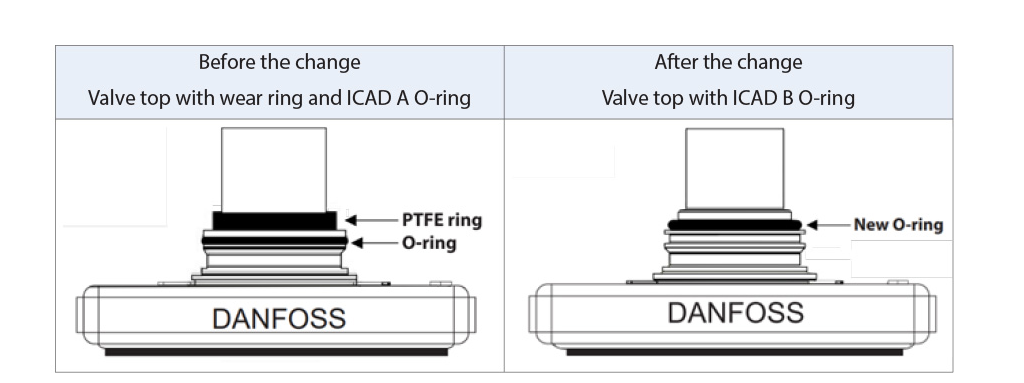

Due to introduction of new ICAD B actuator and phase-out of ICAD A version, it was decided to implement new O-ring for ICAD B version in all ICM, ICMTS valves, CVE pilot valves and ICM modules in ICF valve stations.

New ICAD B O-ring is fited in new location, in a place where ICAD A wear ring was seated before. New ICAD B O-ring has diferent size and diameter and cannot be used for ICAD A actuator.

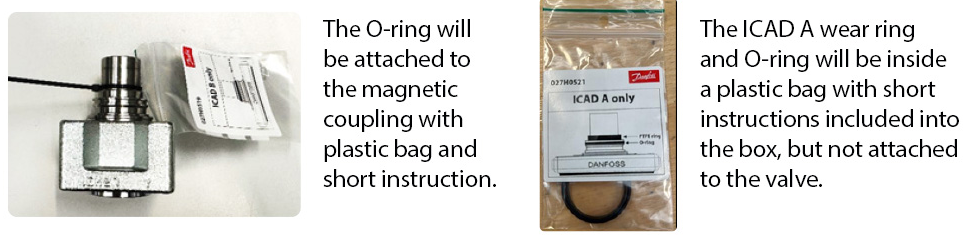

Fully assembled valves will be delivered only with new ICAD B O-ring. The O-ring will be attached to the magnetic coupling with plastic bag and short instructions (please see the photo below). This is done due to risk of the O-ring falling off y transportation.

If the valve needs to be coupled with ICAD A, the wear ring and ICAD A O-ring must be ordered separately:

- Spare part 027H0356 for ICM 20-32

- Spare part 027H0357 for ICM 40-150, ICMTS and CVE

Top modules for ICM 20-65 and ICMTS modules, which are often used as spare parts, will be delivered both with ICAD B O-ring and ICAD A wear ring and O-ring.

- The ICAD B O-ring will be attached to the magnetic coupling with plastic bag and short instructions.

- The ICAD A wear ring and O-ring will be inside a plastic bag with short instructions in- cluded into the box, but not attached to the valve (see photo on the left)

Implemented for the production in Poland from beginning of June, production in China and Mexico will implement the change by end of June 2025. First delivery of changed products depends also on parts being in transit and stored in stocks.

For more information, please visit our Danfoss Store or contact your local sales representative.

Software updates

Danfoss announces a new software release of the ADAP-KOOL™ System Manager 800A series. Please note, a new Danux package (4.14.016.194) accompanies this release and it is recommended to be installed prior to loading the AK-SM800A application update. Both packages can be found on ADAP-KOOL support site.

Software package 4.3.1 requires Danux 4.14.016.194.

Software release 4.3.1 security certifiction

As part of our ongoing commitment to product security and regulatory compliance, we are pleased to inform you that AK-SM800A software version 4.3.1 complies with the latest cybersecurity requirements under the Radio Equipment Directive (RED) 2014/53/EU, including the upcoming provisions outlined in Delegated Regulation (EU) 2022/30, efective from August 1, 2025.

These new EU requirements apply to all radio equipment with internet connectivity and/or the ability to process personal data, and include safeguards to:

- Prevent unauthorized access and data breaches

- Protect against misuse of networks and services

To support compliance with these enhanced regulations, our development processes follow cybersecurity-by-design principles and are certified according to IEC 62443-4-1, the internationally recognized standard for secure product development. This certifiction demonstrates our structured approach to managing cybersecurity risks throughout the entire product lifecycle.

Our goal is to ensure that our customers benefit fom solutions that are not only compliant with EU regulations but also aligned with global cybersecurity best practices reinforcing trust and reliability in connected environments.

Important Changes

- One key change is that the Service Tool (ST-500) port is now disabled by default. This helps reduce potential exter nal access risks. If remote access via the Service Tool is needed, the port can be temporarily enabled through the security settings, and we strongly recommend disabling it again after use.

- Additionally, to further strengthen system protection, all new user accounts are now required to follow stronger password rules, including minimum character length and complexity. Existing user accounts are not afected unless they are required to change their password.

These updates are in line with the industry’s best practices and regulatory expectations, and they support our commitment to delivering secure and reliable system solutions for our customers.

Software Release 4.3.1 main highlights

Security:

- Cryptographic validation of AK-SM800A package

- Hardened UPK update against file injetion

- Permanent disabling of SSH connection

- Post-authenticated external control of system web interface configuation settings

- Sanitization of input fields - potect from code injection

- System now requires user to change password immediately after first loin

- Update (block) access to serial console for the root user

- Prevent user corruption of webserver-configuation

- Update nginx and mail to support TLS version 1.2

- Block sweet32 cipher suite (Nginx)

- Add user message under all HTTP/S configuation areas

- New user accounts require strong passwords

New features:

- Add new A2L Refrigerants for 800A Rack Control

- Add 90-day password/account expiry

- MCX Lighting control - Customer request import Analog Input

Bug fixes:

- Resetting Issue found when a 800A converted database from 800 that had Alarm Logger

- Session manager does not allow to create a new password when the old expires

- NTP timing issue

Software Installation

Perform a unit backup and check for any open alarms before proceeding with update. R4.3.1 requires Danux 4.14.016.194 to be installed firs, followed by the 4.3.1 fimware package. After installation of Danux and 4.3.1 packages be sure to perform a ‘soft reset’ via the ‘Config -> omm screen’ and use the ‘Press to reset’ this unit button.

Step1 (install Danux 4.14.016.194.lpk)

- Using StoreView Browser 5 / StoreView Web select OS update and proceed with Danux upgrade

- Important notes: This file sie package is large and depending on your network speed may take 10+ minutes to complete. Do not interrupt power during the OS update. For systems utilizing DHCP it is advised that this update is per- formed locally, as IP address change is possible after re-booting.

Step 2 (update System Manager fimware (package 4.3.1 spk))

- Using StoreView Browser 5 / StoreView Web or local USB Flash drive, select OS update and proceed software upgrade. Do not interrupt power during the software update.

Step 3 (perform soft reset to fully apply packages)

- After installation of Danux and 4.3.1 packages be sure to perform a ‘soft reset’ via the ‘Config -> omm screen’ and use the ‘press to reset this unit’ button.

Step 4 (review)

- After installation is complete, review for correct system operation.

Approved products

The table below shows approved AK-SM 800A portfolio versions suitable for software 4.3.1

Timing and stock

Package 4.3.1 is released for general update and is available via ADAP-KOOL® support site. Stock units will not be recalled or updated.

Security

To help keep your Danfoss products secure and protected, we emphasize implementing cyber security at best practices to maximize your protection against malicious attacks.

Danfoss is pleased to announce that a new version of Storeview Web (SvW) is available, version 3.4.1. The main highlights of this release include improvements for usability, configuation and interface and various bug fies.

Timing and availability

Storeview Web (3.4.1) is released from Danfoss in June 2025 but may take up to 24 hours to take efect depending on browser versions. Storeview Web (3.4.1) is available via browser (svw.danfoss.com) and via desktop app, available from same location. Please note that Storeview Web requires connectivity to your System Manager. Special Notes

Support for the End Of Life (EoL) AK-SM800 Configuation wizards in SvW has been blocked due to unpredictable results. Addressing this issue would require modifiction to the AK-SM800, which is no longer available for service.

Afected products

StoreView Web supports: AK-SM 800 series (Recommended VG08.095 and above) AK-SM 800A series (Recommended R3.0.12 spk and above)

More information and news about the current and future updates can be found on Danfoss.com.

Storeview Web 3.4.1- Change Log

Technical literature new and updated

- Data sheet - Pressure transmitter CANopen, DST P10B

- Data sheet - Solenoid coil type BB, BE, BF, BG, and BN

- Data sheet - Electric regulating valves Type CCMT 3L, 5L, 8L and 10L

- Data sheet - Electric expansion valve Type ETS 5M

- Application guide - Danfoss scroll for refrigeration LLZ Evolution C (with POE oil) Low temperature

- Application guide - Danfoss Scroll for Refrigeration MLZ Evolution C (with POE Oil)

- Application guide - Scroll compressors PSG605 to PSG800

- Fact sheet - Optyma™ iCO2 Frequently Asked Questions

- COM Compressor Oil Management brochure

- Data sheet - Strainer, type SFIA

- Data sheet - Hand operated regulating valve, type SREG-SA and SREG-SB 15-40

- User Guide | Intelligent Purging System (IPS 8) Ammonia, UL approved

- Application guide - Industrial Refrigeration systems in Potentially Explosive Atmospheres (Hazards area) ATEX 94/9/EC Directive [Atmosphères EXplosives]

- Application guide - Gas detection in refrigeration systems

All information, including but not limited to information regarding product selection, application or use, product design, weight, dimensions, capacity, or any other technical data of products in product manuals, catalog descriptions, advertisements, etc., whether provided in writing, verbally, electronically, online, or via download, is to be considered purely informative and is binding only if and to the extent explicitly referenced in a quotation or order confi- mation. Danfoss assumes no responsibility for possible errors in catalogs, brochures, videos, and other printed materials. Danfoss reserves the right to make changes to its products without prior notice. This also applies to products already ordered but not delivered, provided such adjustments are possible with-out substantially changing the form, suitability, or function of the product. All trademarks contained in this publication are owned by Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.