SOUTH AFRICA: BMG Electronics used Danfoss drives to support DryTech International in its development of a unique wet screw feeder for use in a platinum operation comprising mine, processing plant, and smelter. This solution improves reliability with elegant synchronization free of servo motion control, reduces costs, and eases maintenance time too.

Learn how BMG Electronics used Danfoss drives to help DryTech International to develop a uniquely efficient wet screw feeder.

Challenge: Unusual material requires unique solution

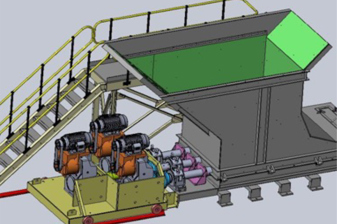

DryTech International developed the wet screw feeder for this plant to deal with unusual characteristics of the material being processed from platinum group metals (PGMs), chrome and base metals. The material is extremely sticky, with a consistency like clay, and needed to be transferred smoothly into a dryer. In addition, this material is received not only from mines within the immediate area in Limpopo province, but also from mines in the Mpumalanga province of South Africa, more than 300 km away. During transit, some composites dry out, while others remain wet.

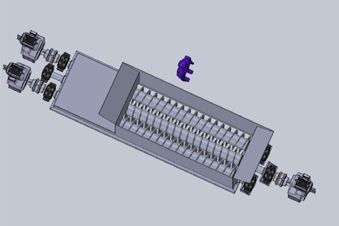

From a mechanical design perspective, the gears required for the feeder would be large-scale, posing some practical challenges when it came to physically fitting into the unit synchronization without the screws clashing. Larger gears would also substantially increase the costs of the wet screw feeders. Ease of maintenance was a further requirement by the plant. The throughput needed from the first wet screw feeder was between 30 and 40 tonnes per hour, with 15 tonnes per hour required for the second feeder.

Solution: Synchronized screw shafts

|

|

|

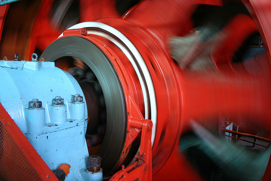

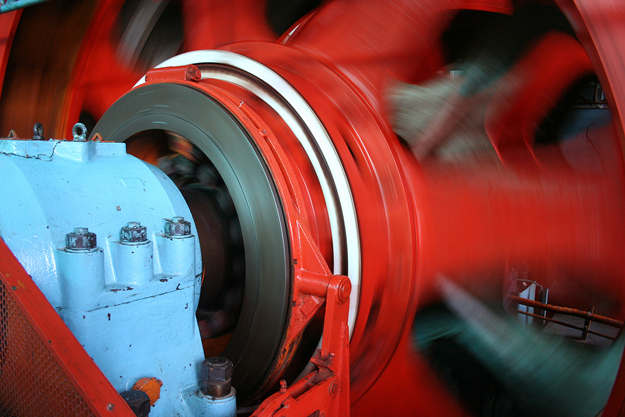

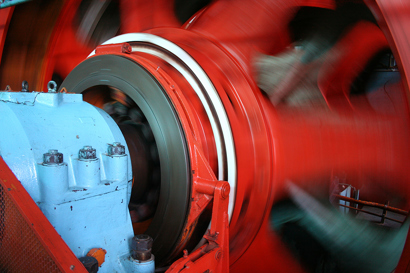

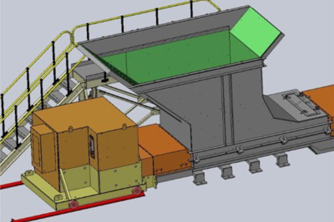

| 3D wet feeder model without guards | 3D wet feeder model with guards | DryTech wet screw feeder setup using FC 302 drives |

DryTech built a trial machine to test the application, and the trial showed that a three-screw shaft was the most effective solution. Although during the trial, the three screw shafts were mechanically linked to one other, the client favoured a solution with independent shafts, electronically synchronized using VLT® AutomationDrive FC 302 units controlling a 22 kW motor/gearbox on each shaft. This was a critical requirement, as all three independent shafts need to rotate in a coordinated manner to help prevent mechanical damage. For example, should one of the motors, gearboxes or shafts become overloaded and slow the motor down, it must be detected by an out-of-synchronization function and all screw shafts stopped. Once the problem is cleared and the application brought back manually, then the application automatically reverts back into the correct synchronized position at start-up, instead of having to return the shaft to a home position manually.

"The Danfoss VLT® AutomationDrive FC 302 offering provided the ideal solution for this client, due to its innovative alternative to the traditional servo control approach for positioning and synchronization operations. The drives are adaptable to the applications through simple parameterization.” explains Stephen Brown, Mining Business Development Manager for Danfoss Turkey, Middle East & Africa

During normal operation, the load on each drive is relatively light – at less than 50 percent motor full load torque (FLT) - but because of the sticky consistency of the material, there are times when higher loads occur. This has proven to be especially true during start conditions or low-feed rate conditions. The 22 kW drives with 22 kW motors are well suited to cope with these conditions, by constantly matching the power to the load. The motors are mounted above the gearbox driving each screw shaft, driving the gearbox via a belt drive.

“We needed the flexibility to be able to adjust the belt pulley ratio during commissioning in order to set the maximum speed, and therefore throughput rate, of the feeder. This also prevents mechanical damage at the belt, which will fail first.”

- Riaan Van Niekerk, DryTech spokesperson

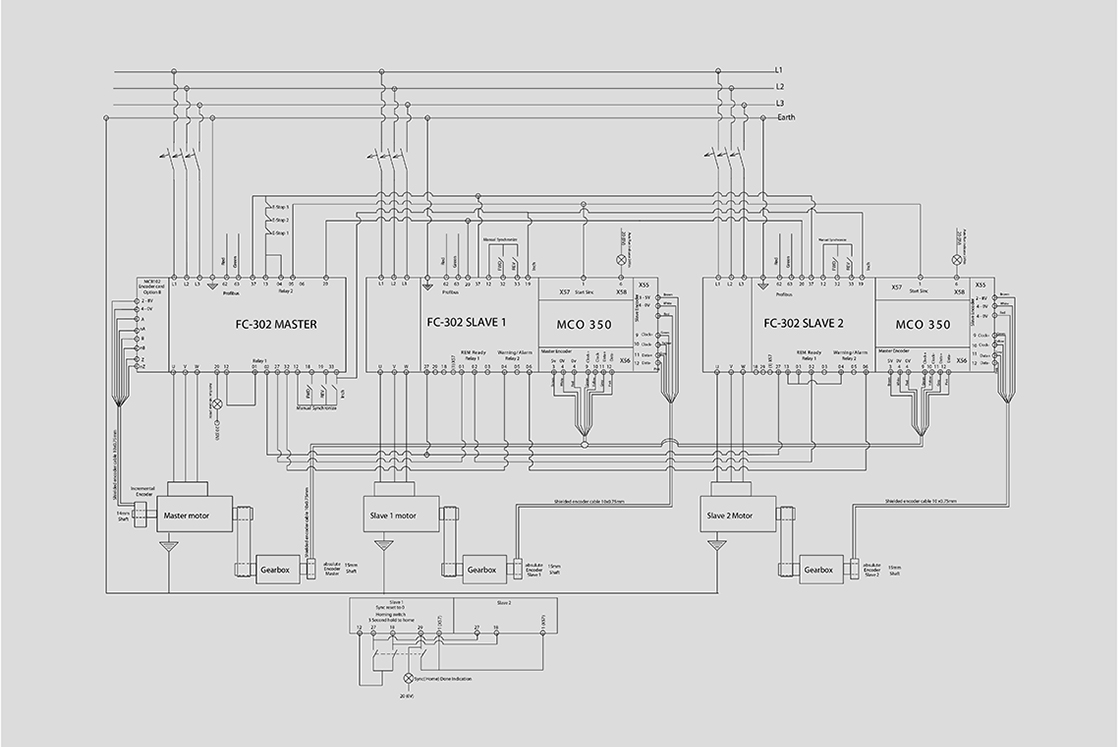

Tighter speed and operation control

The final application set up by Juan Lerm, Field Service Technician at BMG Electronics, comprises three screws connected to the 22 kW motors and reducing gearboxes. The master motor (center motor) is controlled by a VLT® AutomationDrive FC 302 with PROFIBUS® and encoder options.The PROFIBUS® master is the plant control system controlling the operation and speed of this motor according to process requirements. The master motor is fitted with an encoder to increase its dynamic torque response, and the shaft of this motor has a reference encoder to measure the actual screw shaft rotational speed.

The higher the pulses per revolution (PPR), the better the syncing, as the increments are closer to each other, thus increasing the resolution of the feedback.

“In this application we used 8192 PPR multiturn absolute encoders,” explains Mick Baugh, Electronics Manager, Electromechanical Division, BMG. "When the wet feeder needs to run, it gives a ‘start’ command to the master variable speed drive (VSD) via PROFIBUS®. The master VSD then gives the start signals to the follower VSDs.”

The two follower screws are connected to VLT® AutomationDrive FC 302 with a VLT® Synchronizing Controller MCO 350 option also with PROFIBUS® for monitoring purposes. The master encoder is connected to both the MCOs as a master reference, which means that the MCO 350 cards monitor the speed of the master shaft. The follower encoder is fitted on the screw shaft of the follower screws, and these encoders are connected to each respective MCO as a feedback signal.

“The way this works is that the follower effectively mirrors the master encoder: if the master screw shaft runs at a certain speed, the follower MCO card monitors that speed and matches it so that the follower shaft is running in sync with the master reference,” states Baugh.

“If the application stops in an alarm state, all the motors will coast to a stop, and the follower shafts will be out of sync. When a start command is given, the master VSD has a five second delay, so that the screws will ramp up, and the application goes back into sync by itself. The master will then ramp up to the speed reference as per the PROFIBUS® signal.”

If maintenance has been done on the application, the screws will be out of sync. A manual sync was programmed so that the VSDs will go into a second setup, and now each screw can be jogged in forward and reverse to put all the screws back into a sync position. Once the screws are correctly aligned, the technician simply pushes the sync button to give the drive a new zero position. When the application starts up again it will run in sync.

“The fact that the Danfoss VLT® Synchronizing Controller MCO 350 option did not require the writing of a special APOS program was also a significant deciding factor,” Baugh adds.

|

|

|

| Discover the ways in which intelligent drives add value to your operations: VLT® AutomationDrive FC 302 |

Learn more about increasing productivity with Danfoss synchronization, positioning, and cam control | Discover more drive solutions for significant CAPEX and OPEX savings in mining and mineral processing |

| Visit the FC 302 webpage | Read the Motion Control brochure | Read the Mining brochure |

Related applications

-

if (isSmallPicture) {

Drives for conveyors in mining

Drives for conveyors in miningFlexibility to control the speed of long conveyors can help optimize the complete system, reduce bottlenecks and extend motor lifetime.

-

if (isSmallPicture) {

Drives for cranes in mining and mineral processing

Drives for cranes in mining and mineral processingTo optimize crane and hoist performance, Danfoss offers flexible control strategies combined with energy efficiency, operating within stringent safety requirements.

-

if (isSmallPicture) {

Drives for mine ventilation fans

Drives for mine ventilation fansEnsure reliable and economical fan operation both at the surface and underground, with easy integration into Ventilation on Demand (VoD) systems.

-

if (isSmallPicture) {

Drives for pumps in mining

Drives for pumps in miningPumps perform a myriad of tasks throughout mining operations. By investing in performance optimization with Danfoss drives, you can achieve more efficient pumping, better equipment protection and lower operating costs in a lot of different areas.

Related case stories

-

if (isSmallPicture) {

Site assessment secures maximum uptime for K+S

Site assessment secures maximum uptime for K+SGERMANY: Thanks to DrivePro® Life Cycle Services, a K+S potash mine got more uptime and a quick retrofit resulting in a better bottom line.

-

if (isSmallPicture) {

Addressing Dewatering Challenges at an Arizona Mine: VLT® AQUA Drive

Addressing Dewatering Challenges at an Arizona Mine: VLT® AQUA DriveWater presents a significant risk to mining operations, potentially causing equipment damage and environmental contamination. A robust pumping system is required to control the flow of water and remove it from the work site. A large copper mine in Arizona had reached a critical stage where they needed to replace their 250-horsepower (HP) dewatering pump and increase pumping capacity.

-

if (isSmallPicture) {

Maximum power for excavating uphill tunnels

Maximum power for excavating uphill tunnelsFRANCE: Powerful VACON® NXP drives power the Tunnel Boring Machine (TBM) used in construction of a new hydroelectric power plant in the Alpe d’Huez region. The Italian contractor Cogeis operates this TBM to dig a tunnel with a 22% gradient. It’s part of an innovative project which will deliver 100% renewable energy to the grid.

-

if (isSmallPicture) {

VACON® 1000 MV drives power deep pumping at Los Gatos mine

VACON® 1000 MV drives power deep pumping at Los Gatos mineMEXICO: Faced with the challenge of pumping stagnant water from depths of more than 400 meters, the Cerro Los Gatos mine opted for medium-voltage variable speed pump control using the VACON® 1000 drive from Danfoss. Drives were delivered and installed in the record time of 14 weeks from factory acceptance test.

-

if (isSmallPicture) {

Cement Plant Realizes Solid Energy Savings with Variable Frequency Drives

Cement Plant Realizes Solid Energy Savings with Variable Frequency DrivesHolcim (US) engaged Danfoss for advanced variable frequency drive technology to assist in making its manufacturing site one of the most energy-efficient cement plants in the world.

-

if (isSmallPicture) {

75% cost reduction in Serbian mining barge

75% cost reduction in Serbian mining bargeReplacing the barge’s diesel engine with an electrical motor controlled by a VLT® AutomationDrive increased reliability and reduced costs.