Simple solutions for minimum maintenance

Airflex expanding clutches and brakes are the go-to solutions for braking and tensioning applications. Available in three different series spanning a range of sizes and features, you’ll find the perfect fit for construction equipment, marine winches, laundry machines and more.

- Long life - Rugged tire-like constricting tube

- Even wear - Force applied uniformly at optimum radius

- Many options - Wide torque capacity range

Three models for braking and tensioning applications

- E – ideal for handling the large thermal loads of medium-speed cyclic applications, but can also serve as a general power transmission

- EB – ideal for applications with light starting loads, EB elements behave as a centrifugal clutch

- ER – thrive in applications that require disconnection without stopping the prime move and when the driving/driven equipment must be frequently withdrawn

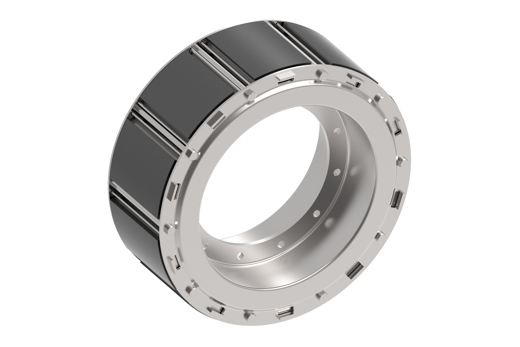

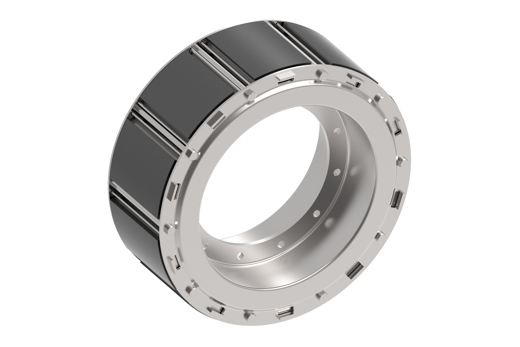

How constricting elements work

Airflex expanding drum clutch and brake elements use a rugged, tire-like neoprene and cord tube that expands radially outward when pressurized. The expansion forces a friction surface against an inner cylindrical drum to create torque..

Force applied at maximum radius from axis

Instead of the reduced radius that occurs in plate clutches, expanding clutches concentrate the frictional force on the inside drum diameter to achieve maximum torque. The radius acts as the torque lever arm to generate and apply force uniformly around the circumference.

Features and benefits

Uniform contact velocity

In Airflex expanding clutches and brakes, friction shoe contact occurs across the cylindrical surface of the drum where the contact velocity is constant. This is an advantage over plate-type clutches where the contact velocity varies across the friction plate face.

Fast and continuous heat dissipation

Heat generated at the inner drum surface quickly travels to the drum's exposed outer surface area where it dissipates by radiation and convection. This feature is ideal for slip clutch and tension brake applications where heat needs to be continuously dissipated.

Self-adjusting to compensate for wear

As friction surfaces wear, the tube simply expands farther as needed. Normal wear does not reduce torque capacity.

No lubrication required

Expanding clutches and brakes do not need lubrication because they lack close-fitting sliding components.

Operates in any plane

Unlike plate clutches that operate best in a vertical plane, an expanding design combined with its centrifugal effects allows for clutch operation in any plane.

Product range

E series

- Expanding centrifugal clutch

- Allows for dual element assemblies

- Provides excellent slip clutch service when coupled with an air-agitating, ventilated drum

- Reinforced spring slots accommodate large spring force

- Split side housings simplify maintenance in applications with limited axial access

- Torque capacities up to 274,000 lb•in (31,000 N•m)

- Available in 10 sizes

EB series

- Expanding centrifugal clutch

- Ideal for light starting loads

- Torque capacities up to 45,000 lb•in (5,090 N•m)

- Available in 11 sizes

ER series

- Large torque in a small package

- Expanding centrifugal clutch

- Torque capacities up to 83,500 lb•in (9,440 N•m)

- Available in 10 sizes

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | Airflex® Industrial Clutch and Brake Product and Application Overview | English | Multiple | 30 Mar, 2023 | 1.4 MB |