Micro Plate™ technology - ideal for district energy solutions and for use in heat pumps and chillers

The next step in application-focused, high-performance heat exchanger design, Micro Plates™ are a revolutionary technology, specially created for district energy solutions and for use in heat pumps, chillers, and close control systems for cooling capacities up 800 kW / 225 TR.

Their innovative plate design optimizes heat transfer whether in your condenser or evaporator with high reliability to achieve increased efficiency with a reduced refrigerant charge.

What does that mean for you?

Our heat exchangers with the new state-of-the art Micro Plate™ technology feature next-generation efficiency and performance – giving you more from your district heating and cooling applications.

Characterized by their unique pattern, our innovative new plates outperform everything else in their class with significantly lower pressure drop and vastly

improved heat transfer.

Our heat exchangers are suitable for virtually every district heating and cooling application and network. Whether your system has varying or constant pressure, large temperature swings, or even an untreated water supply, we have the perfect solution for you.

Features and benefits of Micro Plates™

High efficiency and a longer lifespan help to reduce waste, all of which results in significant savings and a lower carbon footprint.

Micro Plates™ make optimal use of their surface area by allowing water to flow more evenly. This distributes and mixes the media better for maximum heat transfer.

We create individually tailored heat exchangers that meet your requirements. By varying the number, size and placement of dimples, Micro Plates™ can be adapted for optimal heat transfer and minimal pressure drop.

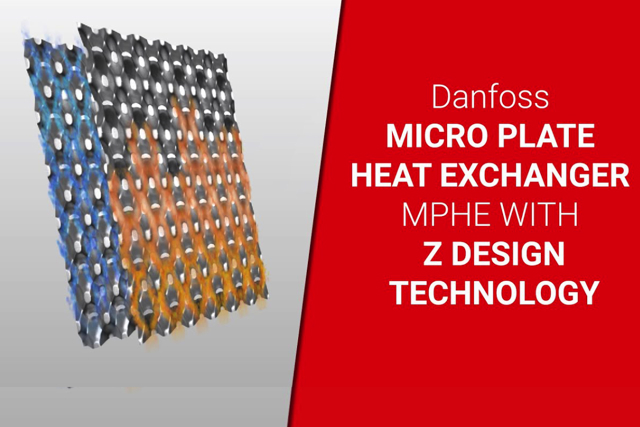

MPHE Z-design range of Micro Plate Heat Exchangers

Unleash the benefits of patented Danfoss Micro Plate technology in your chiller applications with high density refrigerants (R32, R410A, R454B) in capacity range from few kW up to 800 kW.

Innovative plate design optimizes heat transfer in the Micro Plate™ heat exchangers

The Micro Plate Heat Exchanger (MPHE) is ideal for use in heat pumps, chillers, and close control systems for cooling capacities up 800 kW / 225 TR. Their innovative plate design optimizes heat transfer whether in your condenser or evaporator with high reliability to achieve increased efficiency with a reduced refrigerant charge.

Our newest innovation, Z-design Micro Plate Heat Exchangers, are higher efficiency evaporators. They feature dimple-design plates, which provide an asymmetrical refrigerant circulation in a Z-shape pattern to optimize the surface area and therefore increase the heat transfer.

Learn more about the Z-design pattern and benefits

Generation Z – a game changer

Whether Z stands for zero, or for the Z flow pattern of fluids across the heat exchanger plate, all of these are relevant. Using these heat exchangers, HVAC-R manufacturers can achieve significantly better economic and environmental performance with high efficiency.

The secret is in the asymmetric Z-shaped flow. A completely rethought plate pattern pushes the performance of your evaporator to the limits. At the same time, they help achieve a highly stable evaporation process, made possible to reduce refrigerant volume and use less raw material in the heat exchanger’s construction.

The new series employs a dimple-based design, which promotes an asymmetric Z shaped flow of fluid across the plates. Not only does this maximize the heat transfer surface, but the liquid and vapor phases of the refrigerant also remain well mixed, ensuring even thermal contact with the water side of the system. The same heat transfer capacity can therefore be achieved with fewer plates, which reduces both raw material needs and product weight. With each new generation of heat exchanger, Danfoss has improved efficiency. This latest step sets out to disrupt the industry status quo with 20% more efficient heat transfer, 20% lower refrigerant charge and 20% lower raw material weight. All these goals have been achieved and in some cases exceeded with the Z- design evaporators for chiller and heat pump applications.

Generation Z heat exchangers for evaporator in chillers, heat pumps and other refrigeration applications enables the creation of a new generations of systems for new constructions or renovation projects.

View the 3D models:

MPHE with Z design

MPHE dual circuit with Z design

MPHE Double Wall

Features and benefits of the Z-design pattern

Compact design, 30% less weight *

20 percent reduced refrigerant charge*

40 percent higher heat transfer*

Compatible with several refrigerant options

*Z pattern design performance, under same conditions and compared to non-Z design pattern MPHE

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | Z-design MPHEs for chillers Economic and environmental savings in cooling | Chinese (CN) | Multiple | 12 May, 2016 | 21.6 MB | |

| Brochure | Z-design MPHEs for chillers Economic and environmental savings in cooling | English | Multiple | 23 Mar, 2023 | 2.4 MB |