Get even more drive in your HVAC – with rock-bottom lifecycle costs in any climate

More than ever, the extreme climates, inaccessible machine rooms and isolated outposts of our planet need the best process control there is for their HVAC installations. Your everyday critical functions and costly systems need it too, as they face ever-increasing competition and efficiency demands. Always with high performance in mind, the enhanced VLT® HVAC Drive gives you more room to maneuver. It confronts the issues and gives you rock-solid reliability. With rock-bottom lifecycle costs too.

The AHRI Certified™ VLT® HVAC Drive is designed to bring optimized process control to all heating, ventilation and air conditioning (HVAC) applications. Easy to use and with built-in intelligence, the drive is fast and cost-effective to commission. It features a wide range of functions specifically developed for use with pumps, fans, and compressors to save energy, meet environmental regulations and reduce costs in modern buildings.

The compact design of the VLT® HVAC Drive and its efficient heat management system mean it is ideal for applications where drive space is restricted. A selection of safety features, such as Safe Torque Off and Safe Maximum Speed, protect both applications and their operators.

Maximum uptime is ensured as this robust drive offers problem-free operation in harsh environments. Enclosures are available up to IP 66 (depending on the model). And a special coating is available as an option to provide extra protection for circuit boards. Integrated DC chokes and RFI filters safeguard installations by minimizing harmonic distortion and electromagnetic interference.

Supply voltages and power range

- 3 x 200-240 V...1.1-45 kW

- 3 x 380-480 V...1.1-1000 kW

- 3 x 525-600 V...1.1-90 kW

- 3 x 525-690 V...1.1-1400 kW

Low harmonic drive

- 3 x 380-480 V...160-710 kW

12-pulse drive

- 3 x 380-500 V...315-1000 kW

- 3 x 525-690 V...450-1400 kW

Features and benefits

There’s no need for external cooling or oversizing as the maximum ambient temperature is 50°C without derating

PLC capacity is often unnecessary thanks to the Smart Logic Controller

A low initial investment and easy upgrades are possible thanks to the modular concept with a wide range of options

The need for external control and conversion equipment is avoided due to integrated pump, fan and compressor functionality

5–15% energy is saved as a result of the Automatic Energy Optimization function

Less gateway solutions are needed thanks to a wide range of HVAC protocols for building management system controller connectivity

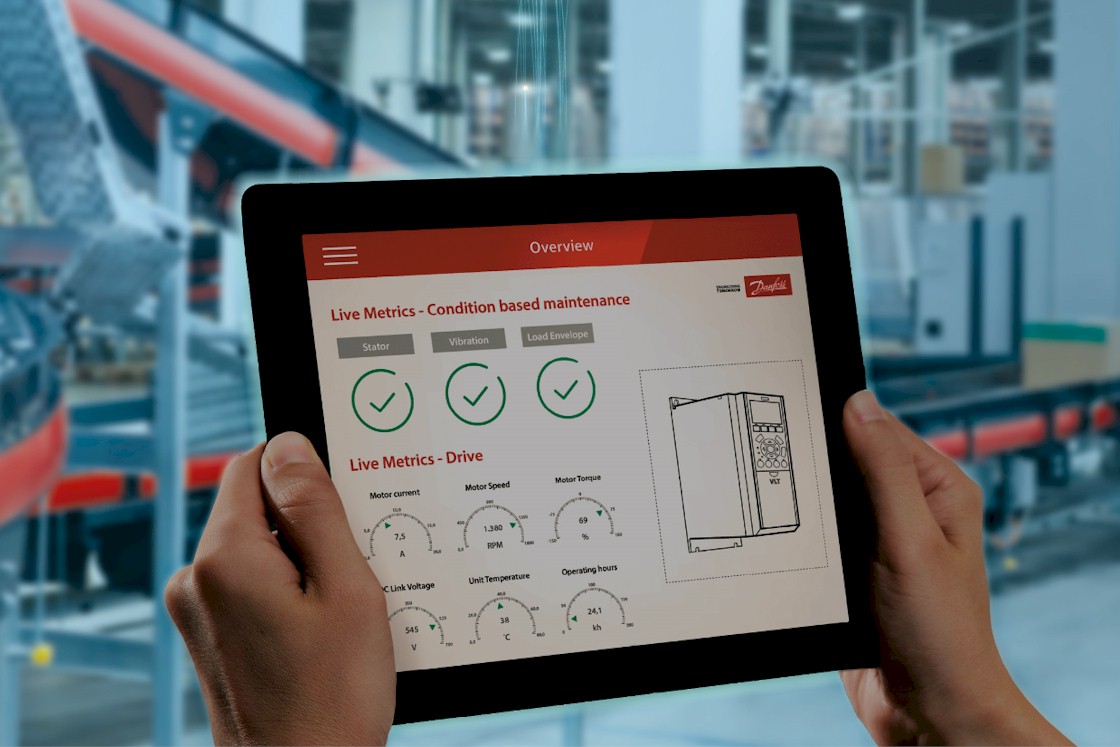

Avoid unplanned downtime with condition based monitoring

Unplanned downtime of HVAC systems can be catastrophic for essential infrastructure and those who depend on it today. Danfoss technologies empower frontline operators - both on site and remote - to predict unforeseen early failures thereby better planning for maintenance and maximizing uptime. Explore how intelligent VLT® drives solve potentially critical problems in HVAC applications.

New application paper: VLT HVAC Drive FC 102 with Fire Emergency Mode

The FC 102 is not only the most efficient of HVAC drives. It also saves lives and protects inventory, by ensuring the most effective smoke control in the event of a fire. With this new application paper, we aim to win more projects by informing customers of special FC 102 features which ensure exceptional performance, when safety is a critical factor.

Safeguard your investment

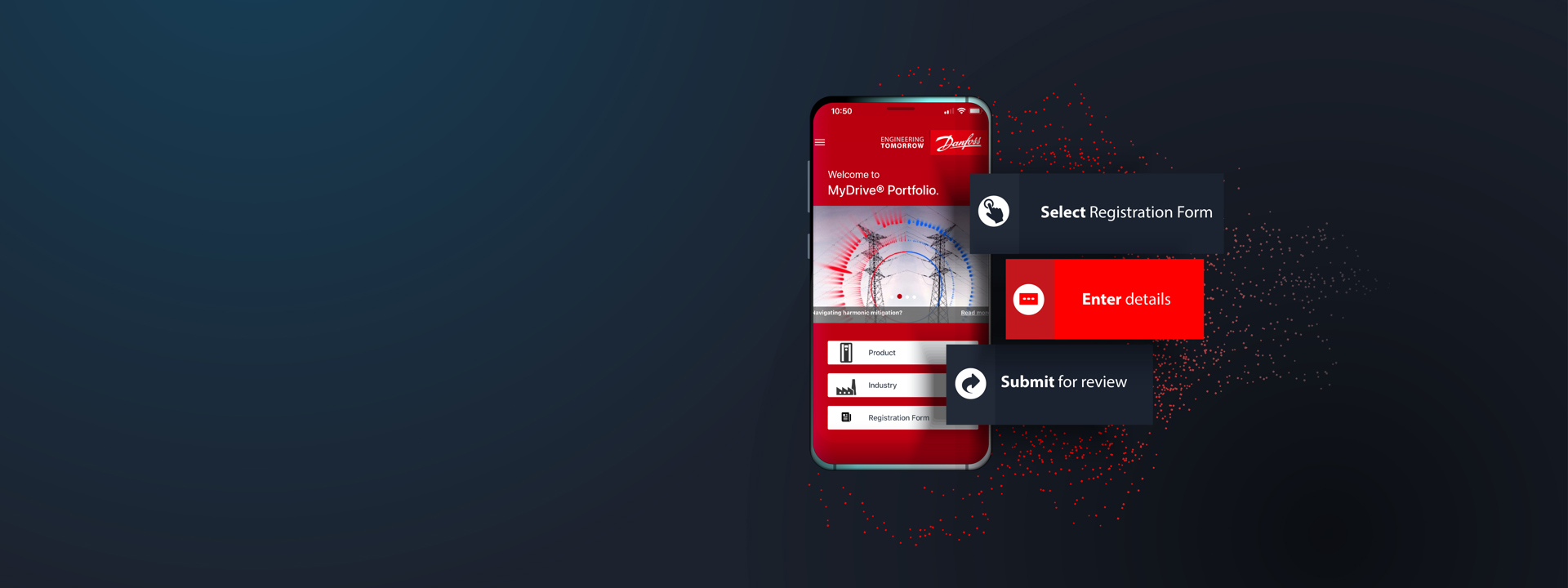

Register your drive and see if you qualify for a 12 month warranty extension.

Offer only available in the United States and Canada.

Documents

HVAC Selection Guide

Find all the information you need regarding the HVAC Drive family

VLT® HVAC Drive literature

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | 9 Tips towards energy efficiency | English | Multiple | 09 Jan, 2023 | 79.2 MB | |

| Brochure | 9 Tips towards energy efficiency - English US | English | United States | 14 Jun, 2023 | 77.8 MB | |

| Case story | Aarhus University Hospital - Skejby Sygehus | English | Multiple | 06 Jun, 2023 | 2.1 MB | |

| Operating guide | Add-On Instr VLT EtherNet-IP MCA 121 | English | Multiple | 15 Feb, 2017 | 1.1 MB | |

| Case story | AEL | English | Multiple | 20 Mar, 2023 | 2.1 MB | |

| Brochure | AOX-ILK Technical Report | Investigation into fan system energy efficiency | English | Multiple | 29 Aug, 2023 | 6.7 MB | |

| Operating guide | BACnet MS-TP Communication w. MBS UBR-01 | English | Multiple | 15 May, 2017 | 1.3 MB | |

| Case story | Carlsberg | English | Multiple | 25 Jun, 2024 | 7.4 MB | |

| Case story | Chester Zoo | English | Multiple | 19 Jul, 2023 | 1.8 MB | |

| Case story | Cityringen Copenhagen | English | Multiple | 16 Mar, 2023 | 4.8 MB | |

| Case story | Cofely Innsbruck | English | Multiple | 17 Aug, 2022 | 2.7 MB | |

| Case story | COP26 | English | Multiple | 01 Sep, 2022 | 3.1 MB | |

| Case story | CPH Energy District Cooling - 2014 | English | Multiple | 06 Feb, 2023 | 1.6 MB | |

| Case story | CPH Energy District Cooling - 2018 | English | Multiple | 06 Feb, 2023 | 1.6 MB | |

| Case story | Crowne Plaza Hotel - 2016 | English | Multiple | 03 May, 2023 | 1.8 MB | |

| Case story | Crowne Plaza Hotel - 2017 | English | Multiple | 23 Aug, 2022 | 750.4 KB | |

| Case story | Crowne Plaza Hotel - 2018 | English | Multiple | 22 Aug, 2022 | 4.1 MB | |

| Brochure | Danfoss Drives Fieldbus Solutions | English | Multiple | 12 Nov, 2021 | 7.7 MB | |

| Brochure | DrivePro® Services Overview | English | Multiple | 03 Feb, 2025 | 26.8 MB | |

| Brochure | DrivePro® Services Overview - US English | English | United States | 03 Feb, 2025 | 26.6 MB | |

| Application guide | Encoder-less Safety using DOLD Module | English | Multiple | 15 Apr, 2017 | 5.9 MB | |

| Case story | Equinix Data Center | English | Multiple | 22 Aug, 2022 | 6.9 MB | |

| Fact sheet | Extended functionality and real LHD for high-performance operation | English | Multiple | 18 Jul, 2023 | 1.4 MB | |

| Fact sheet | Fact Sheet - VLT® Wireless Communication Panel LCP 103 Wireless connectivity to your drive | English | Multiple | 07 Mar, 2023 | 1.4 MB | |

| Application guide | Fire Emergency Mode | English | Multiple | 15 Feb, 2022 | 4.7 MB | |

| Case story | Fly Experience | English | Multiple | 26 Jul, 2022 | 4.0 MB | |

| Case story | Freddo and Co | English | Multiple | 20 Mar, 2023 | 6.0 MB | |

| Case story | Fugloeyhav | English | Multiple | 22 Mar, 2023 | 2.5 MB | |

| Brochure | Harmonics in HVAC | English | Multiple | 12 Jun, 2023 | 19.7 MB | |

| Brochure | Harmonics in HVAC | US English | English | United States | 15 Jun, 2023 | 19.3 MB | |

| Case story | Heat Recovery DN | English | Multiple | 22 Aug, 2022 | 4.5 MB | |

| Case story | Hjoerring Multi Biofuel | English | Multiple | 03 May, 2023 | 4.3 MB | |

| Case story | Hotel Alsik DK | English | Multiple | 10 Aug, 2022 | 3.5 MB | |

| Case story | Hotel Alsik DK - Mobile case | English | Multiple | 22 Nov, 2021 | 4.2 MB | |

| Case story | Hotel Alsik DK - Short case | English | Multiple | 11 May, 2022 | 6.2 MB | |

| Brochure | HVAC & Refrigeration applications - Engineering Guide | English | Multiple | 17 Apr, 2023 | 14.7 MB | |

| Operating guide | IM Vertical Bypass Manual | English | United States | 15 Mar, 2020 | 6.7 MB | |

| Case story | Innsbruck University Clinic | English | Multiple | 19 Jul, 2023 | 3.9 MB | |

| Fact sheet | IP 66/Type 4x enclosed VLT® drives up to 90 kW | English | Multiple | 11 Aug, 2023 | 888.9 KB | |

| Case story | Keppel Bay Tower - Full case | English | Multiple | 18 May, 2023 | 13.0 MB | |

| Case story | Keppel Bay Tower - Short case | English | Multiple | 31 Jan, 2023 | 2.2 MB | |

| Case story | Kleventa Cuppers - English | English | Multiple | 28 Jul, 2022 | 2.8 MB | |

| Case story | Metro de Doha | English | Multiple | 30 Aug, 2022 | 4.1 MB | |

| Case story | Micheville Tunnel | English | Multiple | 25 Aug, 2022 | 2.3 MB | |

| Brochure | Motor technologies | English | Multiple | 19 Nov, 2021 | 7.5 MB | |

| Fact sheet | Mount your drive where you want to...not where you have to | English | United States | 13 Jun, 2023 | 2.7 MB | |

| Fact sheet | Mount your drive where you want to...not where you have to | English | Multiple | 13 Jun, 2023 | 2.9 MB | |

| Case story | MS Cinderella | English | Multiple | 30 Aug, 2022 | 9.3 MB | |

| Case story | MV Island Performer Ulstein | English | Multiple | 16 Mar, 2023 | 3.1 MB | |

| Fact sheet | Panel through mount accessory | English | Multiple | 08 Aug, 2023 | 1.1 MB | |

| Case story | Pharma CBM - Full case | English | Multiple | 14 Feb, 2022 | 2.2 MB | |

| Case story | Pharma CBM - Mobile case | English | Multiple | 14 Feb, 2022 | 690.9 KB | |

| Case story | Pharma CBM - Short case | English | Multiple | 14 Feb, 2022 | 572.3 KB | |

| Case story | Randers Rainforest | English | Multiple | 06 Jun, 2023 | 2.3 MB | |

| Fact sheet | Reduce energy costs with intelligent heat management | English | United States | 19 Jul, 2023 | 1.2 MB | |

| Brochure | Reliable air-handling drives for clean-room applications | English | Multiple | 19 Nov, 2021 | 15.4 MB | |

| Fact sheet | Remote LCP holder - English | English | Multiple | 09 Feb, 2023 | 630.1 KB | |

| Operating guide | Safe Torque Off | English | Multiple | 14 Dec, 2022 | 501.0 KB | |

| Case story | Sellero Tunnel | English | Multiple | 19 Jul, 2023 | 1.3 MB | |

| Brochure | Singapore Green Mark 2021 | English | Singapore | 04 Mar, 2022 | 6.7 MB | |

| Brochure | Systematic energy saving EC+ is the smart trend in HVAC drive technology | English | Multiple | 16 Mar, 2023 | 4.1 MB | |

| Case story | TechnoAlpin 2019 | English | Multiple | 21 Mar, 2023 | 7.0 MB | |

| Brochure | Ten things you need to know about Ecodesign | English | Multiple | 27 Feb, 2023 | 574.9 KB | |

| Case story | Tubingen EyeClinic | English | Multiple | 30 Aug, 2022 | 3.2 MB | |

| Case story | US Steel Tower - US English | English | United States | 03 May, 2023 | 5.0 MB | |

| Case story | Van Asten | English | Multiple | 22 Mar, 2023 | 19.9 MB | |

| Operating guide | VLT ® Modbus RTU | English | Multiple | 28 Oct, 2011 | 1.5 MB | |

| White paper | VLT drives with integrated CBM | English | Multiple | 24 Jun, 2024 | 13.3 MB | |

| Application guide | VLT drives with integrated CBM | English | Multiple | 15 May, 2022 | 1.2 MB | |

| Application guide | VLT HVAC Drive Applications Note | English | Multiple | 30 Apr, 2008 | 6.1 MB | |

| White paper | VLT HVAC Drive FC 102 - Fire Emergency Mode | English | Multiple | 13 Jun, 2023 | 12.9 MB | |

| Operating guide | VLT HVAC Drive FC 102 110-800kW Op.Guide | English | Multiple | 15 Feb, 2022 | 23.0 MB | |

| Operating guide | VLT HVAC Drive FC 102 Low Harmonic Drive | English | United States | 16 Oct, 2009 | 7.3 MB | |

| Brochure | VLT HVAC Drive FC 102 Selection Guide | English | Multiple | 24 Mar, 2025 | 60.9 MB | |

| Brochure | VLT HVAC Drive FC 102 Selection Guide - US English | English | United States | 24 Feb, 2023 | 64.8 MB | |

| Fact sheet | VLT® 12-pulse drive | English | Multiple | 19 Jul, 2023 | 1.5 MB | |

| Design guide | VLT® Advanced Harmonic Filter AHF005-010 | English | Multiple | 15 Feb, 2022 | 6.2 MB | |

| Operating guide | VLT® AKD 102 Drive 110–250 kW | English | Multiple | 15 Jun, 2009 | 9.7 MB | |

| Fact sheet | VLT® BACnet MCA 109 | English | Multiple | 09 Aug, 2023 | 813.9 KB | |

| Fact sheet | VLT® BACnet/IP MCA 125 | English | Multiple | 09 Aug, 2023 | 293.9 KB | |

| Design guide | VLT® Brake Resistor MCE 101 | English | Multiple | 08 May, 2014 | 8.5 MB | |

| Fact sheet | VLT® DeviceNet MCA 104 | English | Multiple | 09 Aug, 2023 | 985.8 KB | |

| Operating guide | VLT® DeviceNet MCA 104 | English | Multiple | 27 Mar, 2015 | 3.5 MB | |

| Fact sheet | VLT® drive with enclosure size D - English | English | Multiple | 07 Feb, 2023 | 474.0 KB | |

| Fact sheet | VLT® drive with enclosure size E - English | English | Multiple | 24 Jan, 2023 | 551.8 KB | |

| Fact sheet | VLT® drive with enclosure size E - US English | English | United States | 25 Jan, 2023 | 531.1 KB | |

| Application guide | VLT® Drives Motor overload protection | English | Multiple | 19 Aug, 2008 | 212.6 KB | |

| Fact sheet | VLT® EtherNet/IP MCA 121 | English | Multiple | 09 Aug, 2023 | 635.4 KB | |

| Operating guide | VLT® FC Series Option Panel | English | United States | 15 Nov, 2012 | 3.2 MB | |

| Operating guide | VLT® FC Series Option Panel | English | Multiple | 14 Nov, 2012 | 4.3 MB | |

| Design guide | VLT® FC Series Output Filter Design G. | English | Multiple | 22 Feb, 2011 | 4.8 MB | |

| Brochure | VLT® Functional Safety | English | Multiple | 12 Nov, 2021 | 2.7 MB | |

| Operating guide | VLT® HVAC Drive BACnet | English | Multiple | 24 Aug, 2009 | 2.0 MB | |

| Programming guide | VLT® HVAC Drive FC 102 | English | Multiple | 18 Oct, 2024 | 7.1 MB | |

| Fact sheet | VLT® HVAC Drive FC 102 | English | Multiple | 31 Aug, 2022 | 314.3 KB | |

| Fact sheet | VLT® HVAC Drive FC 102 - US English | English | United States | 09 Sep, 2024 | 216.5 KB | |

| Design guide | VLT® HVAC Drive FC 102 1.1-90 kW | English | Multiple | 09 Oct, 2023 | 3.8 MB | |

| Design guide | VLT® HVAC Drive FC 102 1.1-90 kW | English | United States | 13 Jun, 2014 | 7.4 MB | |

| Operating guide | VLT® HVAC Drive FC 102 110-400kW D-frame | English | Multiple | 15 Jan, 2022 | 13.0 MB | |

| Operating guide | VLT® HVAC Drive FC 102 110-400kW D-frame | English | United States | 15 Feb, 2012 | 4.8 MB | |

| Design guide | VLT® HVAC Drive FC 102 110–800 kW D and E | English | United States | 15 Jan, 2018 | 14.7 MB | |

| Design guide | VLT® HVAC Drive FC 102 110–800 kW D and E | English | Multiple | 15 Jan, 2018 | 14.3 MB | |

| Operating guide | VLT® HVAC Drive FC 102 315-1400 kW | English | United States | 27 Mar, 2015 | 4.8 MB | |

| Operating guide | VLT® HVAC Drive FC 102 315-1400 kW | English | Multiple | 12 Aug, 2014 | 4.6 MB | |

| Design guide | VLT® HVAC Drive FC 102 355-1400 kW | English | United States | 15 Nov, 2017 | 12.3 MB | |

| Design guide | VLT® HVAC Drive FC 102 355-1400 kW | English | Multiple | 15 Nov, 2017 | 7.7 MB | |

| Operating guide | VLT® HVAC Drive FC 102 FLN | English | Multiple | 22 Dec, 2008 | 412.2 KB | |

| Operating guide | VLT® HVAC Drive FC 102 LonWorks | English | Multiple | 11 Nov, 2008 | 2.2 MB | |

| Operating guide | VLT® HVAC Drive FC 102 Low Harm. Drive | English | Multiple | 15 Jan, 2022 | 22.1 MB | |

| Operating guide | VLT® HVAC Drive FC 102 Low Harm. Drive | English | United States | 13 Aug, 2015 | 17.6 MB | |

| Operating guide | VLT® HVAC Drive FC 102 Native BACnet | English | Multiple | 20 Sep, 2010 | 1.3 MB | |

| Application guide | VLT® HVAC Drive FC 102 Temp. Derating | English | Multiple | 20 Aug, 2008 | 981.5 KB | |

| Fact sheet | VLT® HVAC Drive FC 102_Condition-based monitoring functions - US English | English | United States | 07 Feb, 2023 | 2.0 MB | |

| Operating guide | VLT® HVAC Drive FC 102, 1.1-90 kW | English | Multiple | 28 Sep, 2023 | 7.1 MB | |

| Operating guide | VLT® HVAC Drive FC 102, 12 Pulse | English | Multiple | 15 Jan, 2022 | 5.4 MB | |

| Operating guide | VLT® HVAC Drive FC 102, 355-800 kW, Encl | English | Multiple | 15 Feb, 2022 | 19.3 MB | |

| Application guide | VLT® HVAC Drive in Fan Application with | English | Multiple | 10 Feb, 2011 | 41.3 KB | |

| Programming guide | VLT® HVAC Drive Programming Guide V3.3x | English | United States | 30 May, 2025 | 9.0 MB | |

| Fact sheet | VLT® Low Harmonic Drive | English | Multiple | 19 Jul, 2023 | 673.1 KB | |

| Operating guide | VLT® Metasys N2 FC 102 and FC 202 series | English | Multiple | 12 Feb, 2010 | 552.8 KB | |

| Fact sheet | VLT® Modbus TCP MCA 122 | English | Multiple | 09 Aug, 2023 | 818.2 KB | |

| Operating guide | VLT® Modbus TCP MCA 122 | English | Multiple | 02 May, 2013 | 3.4 MB | |

| Fact sheet | VLT® Parallel Drive Modules | English | Multiple | 11 Aug, 2023 | 446.0 KB | |

| Operating guide | VLT® Parallel Drive Modules 250-1200 kW | English | Multiple | 04 Aug, 2017 | 8.5 MB | |

| Design guide | VLT® Parallel Drive Modules, 250–1200 kW | English | Multiple | 15 Aug, 2017 | 16.4 MB | |

| Fact sheet | VLT® Pressure Transmitter PTU 025 Filter Monitoring - English | English | Multiple | 07 Feb, 2023 | 739.0 KB | |

| Fact sheet | VLT® PROFINET MCA 120 | English | Multiple | 09 Aug, 2023 | 663.4 KB | |

| Fact sheet | VLT® PTC Thermistor Card MCB 112 | English | Multiple | 09 Aug, 2023 | 693.8 KB | |

| Operating guide | VLT® PTC Thermistor Card MCB 112 | German; English | Multiple | 19 Dec, 2023 | 3.0 MB | |

| Operating guide | VLT® PTC Thermistor Card MCB 112 | English | Multiple | 15 Jul, 2024 | 1.2 MB | |

| Brochure | VLT® Pump Control OEM | English | Multiple | 22 Nov, 2021 | 15.1 MB | |

| Fact sheet | VLT® Real-time Clock MCB 117 | Advanced data logging by time stamping | English | Multiple | 26 Apr, 2023 | 288.1 KB | |

| Case story | Volkswagen Novenco | English | Multiple | 30 Aug, 2022 | 6.5 MB | |

| Case story | VSS Glassfiber Latvia | English | Multiple | 16 Jun, 2022 | 10.9 MB |

Related applications

Pumps, fans, compressors.

-

if (isSmallPicture) {

Drives for commercial compressors

Drives for commercial compressorsVariable speed control with AC drives enables you to reduce energy consumption by running compressor applications at a lower speed.

-

if (isSmallPicture) {

Drives for compressors in residential buildings

Drives for compressors in residential buildingsVariable speed control of a chiller allows you to provide constant pressure regulation while matching the capacity to the actual need based on measurements in the system. Speed control is beneficial when a compressor runs for long periods at partial load. Reduce operational costs by running applications at a lower speed which reduces energy consumption. And reduce installation costs by optimizing the system and the compressor itself.

-

if (isSmallPicture) {

Drives for fans in commercial buildings

Drives for fans in commercial buildingsWith user-friendly interfaces, distributed intelligence and reduced power consumption, Danfoss AC drives optimize the performance of fans.

-

if (isSmallPicture) {

Drives for fans in residential buildings

Drives for fans in residential buildingsWith user-friendly interfaces, distributed intelligence and reduced power consumption, Danfoss AC drives optimize the performance of fans.

-

if (isSmallPicture) {

Drives for pumps in commercial buildings

Drives for pumps in commercial buildingsProtect your pump and optimize commercial ventilation and air conditioning performance using AC drives.

Case studies

-

if (isSmallPicture) {

Pumping smarter, not harder with intelligent drives for maximized indoor comfort

Pumping smarter, not harder with intelligent drives for maximized indoor comfortUSA: With integrated condition monitoring, VLT® HVAC Drive FC 102 optimizes hydronic system uptime to enhance indoor climate at a community healthcare facility in Wisconsin.

-

if (isSmallPicture) {

How did this smart factory reach carbon-neutral?

How did this smart factory reach carbon-neutral?POLAND: The new Danfoss production hall in Grodzisk Mazowiecki has reached carbon-neutrality, thanks to full electrification, energy-saving solutions such as Danfoss drives, and energy from renewable sources.

-

if (isSmallPicture) {

How does Beat the Storm deliver more fun for 80% less CO2?

How does Beat the Storm deliver more fun for 80% less CO2?DENMARK: Universe Science Park saves 80% on emissions and the power bill for its wind tunnel attraction “Beat the Storm”, with the intelligent VLT® HVAC drive.

-

if (isSmallPicture) {

Drives secure fresh air inside South America’s tallest building

Drives secure fresh air inside South America’s tallest buildingA huge number of Danfoss drives secure comfortable temperatures and cut down energy use inside Chile’s famous Costanera Center.

-

if (isSmallPicture) {

Danfoss ensures sustainable luxury in the heart of Sønderborg

Danfoss ensures sustainable luxury in the heart of SønderborgDENMARK: Hotel Alsik is proud to be 76% CO2-neutral, with sustainable solutions reflected throughout the entirety of this magnificent hotel – from the energy-efficient solutions in the hotel rooms, the design of the building and the power supply, to the 380 m2 solar cells on the roof.

-

if (isSmallPicture) {

Convention Center Exhibits Major Pump Energy Savings

Convention Center Exhibits Major Pump Energy SavingsDanfoss Drives VFD retrofit project helped the one million square foot Enercare Centre in Toronto, Canada save energy with dramatically improved pump motor efficiency, cut electricity costs, and helped achieve the center's sustainability goals.

Learning

News

-

if (isSmallPicture) {

Harmonic mitigation reduces filter power loss by 60%Tuesday, January 17, 2023

Harmonic mitigation reduces filter power loss by 60%Tuesday, January 17, 2023With 60% lower power losses compared to similar filters, Danfoss Advanced Active Filter AAF 007 can rescue your energy budget. Enjoy harmonic mitigation, power factor correction and imbalance compensation, all in one product. This filter is compatible for use with any drive from the entire Danfoss product portfolio.

-

if (isSmallPicture) {

New application paper: VLT HVAC Drive FC 102 with Fire Emergency ModeMonday, January 10, 2022

New application paper: VLT HVAC Drive FC 102 with Fire Emergency ModeMonday, January 10, 2022The FC 102 is not only the most efficient of HVAC drives. It also saves lives and protects inventory, by ensuring the most effective smoke control in the event of a fire. With this new application paper, we aim to win more projects by informing customers of special FC 102 features which ensure exceptional performance, when safety is a critical factor.

-

if (isSmallPicture) {

Unlock new features in your VLT® drives with license keyMonday, August 2, 2021

Unlock new features in your VLT® drives with license keyMonday, August 2, 2021Tailor your drives to suit your application by unlocking licensed features. Fast plug-and-play activation will let you create the best conditions for your business.

Software

| Type | Software Characteristic | Name | Version | Language | Released | Status | Download | File type |

|---|---|---|---|---|---|---|---|---|

| Software tools | SISTEMA Library for Danfoss Drives | 1.07 | English | 17 Jan, 2025 | Released | 385.9 KB | .zip | |

| System software | Library | VLT® AOI for Rockwell Studio 5000 | 1.00 | English | 17 Dec, 2019 | Released | 7.2 MB | .zip |

| System software | Fieldbus configuration file | VLT® Drives DeviceNet EDS | 01 | English | 31 May, 2021 | Released | 2.2 MB | .zip |

| System software | Fieldbus configuration file | VLT® Drives EtherNet/IP EDS | 02 | English | 27 Jun, 2016 | Released | 59.8 KB | .zip |

| System software | Library | VLT® Drives PROFIBUS PCA Block | 01 | English | 19 Mar, 2008 | Released | 465.8 KB | .zip |

| Software tools | VLT® Energy Box | 2.1.0.1 | English | 27 Sep, 2012 | Released | 15.3 MB | .zip | |

| System software | Library | VLT® EtherNet/IP Add-on Instructions | 01 | English | 27 Sep, 2013 | Released | 443.0 KB | .zip |

| System software | Fieldbus configuration file | VLT® HVAC Drive FC 102 LNS Plug-in | 01 | English | 23 Jun, 2008 | Released | 3.7 MB | .zip |

| System software | Fieldbus configuration file | VLT® HVAC Drive FC 102 LonWorks | 01 | English | 13 Mar, 2009 | Released | 97.2 KB | .zip |

| Software tools | VLT® HVAC Drive Simulator | 05.02 | English | 27 Jun, 2017 | Released | 2.9 MB | .zip | |

| System software | Support file | VLT® HVAC Drive Support File | 7.01 | English | 28 Jan, 2022 | Released | 4.5 MB | .zip |

| System software | Library | VLT® Library for B&R Automation | 1.00 | English | 17 Dec, 2019 | Released | 7.1 MB | .zip |

| System software | Library | VLT® Library for TIA Portal | 1.12 | English | 17 Dec, 2019 | Released | 11.9 MB | .zip |

| System software | Library | VLT® Library for TwinCAT 3 | 1.12 | English | 17 Dec, 2019 | Released | 8.4 MB | .zip |

| System software | Library | VLT® Library for Unity Pro | 1.00 | English | 17 Dec, 2019 | Released | 9.7 MB | .zip |

| System software | Fieldbus configuration file | VLT® MCA101 PROFIBUS GSD | 01 | English | 03 Nov, 2010 | Released | 76.9 KB | .zip |

| System software | Fieldbus configuration file | VLT® MCA120 PROFINET GSDML | 01 | English | 21 Feb, 2018 | Released | 719.2 KB | .zip |

| Software tools | VLT® Motion Control Tool MCT10 | 5.50 | English | 14 Jul, 2022 | Released | 944.1 MB | .zip | |

| Software tools | VLT® Motion Control Tool MCT31 | 2.0.4 | English | 17 Oct, 2017 | Released | 25.2 MB | .zip |

Drawings

Frame Ratings by HP

Contact factory for drives larger than 350HP

Additional mechanical drawings including drawings for Drives with options, electrical drawings and E-Plan files are located below this table under the heading 3D models and drawings.

Frame |

Enclosure |

HP Range |

Base drive dimensions (Inches) |

Mechanical drawing # |

|||||||

NEMA 1 |

NEMA 12 |

208V |

460V |

600V |

Height |

Width |

Depth |

T1 |

T2 |

T3 |

|

A2 |

O | 0.5-3 | 0.5-5 | - | 14.6 | 3.5 | 8.1 | 176U8484 | 176U8485 | 176U5288 | |

A3 |

O | 5 | 7.5-10 | 0.5-10 | 5.1 | ||||||

A5 |

O | 0.5-5 | 0.5-10 | 0.5-10 | 16.5 | 9.5 | 7.9 | 176U5289 | 176U5290 | 176U3833 | |

B1 |

O | O | 7.5 - 15 | 15-25 | 18.9 | 9.5 | 10.3 | 176U8471 | 176U8472 | 176U8473 | |

B2 |

O | O | 20 | 30-40 | 25.6 | 176U8474 | 176U8475 | 176U8476 | |||

C1 |

O | O | 25-40 | 50-75 | 26.8 | 12.1 | 12.2 | 176U8477 | 176U8463 | 176U8479 | |

C2 |

O | O | 50-60 | 100-125 | 30.3 | 14.6 | 13.2 | 176U8480 | 176U8481 | 176U8482 | |

D1 |

O | O | - | 150-200 | 150-250 | 45.6 | 16.5 | 14.7 | 176U8435 | ||

D2 |

O | O | 250-350 | 300-350 | 60.6 | ||||||

D1h |

O | O | - | 150-200 | 150-250 | 35.5 | 12.8 | 14.9 | 177R0490 | 174N8666 | |

D2h |

O | O | 250-350 | 300-350 | 43.6 | 16.5 | 176U8480 | ||||

Tier Code Description

- T1 Drive with disconnect or fused disconnect (All frames). T1 drawings are also valid for stand alone drives frame size A5 and larger.

- T2 Drive with bypass or non-bypass panels with contactor motor selection, reactor or dV/dt filter

- T3 Drive with bypass and non-bypass panels with contactor motor selection, reactor or dV/dt filter

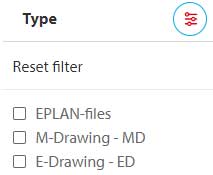

To sort drawings in the 3D models and drawings table below, click on the filter icon to the right of the column title "Type" (shown circled at right):

Can't find the 3D model or drawing you're looking for? Sort and filter the following table by using the icons at the top of the columns.

| Type | Name | Language | Updated | Download | File type |

|---|---|---|---|---|---|

| Eplan drawing | 130B1102_Eplan | 26 Jan, 2025 | 1.0 MB | .zip | |

| Eplan drawing | 130B1106_Eplan | 26 Jan, 2025 | 1.0 MB | .zip | |

| Eplan drawing | 130B1108_Eplan | 27 Jan, 2025 | 2.0 MB | .zip | |

| Eplan drawing | 130B1119_Eplan | 27 Jan, 2025 | 1.1 MB | .zip | |

| Eplan drawing | 130B1120_Eplan | 27 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | 130B1125_Eplan | 27 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | 130B1137_EPlan | 27 Jan, 2025 | 1.0 MB | .zip | |

| Eplan drawing | 130B1143_Eplan | 26 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | 130B1144_Eplan | 27 Jan, 2025 | 1.2 MB | .zip | |

| Eplan drawing | 130B1172_Eplan | 27 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | 130B1196_Eplan | 26 Jan, 2025 | 816.3 KB | .zip | |

| Eplan drawing | 130B1202_Eplan | 26 Jan, 2025 | 1.0 MB | .zip | |

| Eplan drawing | 130B1206_Eplan | 26 Jan, 2025 | 1.0 MB | .zip | |

| Eplan drawing | 130B1208_Eplan | 25 Jan, 2025 | 2.0 MB | .zip | |

| Eplan drawing | 130B1212_Eplan | 27 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | 130B1219_Eplan | 26 Jan, 2025 | 1.1 MB | .zip | |

| Eplan drawing | 130B1220_Eplan | 25 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | 130B1235_Eplan | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | 130B1243-Eplan | 26 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | 130B1244_Eplan | 26 Jan, 2025 | 1.2 MB | .zip | |

| Eplan drawing | 130B1272-Eplan | 26 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | 130B1296_Eplan | 26 Jan, 2025 | 816.2 KB | .zip | |

| Eplan drawing | 131B4207_Eplan | 02 Jun, 2025 | 1.3 MB | .zip | |

| Eplan drawing | 131L0071_Eplan | 02 Jun, 2025 | 1.0 MB | .zip | |

| Eplan drawing | 131Z9686_Eplan | 27 Jan, 2025 | 1.8 MB | .zip | |

| Eplan drawing | 134B1586_Eplan | 27 Jan, 2025 | 1.2 MB | .zip | |

| Eplan drawing | 134F3650_Eplan | 26 Jan, 2025 | 1.9 MB | .zip | |

| Eplan drawing | 134N4225_Eplan | 26 Jan, 2025 | 2.0 MB | .zip | |

| Eplan drawing | 134U4929_Eplan | 03 Jun, 2025 | 1.5 MB | .zip | |

| Eplan drawing | 135U2885_Eplan | 26 Jan, 2025 | 2.0 MB | .zip | |

| Eplan drawing | FC-102N110T4E54H4XGCXXXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 859.0 KB | .zip | |

| Eplan drawing | FC-102N160T4E5MN4TGC7XXSXXXXAXBKCXXXXD0 | 25 Jan, 2025 | 6.8 MB | .zip | |

| Eplan drawing | FC-102N200T4E5MN4TGC7XXSXXXXAXBKCXXXXD0 | 26 Jan, 2025 | 5.8 MB | .zip | |

| Eplan drawing | FC-102N250T4E21H4XGCXXXSXXXXAXBXCXXXXDX | 27 Jan, 2025 | 980.1 KB | .zip | |

| Eplan drawing | FC-102N315T4H54H4XGC3XXSXXXXAXBXCXXXXDX | 25 Jan, 2025 | 881.9 KB | .zip | |

| Eplan drawing | FC-102N560T4E54H4TGC3XXSXXXXA0B4CXXXXD0 | 26 Jan, 2025 | 1.7 MB | .zip | |

| Eplan drawing | FC-102P11KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 1.8 MB | .zip | |

| Eplan drawing | FC-102P11KT4E20H1XXXXXXSXXXXA0BXCXXXXDX | 25 Jan, 2025 | 1.0 MB | .zip | |

| Eplan drawing | FC-102P15KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 1.8 MB | .zip | |

| Eplan drawing | FC-102P15KT4E21H1TGCXXXSXXXXALBXCXXXXD0 | 26 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-102P15KT4E55H1XGXXXXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 2.4 MB | .zip | |

| Eplan drawing | FC-102P18KT4E20H1XGXXXXSXXXXAXBXCXXXXDX | 27 Jan, 2025 | 1.8 MB | .zip | |

| Eplan drawing | FC-102P18KT4E20H1XXXXXXSXXXXA0BXCXXXXDX | 26 Jan, 2025 | 1.0 MB | .zip | |

| Eplan drawing | FC-102P1M2T7E21H2XGCXXXSXXXXAXBXCXXXXDX | 25 Jan, 2025 | 2.2 MB | .zip | |

| Eplan drawing | FC-102P22KT4E21H1TGCXXXSXXXXALBXCXXXXD0 | 25 Jan, 2025 | 954.2 KB | .zip | |

| Eplan drawing | FC-102P22KT4E21H1XGXXXXSXXXXAXBKCXXXXDX | 26 Jan, 2025 | 953.8 KB | .zip | |

| Eplan drawing | FC-102P22KT4E21H1XGXXXXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 897.8 KB | .zip | |

| Eplan drawing | FC-102P22KT4E66H3XGXXXXSXXXXAXBXCXXXXDX | 25 Jan, 2025 | 2.0 MB | .zip | |

| Eplan drawing | FC-102P2K2T4E20H1XXXXXXSXXXXA0BXCXXXXDX | 25 Jan, 2025 | 724.0 KB | .zip | |

| Eplan drawing | FC-102P30KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 2.6 MB | .zip | |

| Eplan drawing | FC-102P30KT4E21H1XGX1XXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 721.6 KB | .zip | |

| Eplan drawing | FC-102P30KT4E55H1XGX1XXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 717.9 KB | .zip | |

| Eplan drawing | FC-102P30KT4E55H1XGXXXXSXXXXAXBXCXXXXDX | 25 Jan, 2025 | 1.9 MB | .zip | |

| Eplan drawing | FC-102P37KT4E55H1XGXXXXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-102P3K0T4E20H1XGXXXXSXXXXAXBXCXXXXDX | 25 Jan, 2025 | 1.1 MB | .zip | |

| Eplan drawing | FC-102P45KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 25 Jan, 2025 | 2.1 MB | .zip | |

| Eplan drawing | FC-102P4K0T4Z55H1XGXXOXSXXXXAXBXCXXXXDX | 25 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-102P55KT4E20H2XGXXXXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 1.6 MB | .zip | |

| Eplan drawing | FC-102P560T4E54H2TGC7XKSXXXXA0B4CXXXXD0 | 27 Jan, 2025 | 2.5 MB | .zip | |

| Eplan drawing | FC-102P5K5T4E20H1XXXXXXSXXXXA0BXCXXXXDX | 26 Jan, 2025 | 620.8 KB | .zip | |

| Eplan drawing | FC-102P75KT4E20H2XGCXXXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 1.6 MB | .zip | |

| Eplan drawing | FC-102P75KT4E55H2XGXXXXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-102P7K5T4E20H1XNXXXXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 611.4 KB | .zip | |

| Eplan drawing | FC-102P7K5T4E55H1XGXXXXSXXXXAXBXCXXXXDX | 26 Jan, 2025 | 676.9 KB | .zip | |

| Eplan drawing | FC-102P90KT4E55H2TGXXXXSXXXXA0B0CXXXXD0 | 27 Jan, 2025 | 1.6 MB | .zip | |

| Dimensional drawing | MCAD B2 IP55 w switch | 26 Jan, 2025 | 92.7 MB | .stp | |

| Dimensional drawing | MCAD C1 IP55 w switch | 26 Jan, 2025 | 102.6 MB | .stp | |

| Dimensional drawing | MCAD C1 IP55 wo switch | 26 Jan, 2025 | 100.7 MB | .stp | |

| Dimensional drawing | MCAD EnclDrive 400 mm Gland plate Bottom | 26 Jan, 2025 | 120.3 KB | ||

| Dimensional drawing | MCAD EnclDrive 60 mm Gland plate Bottom | 25 Jan, 2025 | 176.0 KB | ||

| BIM model | MCAD FC 102 A2 IP20 1.1-4kW | 27 Jan, 2025 | 2.8 MB | .zip | |

| BIM model | MCAD FC 102 A2 IP20 AB 1.1-4kW | 25 Jan, 2025 | 2.8 MB | .zip | |

| BIM model | MCAD FC 102 A2 IP20 ABC 1.1-4kW | 27 Jan, 2025 | 2.8 MB | .zip | |

| BIM model | MCAD FC 102 A2 IP21 1.1-4kW | 26 Jan, 2025 | 2.8 MB | .zip | |

| BIM model | MCAD FC 102 A2 IP21 AB-1.1-4kW | 26 Jan, 2025 | 2.8 MB | .zip | |

| BIM model | MCAD FC 102 A3 IP20 1.1-7.5kW | 27 Jan, 2025 | 5.9 MB | .zip | |

| BIM model | MCAD FC 102 A3 IP20 AB 1.1-7.5kW | 26 Jan, 2025 | 5.9 MB | .zip | |

| BIM model | MCAD FC 102 A3 IP20 ABC 1.1-7.5kW | 26 Jan, 2025 | 5.9 MB | .zip | |

| BIM model | MCAD FC 102 A3 IP21 1.1-7.5kW | 26 Jan, 2025 | 5.9 MB | .zip | |

| BIM model | MCAD FC 102 A3 IP21 AB 1.1-7.5kW | 25 Jan, 2025 | 5.9 MB | .zip | |

| BIM model | MCAD FC 102 A4 IP55 1.1-4kW | 26 Jan, 2025 | 2.7 MB | .zip | |

| BIM model | MCAD FC 102 A4 IP66 1.1-4kW | 26 Jan, 2025 | 2.7 MB | .zip | |

| BIM model | MCAD FC 102 A5 IP55 1.1-7.5kW | 25 Jan, 2025 | 8.0 MB | .zip | |

| BIM model | MCAD FC 102 A5 IP66 1.1-7.5kW | 26 Jan, 2025 | 8.0 MB | .zip | |

| BIM model | MCAD FC 102 B1 IP21 5.5-18kW | 26 Jan, 2025 | 2.9 MB | .zip | |

| BIM model | MCAD FC 102 B1 IP55 5.5-18kW | 25 Jan, 2025 | 2.9 MB | .zip | |

| BIM model | MCAD FC 102 B1 IP66 5.5-18kW | 26 Jan, 2025 | 2.9 MB | .zip | |

| BIM model | MCAD FC 102 B2 IP21 11-30kW | 26 Jan, 2025 | 3.2 MB | .zip | |

| BIM model | MCAD FC 102 B2 IP55 11-30kW | 25 Jan, 2025 | 3.2 MB | .zip | |

| BIM model | MCAD FC 102 B2 IP66 15-30kW | 25 Jan, 2025 | 1.7 MB | .zip | |

| BIM model | MCAD FC 102 B3 IP20 5.5-18kW | 27 Jan, 2025 | 3.1 MB | .zip | |

| BIM model | MCAD FC 102 B3 IP20 AB 5.5-18kW | 26 Jan, 2025 | 3.1 MB | .zip | |

| BIM model | MCAD FC 102 B3 IP20 ABC 5.5-18kW | 26 Jan, 2025 | 3.1 MB | .zip | |

| BIM model | MCAD FC 102 B3 IP21 5.5-18kW | 26 Jan, 2025 | 3.1 MB | .zip | |

| BIM model | MCAD FC 102 B3 IP21 AB 5.5-18kW | 26 Jan, 2025 | 3.1 MB | .zip | |

| BIM model | MCAD FC 102 B4 IP20 11-37kW | 26 Jan, 2025 | 4.6 MB | .zip | |

| BIM model | MCAD FC 102 B4 IP21 11-37kW | 25 Jan, 2025 | 4.6 MB | .zip | |

| BIM model | MCAD FC 102 C1 IP21 18-55kW | 26 Jan, 2025 | 2.9 MB | .zip | |

| BIM model | MCAD FC 102 C1 IP55 18-55kW | 26 Jan, 2025 | 2.9 MB | .zip | |

| BIM model | MCAD FC 102 C1 IP66 18-55kW | 26 Jan, 2025 | 2.9 MB | .zip | |

| BIM model | MCAD FC 102 C2 IP21 37-90kW | 26 Jan, 2025 | 3.5 MB | .zip | |

| BIM model | MCAD FC 102 C2 IP55 37-90kW | 27 Jan, 2025 | 3.5 MB | .zip | |

| BIM model | MCAD FC 102 C2 IP66 37-90kW | 26 Jan, 2025 | 2.0 MB | .zip | |

| BIM model | MCAD FC 102 C3 IP20 22-55kW | 27 Jan, 2025 | 2.7 MB | .zip | |

| BIM model | MCAD FC 102 C3 IP21 22-55kW | 26 Jan, 2025 | 2.7 MB | .zip | |

| BIM model | MCAD FC 102 C4 IP20 37-90kW | 25 Jan, 2025 | 2.1 MB | .zip | |

| BIM model | MCAD FC 102 C4 IP21 37-90kW | 26 Jan, 2025 | 2.1 MB | .zip | |

| Dimensional drawing | MCAD FC A2 IP20 | 26 Jan, 2025 | 5.5 MB | .dxf | |

| Dimensional drawing | MCAD FC A2 IP20 A | 26 Jan, 2025 | 1.9 MB | ||

| Dimensional drawing | MCAD FC A2 IP20 A | 25 Jan, 2025 | 2.2 MB | .jpg | |

| Dimensional drawing | MCAD FC A2 IP20 A | 25 Jan, 2025 | 8.6 MB | .stp | |

| Dimensional drawing | MCAD FC A2 IP20 A | 25 Jan, 2025 | 7.2 MB | .dxf | |

| Dimensional drawing | MCAD FC A2 IP20 AB | 25 Jan, 2025 | 2.2 MB | .jpg | |

| Dimensional drawing | MCAD FC A2 IP20 ABC | 25 Jan, 2025 | 2.3 MB | .jpg | |

| Dimensional drawing | MCAD FC A2 IP20 ABC | 26 Jan, 2025 | 9.4 MB | .stp | |

| Dimensional drawing | MCAD FC A2 IP20 AC | 25 Jan, 2025 | 2.0 MB | ||

| Dimensional drawing | MCAD FC A2 IP20 AC | 27 Jan, 2025 | 2.3 MB | .jpg | |

| Dimensional drawing | MCAD FC A2 IP20 AC | 26 Jan, 2025 | 7.8 MB | .dxf | |

| Dimensional drawing | MCAD FC A2 IP20 AC | 26 Jan, 2025 | 9.4 MB | .stp | |

| Dimensional drawing | MCAD FC A2 IP20 B | 25 Jan, 2025 | 1.8 MB | ||

| Dimensional drawing | MCAD FC A2 IP20 B | 25 Jan, 2025 | 5.6 MB | .dxf | |

| Dimensional drawing | MCAD FC A2 IP20 C | 25 Jan, 2025 | 1.9 MB | ||

| Dimensional drawing | MCAD FC A2 IP20 C | 26 Jan, 2025 | 6.0 MB | .dxf | |

| Dimensional drawing | MCAD FC A2 IP20 C | 25 Jan, 2025 | 9.0 MB | .stp | |

| Dimensional drawing | MCAD FC A2 IP20 C | 26 Jan, 2025 | 2.2 MB | .jpg | |

| Dimensional drawing | MCAD FC A2 IP21 | 26 Jan, 2025 | 2.8 MB | .jpg | |

| Dimensional drawing | MCAD FC A2 IP21 B | 26 Jan, 2025 | 2.6 MB | .dxf | |

| Dimensional drawing | MCAD FC A2 IP21 B | 27 Jan, 2025 | 2.8 MB | .jpg | |

| Dimensional drawing | MCAD FC A2 IP21 B | 25 Jan, 2025 | 9.0 MB | .stp | |

| Dimensional drawing | MCAD FC A2 IP21 B | 27 Jan, 2025 | 1.6 MB | ||

| Dimensional drawing | MCAD FC A3 IP20 | 25 Jan, 2025 | 3.8 MB | .dxf | |

| Dimensional drawing | MCAD FC A3 IP20 | 26 Jan, 2025 | 2.2 MB | .jpg | |

| Dimensional drawing | MCAD FC A3 IP20 | 27 Jan, 2025 | 10.3 MB | .stp | |

| Dimensional drawing | MCAD FC A3 IP20 A | 26 Jan, 2025 | 1.7 MB | ||

| Dimensional drawing | MCAD FC A3 IP20 A | 25 Jan, 2025 | 3.7 MB | .dxf | |

| Dimensional drawing | MCAD FC A3 IP20 A | 25 Jan, 2025 | 10.4 MB | .stp | |

| Dimensional drawing | MCAD FC A3 IP20 A | 27 Jan, 2025 | 2.3 MB | .jpg | |

| Dimensional drawing | MCAD FC A3 IP20 AB | 26 Jan, 2025 | 2.3 MB | .jpg | |

| Dimensional drawing | MCAD FC A3 IP20 ABC | 25 Jan, 2025 | 2.1 MB | ||

| Dimensional drawing | MCAD FC A3 IP20 ABC | 27 Jan, 2025 | 9.2 MB | .stp | |

| Dimensional drawing | MCAD FC A3 IP20 ABC | 27 Jan, 2025 | 3.4 MB | .jpg | |

| Dimensional drawing | MCAD FC A3 IP21 | 26 Jan, 2025 | 1.6 MB | ||

| Dimensional drawing | MCAD FC A3 IP21 | 26 Jan, 2025 | 3.0 MB | .jpg | |

| Dimensional drawing | MCAD FC A3 IP21 B | 25 Jan, 2025 | 1.7 MB | ||

| Dimensional drawing | MCAD FC A3 IP21 B | 26 Jan, 2025 | 3.0 MB | .jpg | |

| Dimensional drawing | MCAD FC A3 IP21 B | 25 Jan, 2025 | 13.8 MB | .stp | |

| Dimensional drawing | MCAD FC A3 IP21 B | 30 Jan, 2025 | 3.2 MB | .dxf | |

| Dimensional drawing | MCAD FC A5 IP55 66 | 25 Jan, 2025 | 27.6 MB | .stp | |

| Dimensional drawing | MCAD FC A5 IP55 66 | 25 Jan, 2025 | 10.2 MB | .dxf | |

| Dimensional drawing | MCAD FC A5 IP55 66 | 26 Jan, 2025 | 1.0 MB | ||

| Dimensional drawing | MCAD FC A5 IP55 66 w switch | 25 Jan, 2025 | 55.7 MB | .stp | |

| Dimensional drawing | MCAD FC A5 IP55 66 w switch | 26 Jan, 2025 | 1.1 MB | ||

| Dimensional drawing | MCAD FC A5 IP55 66 w switch | 26 Jan, 2025 | 11.4 MB | .dxf | |

| Dimensional drawing | MCAD FC B1 IP21 | 26 Jan, 2025 | 2.2 MB | .jpg | |

| Dimensional drawing | MCAD FC B1 IP21 WITH DISCONNECTOR | 25 Jan, 2025 | 2.3 MB | .jpg | |

| Dimensional drawing | MCAD FC B1 IP21 WITH DISCONNECTOR | 25 Jan, 2025 | 20.0 MB | .stp | |

| Dimensional drawing | MCAD FC B2 IP21 WITH DISCONNECTOR | 25 Jan, 2025 | 2.3 MB | ||

| Dimensional drawing | MCAD FC B4 IP20 | 26 Jan, 2025 | 6.1 MB | .dxf | |

| Dimensional drawing | MCAD FC B4 IP20 | 26 Jan, 2025 | 10.4 MB | .stp | |

| Dimensional drawing | MCAD FC B4 IP20 | 26 Jan, 2025 | 2.4 MB | .jpg | |

| Dimensional drawing | MCAD FC B4 IP20 | 26 Jan, 2025 | 2.0 MB | ||

| Dimensional drawing | MCAD FC B4 IP20 OPTION | 27 Jan, 2025 | 10.8 MB | .stp | |

| Dimensional drawing | MCAD FC B4 IP20 OPTION | 25 Jan, 2025 | 2.4 MB | .jpg | |

| Dimensional drawing | MCAD FC B4 IP20 OPTION | 26 Jan, 2025 | 2.0 MB | ||

| Dimensional drawing | MCAD FC B4 IP20 OPTION | 26 Jan, 2025 | 6.3 MB | .dxf | |

| Dimensional drawing | MCAD FC B4 IP21 | 27 Jan, 2025 | 12.7 MB | .stp | |

| Dimensional drawing | MCAD FC B4 IP21 | 26 Jan, 2025 | 2.1 MB | .jpg | |

| Dimensional drawing | MCAD FC B4 IP21 | 26 Jan, 2025 | 8.4 MB | .dxf | |

| Dimensional drawing | MCAD FC B4 IP21 | 27 Jan, 2025 | 2.0 MB | ||

| Dimensional drawing | MCAD FC C2 IP21 | 26 Jan, 2025 | 6.3 MB | ||

| Dimensional drawing | MCAD FC C2 IP21 | 25 Jan, 2025 | 1.8 MB | .jpg | |

| Dimensional drawing | MCAD FC C2 IP21 | 26 Jan, 2025 | 21.4 MB | .stp | |

| Dimensional drawing | MCAD FC C3 IP20 | 26 Jan, 2025 | 2.6 MB | .jpg | |

| Dimensional drawing | MCAD FC C3 IP20 | 26 Jan, 2025 | 14.0 MB | .dxf | |

| Dimensional drawing | MCAD FC C3 IP20 | 25 Jan, 2025 | 14.5 MB | .stp | |

| Dimensional drawing | MCAD FC C3 IP20 | 27 Jan, 2025 | 2.7 MB | ||

| Dimensional drawing | MCAD FC C3 IP20 OPTION | 26 Jan, 2025 | 2.9 MB | ||

| Dimensional drawing | MCAD FC C3 IP20 OPTION | 26 Jan, 2025 | 13.8 MB | .stp | |

| Dimensional drawing | MCAD FC C3 IP20 OPTION | 27 Jan, 2025 | 2.7 MB | .jpg | |

| Dimensional drawing | MCAD FC C3 IP20 OPTION | 30 Jan, 2025 | 15.4 MB | .dxf | |

| Dimensional drawing | MCAD FC C3 IP21 | 27 Jan, 2025 | 2.3 MB | .jpg | |

| Dimensional drawing | MCAD FC C3 IP21 | 26 Jan, 2025 | 19.8 MB | .stp | |

| Dimensional drawing | MCAD FC C4 IP20 | 25 Jan, 2025 | 3.2 MB | ||

| Dimensional drawing | MCAD FC C4 IP20 | 25 Jan, 2025 | 3.0 MB | .jpg | |

| Dimensional drawing | MCAD FC C4 IP20 | 25 Jan, 2025 | 12.7 MB | .stp | |

| Dimensional drawing | MCAD FC C4 IP20 | 26 Jan, 2025 | 18.2 MB | .dxf | |

| Dimensional drawing | MCAD FC C4 IP20 OPTION | 26 Jan, 2025 | 3.3 MB | ||

| Dimensional drawing | MCAD FC C4 IP20 OPTION | 26 Jan, 2025 | 3.0 MB | .jpg | |

| Dimensional drawing | MCAD FC C4 IP21 | 25 Jan, 2025 | 2.3 MB | ||

| Dimensional drawing | MCAD FC D1h 177r0374 | 26 Jan, 2025 | 1.6 MB | .dxf | |

| Dimensional drawing | MCAD FC D1n | 27 Jan, 2025 | 2.0 MB | ||

| Dimensional drawing | MCAD FC D1n | 27 Jan, 2025 | 6.6 MB | .jpg | |

| Dimensional drawing | MCAD FC D1n | 26 Jan, 2025 | 58.0 MB | .dxf | |

| Dimensional drawing | MCAD FC D1n | 26 Jan, 2025 | 11.4 MB | ||

| Dimensional drawing | MCAD FC D1n | 26 Jan, 2025 | 3.5 MB | .jpg | |

| Dimensional drawing | MCAD FC D1n | 25 Jan, 2025 | 5.0 MB | .jpg | |

| Dimensional drawing | MCAD FC D1n | 26 Jan, 2025 | 3.5 MB | .jpg | |

| Dimensional drawing | MCAD FC D2h 177r0375 | 26 Jan, 2025 | 711.6 KB | ||

| Dimensional drawing | MCAD FC D2n | 26 Jan, 2025 | 28.9 MB | .dxf | |

| Dimensional drawing | MCAD FC D2n | 26 Jan, 2025 | 110.9 MB | .stp | |

| Dimensional drawing | MCAD FC D2n | 27 Jan, 2025 | 4.6 MB | .jpg | |

| Dimensional drawing | MCAD FC D2n | 27 Jan, 2025 | 1.2 MB | ||

| Dimensional drawing | MCAD FC D2n | 27 Jan, 2025 | 3.5 MB | .jpg | |

| Dimensional drawing | MCAD FC D2n | 26 Jan, 2025 | 3.4 MB | .jpg | |

| Dimensional drawing | MCAD FC D2n | 27 Jan, 2025 | 4.0 MB | .jpg | |

| Dimensional drawing | MCAD FC D2n | 26 Jan, 2025 | 12.6 MB | ||

| Dimensional drawing | MCAD FC D3h 177r0339 | 26 Jan, 2025 | 162.1 KB | .dxf | |

| Dimensional drawing | MCAD FC D4h 177r0340 | 26 Jan, 2025 | 3.9 MB | .dxf | |

| Dimensional drawing | MCAD FC D4h 177r0340 | 26 Jan, 2025 | 3.0 MB | .dxf | |

| Dimensional drawing | MCAD FC D4h 177r0340 | 25 Jan, 2025 | 38.1 MB | .stp | |

| Dimensional drawing | MCAD FC D4h 177r0340 | 26 Jan, 2025 | 1.4 MB | ||

| Dimensional drawing | MCAD FC D5h 177r0490 | 26 Jan, 2025 | 2.5 MB | .dxf | |

| Dimensional drawing | MCAD FC D5h 177r0490 | 25 Jan, 2025 | 191.2 KB | .dxf | |

| Dimensional drawing | MCAD FC D5h 177r0490 | 26 Jan, 2025 | 2.5 MB | .dxf | |

| Dimensional drawing | MCAD FC D6h 177r0491 | 26 Jan, 2025 | 42.4 MB | .stp | |

| Dimensional drawing | MCAD FC D6h 177r0491 | 26 Jan, 2025 | 1.1 MB | ||

| Dimensional drawing | MCAD FC D6h 177r0491 | 26 Jan, 2025 | 41.8 MB | .stp | |

| Dimensional drawing | MCAD FC D6h 177r0491 | 27 Jan, 2025 | 42.3 MB | .stp | |

| Dimensional drawing | MCAD FC D7h 177r0492 | 26 Jan, 2025 | 2.8 MB | .dxf | |

| Dimensional drawing | MCAD FC D8h 177r0493 | 25 Jan, 2025 | 2.8 MB | .dxf | |

| Dimensional drawing | MCAD FC D8h 177r0493 | 26 Jan, 2025 | 44.8 MB | .stp | |

| Dimensional drawing | MCAD FC E2h IP54 | 25 Jan, 2025 | 2.3 MB | .dxf | |

| Dimensional drawing | MCAD FC E2h IP54 | 26 Jan, 2025 | 628.2 KB | ||

| Dimensional drawing | MCAD FC E3h IP20 | 26 Jan, 2025 | 1.9 MB | .dxf | |

| Dimensional drawing | MCAD FC E4h IP20 | 25 Jan, 2025 | 1.4 MB | .dxf | |

| Dimensional drawing | MCAD FC E4h IP20 | 27 Jan, 2025 | 741.9 KB | ||

| Dimensional drawing | MCAD FC E4h IP20 | 26 Jan, 2025 | 31.9 MB | .stp | |

| Dimensional drawing | MCAD FC E4h IP20 | 25 Jan, 2025 | 2.3 MB | .dxf | |

| Dimensional drawing | MCAD FC E9 | 26 Jan, 2025 | 6.7 MB | .jpg | |

| Dimensional drawing | MCAD FC E9 | 26 Jan, 2025 | 9.1 MB | .jpg | |

| Dimensional drawing | MCAD FC E9 | 27 Jan, 2025 | 1.1 MB | ||

| Dimensional drawing | MCAD FC E9 | 27 Jan, 2025 | 30.7 MB | .stp | |

| Dimensional drawing | MCAD FC F1 F2 F3 F4 F18 Back in out Kit | 26 Jan, 2025 | 4.4 MB | ||

| Dimensional drawing | MCAD FC F1 F2 F3 F4 F18 Back in out Kit | 30 Jan, 2025 | 22.0 MB | .dxf | |

| Dimensional drawing | MCAD FC F1 F2 F3 F4 IP54 Mounting | 26 Jan, 2025 | 5.1 MB | ||

| Dimensional drawing | MCAD FC F1 F2 F3 F4 IP54 Mounting | 30 Jan, 2025 | 28.2 MB | .dxf | |

| Dimensional drawing | MCAD FC F1 F2 F3 F4 IP54 Side Entry Kit | 25 Jan, 2025 | 343.3 KB | ||

| Dimensional drawing | MCAD FC F1 F2 F3 F4 IP54 Side Entry Kit | 26 Jan, 2025 | 1.5 MB | .dxf | |

| Dimensional drawing | MCAD FC F1 F2 IP54 Input Terminals | 25 Jan, 2025 | 3.0 MB | ||

| Dimensional drawing | MCAD FC F1 F2 IP54 Input Terminals | 30 Jan, 2025 | 16.1 MB | .dxf | |

| Dimensional drawing | MCAD FC F1 F3 F10 F11 F18 Output Term | 26 Jan, 2025 | 19.1 MB | .dxf | |

| Dimensional drawing | MCAD FC F1 F3 F10 F11 F18 Output Term | 26 Jan, 2025 | 3.9 MB | ||

| Dimensional drawing | MCAD FC F1 IP54 | 25 Jan, 2025 | 43.4 MB | .stp | |

| Dimensional drawing | MCAD FC F10 F11 Back in out Cooling Kit | 25 Jan, 2025 | 2.2 MB | ||

| Dimensional drawing | MCAD FC F10 F11 Back in out Cooling Kit | 30 Jan, 2025 | 12.0 MB | .dxf | |

| Dimensional drawing | MCAD FC F12 F13 Back in out Cooling Kit | 27 Jan, 2025 | 2.3 MB | ||

| Dimensional drawing | MCAD FC F12 F13 Back in out Cooling Kit | 30 Jan, 2025 | 12.7 MB | .dxf | |

| Dimensional drawing | MCAD FC F18 | 26 Jan, 2025 | 5.2 MB | ||

| Dimensional drawing | MCAD FC F18 | 26 Jan, 2025 | 4.6 MB | .jpg | |

| Dimensional drawing | MCAD FC F18 IP54 Mounting | 26 Jan, 2025 | 28.4 MB | .dxf | |

| Dimensional drawing | MCAD FC F18 IP54 Mounting | 26 Jan, 2025 | 28.3 MB | .dxf | |

| Dimensional drawing | MCAD FC F18 IP54 Mounting | 25 Jan, 2025 | 28.5 MB | .dxf | |

| Dimensional drawing | MCAD FC F18 IP54 Mounting | 26 Jan, 2025 | 28.4 MB | .dxf | |

| Dimensional drawing | MCAD FC F18 IP54 Mounting | 26 Jan, 2025 | 4.0 MB | ||

| Dimensional drawing | MCAD FC F18 IP54 Mounting | 30 Jan, 2025 | 28.6 MB | .dxf | |

| Dimensional drawing | MCAD FC F2 F4 F12 F13 Output Terminals | 26 Jan, 2025 | 18.6 MB | .dxf | |

| Dimensional drawing | MCAD FC F2 F4 F12 F13 Output Terminals | 26 Jan, 2025 | 3.6 MB | ||

| Dimensional drawing | MCAD FC F2 IP54 | 25 Jan, 2025 | 47.8 MB | .stp | |

| Dimensional drawing | MCAD FC F3 F4 F18 Input Terminals | 26 Jan, 2025 | 1.8 MB | ||

| Dimensional drawing | MCAD FC F3 F4 F18 Input Terminals | 30 Jan, 2025 | 11.8 MB | .dxf | |

| Dimensional drawing | MCAD FC F3 IP54 | 26 Jan, 2025 | 54.3 MB | .stp | |

| Dimensional drawing | MCAD FC F4 IP54 | 25 Jan, 2025 | 33.9 MB | .stp | |

| Dimensional drawing | MCAD FC F8 F9 Back in out Cooling Kit | 25 Jan, 2025 | 1.3 MB | ||

| Dimensional drawing | MCAD FC F8 F9 Back in out Cooling Kit | 30 Jan, 2025 | 7.2 MB | .dxf | |

| Dimensional drawing | MCAD FC F8 F9 F10 F11 F12 F13 Input Term | 26 Jan, 2025 | 1.5 MB | ||

| Dimensional drawing | MCAD FC F8 F9 F10 F11 F12 F13 Input Term | 30 Jan, 2025 | 13.9 MB | .dxf | |

| Dimensional drawing | MCAD FC F8 F9 F10 F11 F12 F13 Mounting | 25 Jan, 2025 | 27.7 MB | .dxf | |

| Dimensional drawing | MCAD FC F8 F9 F10 F11 F12 F13 Mounting | 26 Jan, 2025 | 1.3 MB | ||

| Dimensional drawing | MCAD PLV D10H IP54 CIRCUITBREAKER DUDTCM | 25 Jan, 2025 | 2.4 MB | ||

| Dimensional drawing | MCAD PLV D10H IP54 DISCON | 26 Jan, 2025 | 2.5 MB | ||

| Dimensional drawing | MCAD PLV D10H IP54 DISCON DUDT | 26 Jan, 2025 | 2.4 MB | ||

| Dimensional drawing | MCAD PLV D10H IP54 FD CN DDTCM BTEN TPEX | 26 Jan, 2025 | 3.6 MB | ||

| Dimensional drawing | MCAD PLV D10H IP54 FUSDIS CON DUDT CM | 25 Jan, 2025 | 3.5 MB | ||

| Dimensional drawing | MCAD PLV D10H IP54 FUSDISCON | 26 Jan, 2025 | 2.7 MB | ||

| Dimensional drawing | MCAD PLV D10H IP54 WO OPTIONS | 25 Jan, 2025 | 2.2 MB | ||

| Dimensional drawing | MCAD PLV D9H IP54 CON DVDT CM | 26 Jan, 2025 | 2.4 MB | ||

| Dimensional drawing | MCAD PLV D9H IP54 FUSDISCONNECTOR | 26 Jan, 2025 | 2.1 MB | ||

| Dimensional drawing | MCAD PLV D9H IP54 LHDP FUSDIS CON DUDTCM | 26 Jan, 2025 | 3.8 MB | ||

| Dimensional drawing | MCAD PLV D9H IP54 SWITCHDIS DUDT CM | 25 Jan, 2025 | 2.1 MB | ||

| Dimensional drawing | MCAD PLV E5H IP54 CIRCUITBREAKER | 26 Jan, 2025 | 2.8 MB | ||

| Dimensional drawing | MCAD PLV E5H IP54 CONTACTOR | 25 Jan, 2025 | 2.8 MB | ||

| Dimensional drawing | MCAD PLV E5H IP54 DISCON CON DVDT | 26 Jan, 2025 | 3.3 MB | ||

| Dimensional drawing | MCAD PLV E5H IP54 FUSDIS CON TOPEXIT | 26 Jan, 2025 | 3.3 MB | ||

| Dimensional drawing | MCAD PLV E5H IP54 FUSDISCON CONTACTOR | 27 Jan, 2025 | 2.8 MB | ||

| Dimensional drawing | MCAD PLV E5H IP54 LHDP CM DVDT | 25 Jan, 2025 | 3.1 MB | ||

| Dimensional drawing | MCAD PLV E5H IP54 SWITCHDISCON CONTACTER | 27 Jan, 2025 | 2.8 MB | ||

| Dimensional drawing | MCAD PLV E6H IP54 CONTACTOR | 25 Jan, 2025 | 2.8 MB | ||

| Dimensional drawing | MCAD PLV E6H IP54 FU SWI DIS | 25 Jan, 2025 | 2.9 MB | ||

| Dimensional drawing | MCAD PLV E6H IP54 FUS SWI DIS CON | 25 Jan, 2025 | 2.9 MB | ||

| Dimensional drawing | MCAD PLV E6H IP54 SWIDIS CON | 27 Jan, 2025 | 2.9 MB | ||

| Dimensional drawing | MCAD PLV E6H IP54 WO IP | 26 Jan, 2025 | 2.8 MB | ||

| Dimensional drawing | MCAD-FC-B1-IP21-PTM | 25 Jan, 2025 | 45.4 MB | .stp | |

| Dimensional drawing | MCAD-FC-B2-IP21-PTM | 25 Jan, 2025 | 88.7 MB | .stp | |

| Dimensional drawing | MCAD-FC-C1-IP21-PTM | 27 Jan, 2025 | 59.3 MB | .stp | |

| Dimensional drawing | MCAD-FC-C2-IP21-PTM | 27 Jan, 2025 | 90.2 MB | .stp | |

| Circuit diagram | Wiring Schematic FC 102-202 1.1-90 kW | 26 Jan, 2025 | 64.3 KB | ||

| Circuit diagram | Wiring Schematic FC 110-400 kW D-frame | 26 Jan, 2025 | 60.0 KB | ||

| Circuit diagram | Wiring Schematic FC 315-1400 kW | 26 Jan, 2025 | 297.6 KB | ||

| Circuit diagram | Wiring Schematic FC 355-800 kW E | 27 Jan, 2025 | 60.8 KB | ||

| Circuit diagram | Wiring Schematic Low Harmonic Drive | 25 Jan, 2025 | 184.0 KB |