Shell & Core buildings – larger buildings split in smaller zones for rental purpose – such as office buildings or shopping malls are rapidly gaining in popularity. The design and commissioning of the HVAC system in such buildings requires another approach. If this is not taken into account issues like a long handover time, an over-dimensioned and unreliable system will occur.

Shell and core buildings, and their HVAC systems, are typically constructed in two stages. The first stage is construction of the “Shell”. This is achieved according the building owners design. The second stage is the construction of the “Core”, with the completion of the individual zones (mostly shops or offices) according the tenants requirements.

The building owners often have challenges with designing the Shell HVAC system as they don’t know what will be in each individual shop or office. This often results in delays in the handover of the spaces to their renters due to a very complicated commissioning and re-commissioning process. Besides this, the system frequently ends up being over-dimensioned where some zones will get too little flow, while others starve the system.

With the large number of tenants, renting a part of the buildings’ space and making their own designs, the complexity of the HVAC system grows uncontrollable, causing many complaints about poor comfort and a bad working environment. The split responsibilities for the single Shell and many connected Core HVAC systems requires detailed alignment. In practice this is seldom the case though.

Troubleshooting

Currently the only solution to solve all the tenant’s complaints is to involve, mostly expensive, service technicians to do troubleshooting. They might adjust the manual balancing valve settings, install a larger pump or adjust the water temperature. Yet, this will only lead to higher energy costs and not adequately solve the problems as the conditions in the HVAC system are changing constantly.

Hydronic balancing

The main cause of an unreliable or inefficient HVAC system is the lack of proper hydronic balance. In some buildings no zone balancing valves are installed while in others only manual balancing valves are dividing the zones.

As illustrated in figure 1, an unbalanced HVAC system can be compared to the distribution of water from a – perforated - water hose. The zone closest to the tap will get the most flow while there is less and less flow further away. Figure 2 illustrates the functionality of manual balancing valves or flow limiters which ensure uniform distribution at full load conditions. At figure 3. however, is shown that during partial load conditions the distribution of water is no longer correctly balanced, and the over-flow is even worse. As shown in figure 4. the only proper solution is to install differential pressure controllers, which ensure a reliable HVAC system, both at full and partial load conditions.

Hydronic balancing in Shell and Core buildings

Because the HVAC design of each rented space Core is made by the tenant, and the building owner is not involved in the final design, there can be several principle designs. Most common are:

- Several fan coils/terminal units

- One fan coil/terminal unit

- Several fan coils/terminal units with individual room controllers

The building owner needs to install a differential pressure controller in the return pipe from each zone to ensure the best performance and minimize the complaints of the HVAC system. Selecting the correct differential pressure controller is a challenge, as the designer does not know how the design of each individual zone will be.

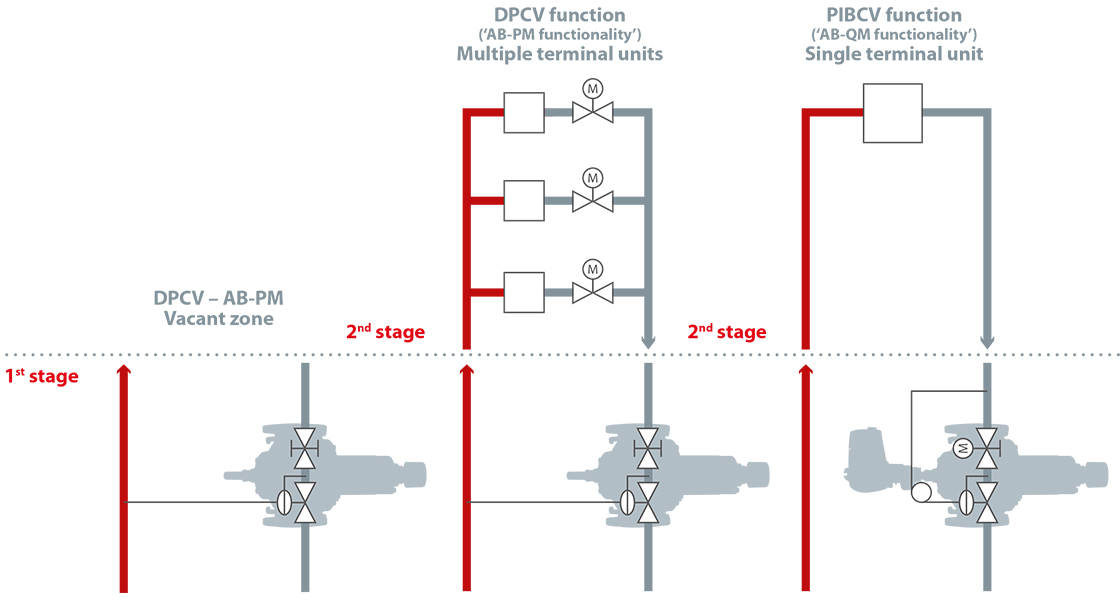

For zones with several fan coils/terminal units, the flow and pressure need to be controlled with a Differential Pressure Control Valve (DPCV), connected to the flow pipe with an impulse tube. When there is only one fan coil the differential pressure and flow can be controlled with a Pressure Independent Balancing and Control Valve (PIBCV), with the impulse tube connected to the return pipe.

- Several fan coils/terminal units

- Differential Pressure Control Valve (DPCV)

- One fan coil/terminal unit

- Pressure Independent Balancing and Control Valve (PIBCV)

- Several fan coils/terminal units with individual room control

- Differential Pressure Control Valve (DPCV)

Not knowing the final and complete HVAC system design might lead to increased costs for building owners of Shell & Core buildings. When the initial installed balancing and control valves don’t fit the tenant’s Core HVAC designs, costly adaptions to the Shell HVAC system need to be made.

How to solve this?

A dedicated solution for Shell & Core buildings

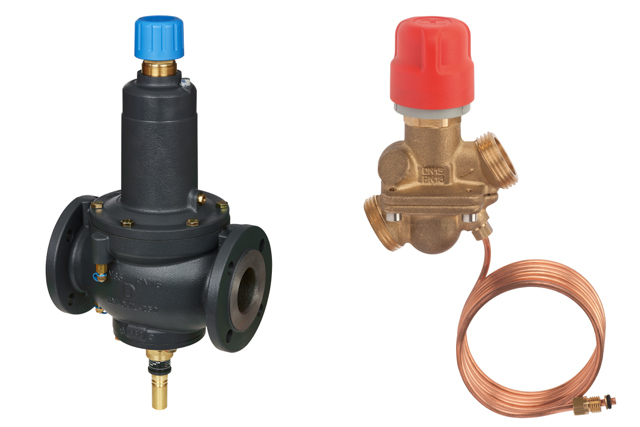

Danfoss offers a new and innovative solution to the challenges in a Shell & Core HVAC system. With the dedicated AB-PM differential pressure control and flow limitation valve, building owners can design and install the Shell of the heating and cooling system in their building before tenants move in. With AB-PM initially installed as DPCV, the building owner is ensured a hydronic balanced HVAC system that can easily be divided into individual zones for each shop or office, without the risk the valves need to be replaced.

Due to its unique design, the valve can easily be changed from DPCV to PIBCV functionality, just by moving the connection of the impulse tube. This makes the AB-PM an ideal solution for Shell & Core Buildings, no matter if the tenants have one or more fan coil/terminal units to heat or cool their office or shop. This feature also allows flexible design and redesign of each zone in case another (new) tenant has other HVAC requirements.

Another advantage of the AB-PM valve is the integrated flow limitation function. This allows automatic limitation of the maximum flow into a zone. This gives the building owner control over the maximum energy consumption/flow in the building.

In case the AB-PM is used for PIBCV or DPCV functionality with one fan coil/terminal unit, it can be equipped with a matching AME435 gear actuator to establish accurate room temperature control.

Conclusion

Danfoss AB-PM provides a dedicated solution for the HVAC design challenges in Shell & Core buildings. By using AB-PM to maintain a specified design flow and differential pressure for each zone of the building, the handover time of the Shell HVAC system can be fastened as less time is needed for installation and commissioning. The unique design of the valve offers 4 functions in one valve for flexible flow control, no matter the HVAC design of the individual shops or offices. AB-PM ensures an optimized, reliable HVAC system with a low Total Cost of Ownership.