So far, the digitalization journey has mainly focused on exploiting technological possibilities in terms of data collection and advanced control monitoring.

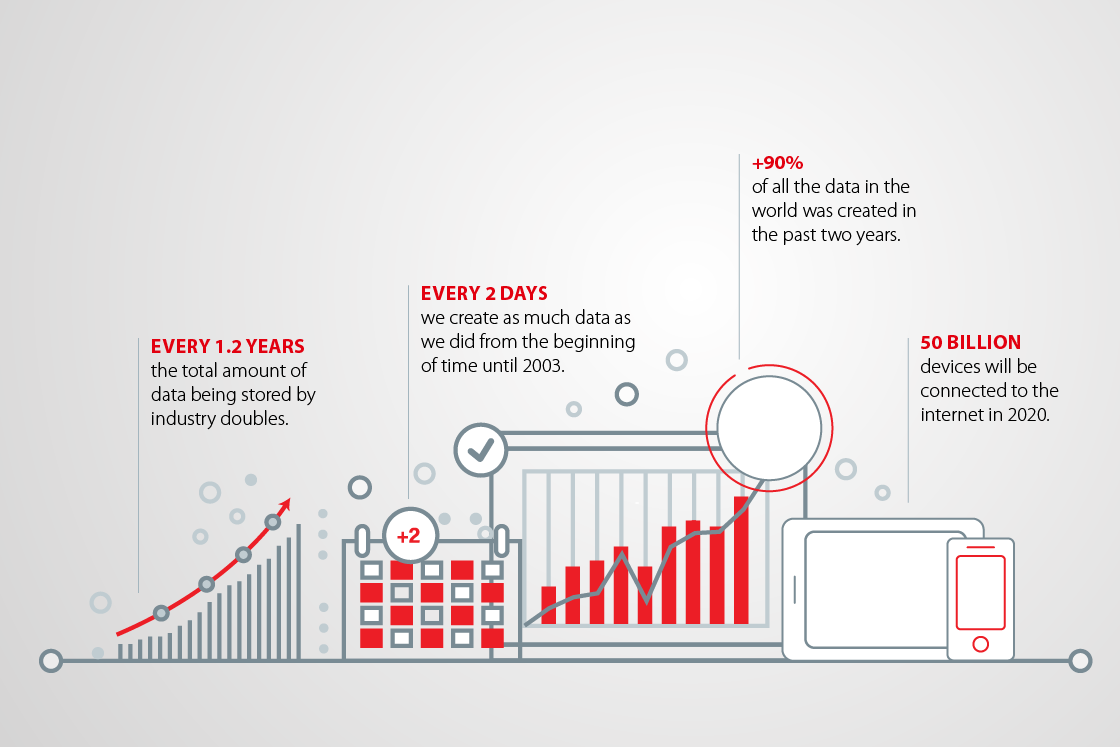

Now, a new era of advanced control systems is expanding to brand-new parts of the industry, as sensors, wireless data communication, smart devices, storage, and computer power have decreased significantly in price.

The big question now is, how will the technological evolution affect the water industry in the near future? And which benefits, possibilities, limitations and obstacles for using data and data processing does the industry face when water installations become more digital?

Industry 4.0 is standardizing digitalization

Industry 4.0 represents the fourth revolution that has occurred in

manufacturing. Even though some dismiss the concept as merely a

marketing buzzword, Industry 4.0 is a German industry-initiated attempt to set standards and general guidelines for digitalization.

The true power of Industry 4.0 is the acknowledgment that individual

initiatives and propriety standards are outdated. Real value occurs when data and information is shared. The more connected and interlinked things are, the more we gain. The more access, the more viability.

This means that in order to harvest full value of digitalization, companies in the water industry have to follow present global standards for connectivity,

data storage, availability and legislation – and provide easy integration with other systems.

Thus, new water technology systems need to be developed – based on new data sources, more intelligent products, and robust planning tools. Also needed are more service-based business models, collaborative systems based on intelligent water technology components, and multiutility systems that combine water treatment, energy, and resource recovery in a cyber-safe framework. Hence, having the right products together with an understanding of customer needs and applications, combined with intelligent connectivity, are key factors for success in the water industry for the years to come.