Enter a new dimension of district energy

Discover ultimate network resilience and energy efficiency with Danfoss Titan™ for continuous optimization of substation performance.

Let's unlock the grid

As the complexity of district energy continues to increase, demands for a stable and efficient grid have never been higher. This makes digitalization the fundamental lever for new generations of district energy and for an optimized grid—from production to distribution and consumption.

Danfoss boasts the industry’s only complete portfolio of proven end-to-end solutions—from innovative technology and components to optimization tools and services. Combined with our extensive hardware domain knowledge and years of experience, we can help today’s utilities not only optimize their supply of district heating but also impact decarbonization and energy consumption in cities.

It’s time to unlock the grid’s full potential. For ultimate cost-effectiveness, energy efficiency, and resilience on the path to a greener future.

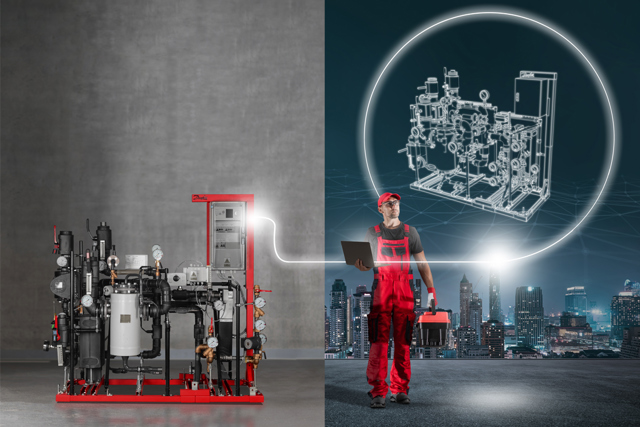

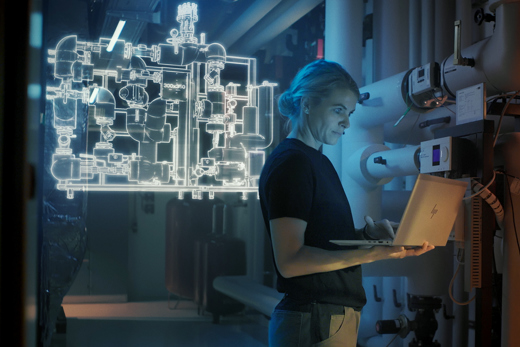

Digital twin technology for substations - Danfoss Titan™

Discover Danfoss Titan™: a groundbreaking solution with digital twin technology. Achieve correct commissioning, enhanced performance, and the lowest return temperature. With intuitive cloud commissioning and continuous optimization, you ensure optimal settings for different working conditions. Enjoy 1-3 °C reduction in return temperature, actionable insights , reliability, and the shortest commissioning time. Experience energy efficiency and savings like never before.

Articles

Unlock in-depth knowledge and inspiration

Turn your waste heat into financial gains and lower emissions

Unlock the value of waste heat and optimize energy use with sector coupling. Discover how combining heating and cooling systems can cut costs, reduce emissions, and support your sustainability goals.

Decarbonization with integrated cooling and heating energy systems and heat recovery

Join Drew Turner as he breaks down the art of merging diverse energy sectors to boost efficiency and drive decarbonization efforts. Learn about the innovative, yet practical ways to harness this strategy, like repurposing excess heat from cooling systems for heating needs elsewhere. You’ll also discover the potential of integrating renewable energy sources into the power grid, while addressing the challenge of supply-demand equilibrium.

Trends driving district energy

The shift in the district energy sector from single source to multi-source, from fossil fuels to renewables and surplus energy, and from high temperature to low temperature district heating, brings with it several key challenges.

Danfoss end-to-end district energy solutions deliver actionable insights enabling continuous optimization and optimal temperature control on both demand and supply side.

Sector coupling: smart energy videocasts

Introducing the smart side of the energy system using sector coupling to connect the different energy sectors. This setup can support decarbonizing the energy supply and fight against climate change.

We also encourage you to watch our case specific videos from Copenhagen and Sonderborg on how small- and large-scale district heating systems play an integral part of sector coupling.

Re-engineering energy efficiency: Heat networks explored

District energy networks can make a huge impact on the road to decarbonization. Find out why – and how the Danfoss HQ walks the talk – in this podcast with Jonas Loholm Hamann, Head of Business Development for Danfoss District Energy.

Let’s unlock the potential of district heating

Can existing supply chains handle increased pressure? Is there a way to develop networks effectively while delivering safety and comfort for the end user? Moreover, how can we maximize the use of renewable resources to deliver reliable and safe heating? If you are wondering what district energy means for your network operation or planned renovation, listen to the recording from our live stream.

End-to-end optimization

Addressing main challenges in district energy

Uncover the potential of district heating

Increasing the share of Europe’s heat demand covered by district heating will boost both savings and energy efficiency. Check out our infographic to explore the potential in district heating systems.

How we can help you

Product portfolio for district heating and cooling applications in networks and buildings

Consultancy and customer dedication

Innovation, technical optimization and performance

Safety and reliability in cooperation

Global reach with strong local representation and know-how

One experienced partner for optimal plant operation, optimal network operation and delivering perfect service to your customers

Tools and apps

Case studies

-

if (isSmallPicture) {

DrivePro® services enhance security of heat supply for 49,000 apartments in Gliwice

DrivePro® services enhance security of heat supply for 49,000 apartments in GliwicePOLAND: At district heating company PEC Gliwice, AC drives reduce energy consumption of electric motors by up to 40%. DrivePro® Site Assessment audits help ensure optimal efficiency.

-

if (isSmallPicture) {

Successful transition from oil boilers to a local heating network in Eurasburg

Successful transition from oil boilers to a local heating network in EurasburgIn the Wittelsbacher Land near Augsburg the local network in Eurasburg supplies heat to 80 buildings using a wood chip heating system. Danfoss’ substations ensure efficient heating in all building types, and its modern SCADA solution enables remote system monitoring and management.

-

if (isSmallPicture) {

Electrification and sector coupling achieve CO2 goals at FlexHeat Nordhavn

Electrification and sector coupling achieve CO2 goals at FlexHeat NordhavnDENMARK: The FlexHeat district heating plant at Copenhagen’s Nordhavn harbor emits 315 fewer tonnes per annum of CO2 than the LPG gas-based alternative.

-

if (isSmallPicture) {

World leader in biogas reduces CO2 emissions by 50,000 t annually

World leader in biogas reduces CO2 emissions by 50,000 t annuallyBy generating power and heat from biogas instead of fossil fuels, MEC-BioGas reduces its CO2 footprint by 50000 tpa. Danfoss VLT® drives ensure optimal uptime in the 24/7 operations.

-

if (isSmallPicture) {

Full-scale biogas plant in Kalundborg ensures the return of all nutrients back to nature

Full-scale biogas plant in Kalundborg ensures the return of all nutrients back to natureAC drives from Danfoss help convert biomass from insulin and enzyme production to energy.

-

if (isSmallPicture) {

Solar heating plant reduces CO2 emissions by 15,700 tonnes annually

Solar heating plant reduces CO2 emissions by 15,700 tonnes annuallyThe world’s largest solar heating plant in Silkeborg, Denmark harnesses energy to heat the homes and workplaces of 40,000 citizens. It supplies 18-20% of the annual heat consumption in the city of Silkeborg, Denmark, which has an ambitious target of CO2 neutrality in heat production by the year 2030.