Refrigeration is important for maintaining a proper, unbroken cold chain. Using dairy as an example, after the cows are milked, their milk is pasteurized and rapidly chilled. Once the milk has been chilled, it must be maintained at that low temperature from the farm to the grocery store, including during bottling and shipping. If the cold chain is broken, bacteria or fungus can grow, making the food unsafe for human consumption. The United States Department of Agriculture requires that business-owned refrigeration systems have an internal temperature of 40°F or below for refrigerated food and 0°F for frozen food1. Businesses operating refrigerators or freezers above these temperatures face fines and other penalties, so maintaining a reliable temperature is imperative. One of the most popular types of business-owned refrigeration systems is the cold room.

Walk-in coolers and freezers are staples of restaurants, hotels, supermarkets, and any other place that needs to store fresh, frozen, or pre-cooled food products. These walk-ins are enclosed, refrigerated storage spaces that have footprints generally smaller than 3000 square feet and can be used for things such as storing perishable food items or packaging food. Walk-ins are often used as medium-term cold storage—with standard refrigerators acting as short-term storage and refrigerated warehouses acting as long-term storage. Just like any refrigeration system, walk-ins use an evaporator inside the unit and a condenser outside the unit to move heat outside, thus cooling the inside.

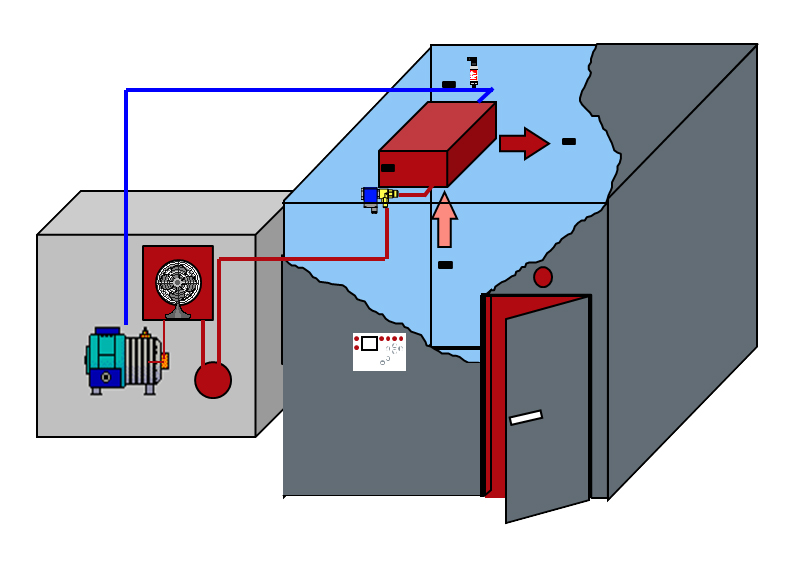

From a broad perspective, there are three kinds of walk-ins: self-contained, remote condensing, and multiplex condensing. Self-contained walk-ins, as the name implies, are cold storage rooms where the refrigeration system is a complete package with the evaporator and condenser in one unit, similar to a window A/C unit. Self-contained walk-ins are typically built outside of buildings which they serve. Remote condensing unit walk-ins have the condenser unit somewhere other than directly adjacent to the room and not packaged with the evaporator, such as on the roof of the building. Remote condensing unit walk-ins are typically built into the buildings they will serve and may have multiple evaporators. Multiplex walk-ins use a centralized system with multiple condensing units and evaporators. Multiplex walk-ins are always built directly into the buildings they serve.

To help walk-ins operate efficiently, their walls are constructed with insulated walls, floors, and ceilings. The insulation material, typically some variety of foam, is sandwiched between thin walls, usually ones made from steel or aluminum. Insulating the walk-in keeps the temperatures inside and out separated, requiring less work from the evaporators and condensers to maintain the temperature and conserving electricity. In addition to being insulated, walk-in floors should also be reinforced to support any equipment and product they will hold.

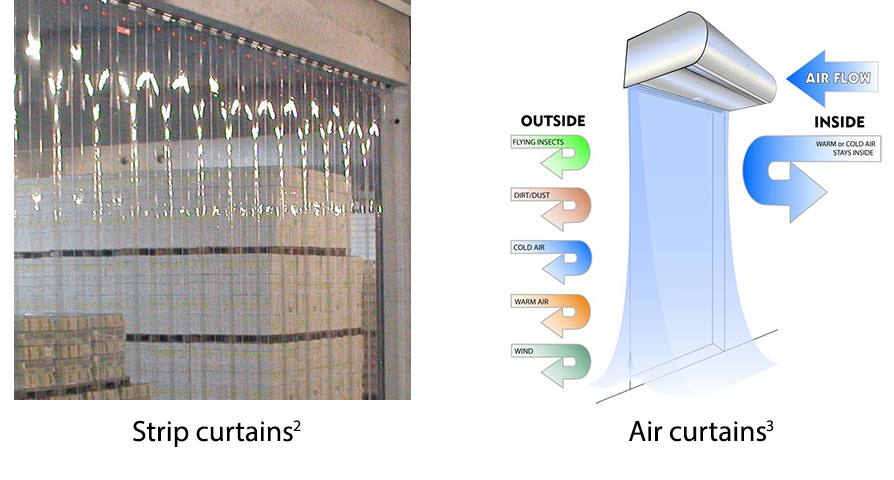

Another way to increase efficiency is to install curtains at the doors. Whenever an employee enters or exits the cooler or freezer, heat from the outside comes into the cold room. This in turn requires the system to use more energy to bring the temperature back down. Curtains help reduce temperature fluctuations inside the walk-in. There are typically two kinds of curtains: strip and air. Strip curtains are made up of thick plastic sheets cut into strips while an air curtain is made up of a wall of air, blasted at a high velocity from directly above the door. Both designs help keep the temperature of walk-in coolers and freezers low and efficiency high.

However they are built, walk-in coolers and freezers are important parts of many different businesses across a multitude of industries.

Join us next time for our detailed look at which components are the best to choose for your walk-in.

Part 2 - Walk-in coolers: compressors and heat exchangers

Part 3 - Walk-in coolers: filter driers and sight glasses

Part 4 - Walk-in coolers: pressure switches, ball valves, and fan speed controllers

Part 5 - Walk-in coolers: thermostatic expansion valves and solenoid valves

Part 6 - Walk-in coolers: temperature controls

Part 7 - Walk-in coolers: a summary

1) https://www.fsis.usda.gov/wps/portal/fsis/topics/food-safety-education/get-answers/food-safety-fact-sheets/safe-food-handling/keep-food-safe-food-safety-basics/

2)http://www.shaverinc.com/soft-wall-solutions/pvc-strip-doors-curtains/

3)http://www.mckeedoor.com/air-curtains/