With the approaching HFC phasedown, the demand for environmentally friendly cooling systems is driving chiller manufacturers to innovate. Washington-based Pro Refrigeration, Inc., a leading manufacturer and supplier of chillers for the industrial and beverage processing market, including the dairy, beer and wine industries, recognized an opportunity with CO₂ chillers. Since, as a natural substance, CO₂ has nearly zero impact on global warming, the company knew that demand would increase in the coming years as their customers look to reduce their environmental impact and comply with local, state and federal regulations.

Most of Pro Refrigeration’s traditional chillers use R404A, which has a GWP rating of 3922. In comparison, CO₂, the baseline for GWP, has a rating of 1. CO₂ also allows refrigeration systems to recover 100% - three times that of chillers using synthetic refrigerants - of the heat rejected from their systems, generating hot water at up to 200 degrees. For Pro Refrigeration, heat recovery capability is an essential product feature. Dairy farms in particular use a high amount of natural gas or propane to heat water for sanitizing and wash-down. Heat recovery technology lowers both their costs and climate impact.

Building the Product

When the company made the decision to move forward with manufacturing, they investigated controls and valves from several major manufacturers. Danfoss control valves had the combination of higher capacities and safety ratings that were required to meet the needs of the project. Danfoss had been supplying components for the company’s industrial chillers for nearly 30 years, so Pro Refrigeration was confident in Danfoss’ ability to meet their production needs. While the global supply chain disruption extended the production timetable, the companies worked together to produce and procure the necessary components.

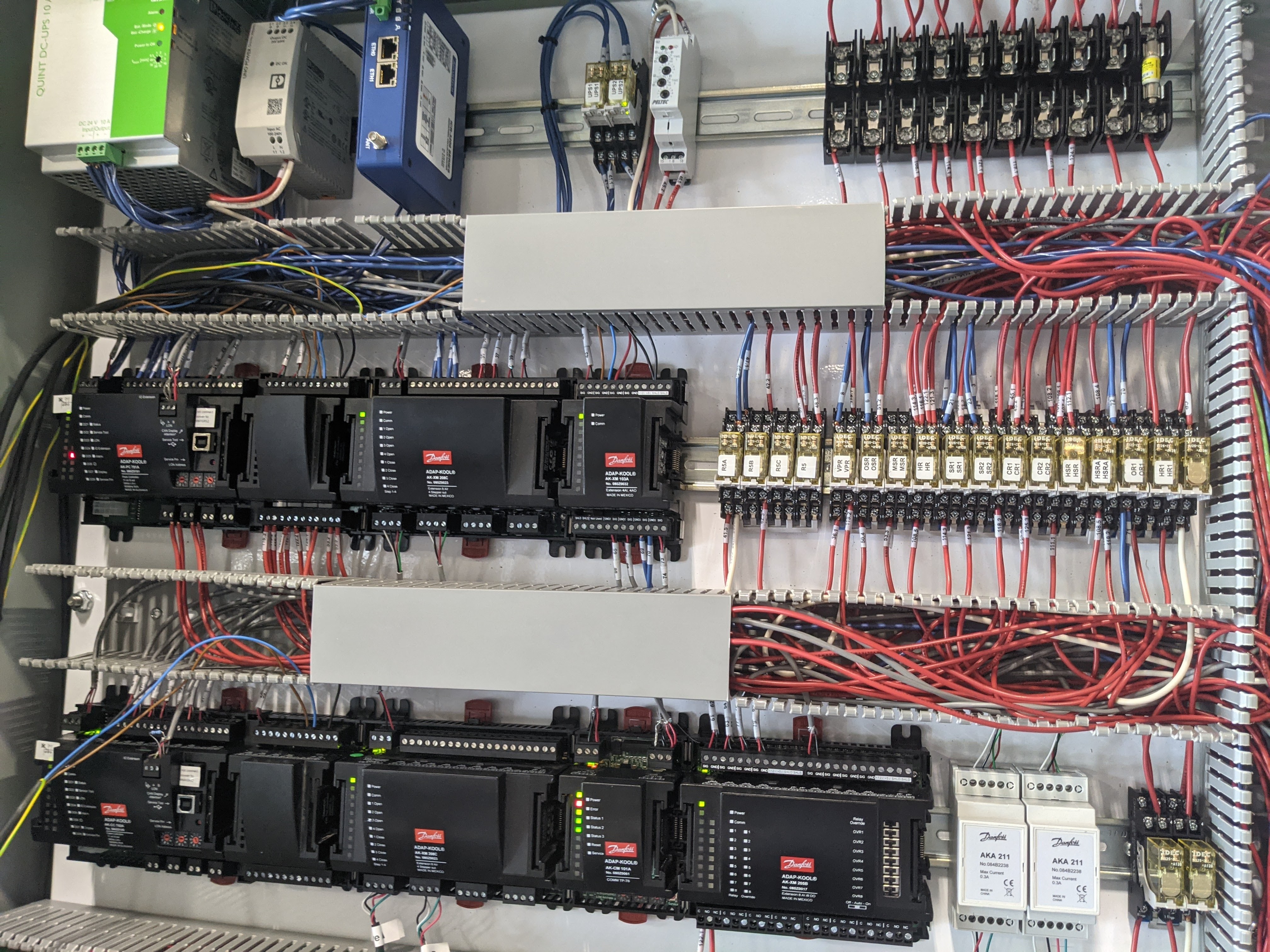

The Danfoss components utilized in the CO₂ chiller include the AK-SM850A system manager, AK-CC 750A case controller, AK-PC781A pack controller, as well as the CCM 20 and CCMT 30 electric regulating valves, BC 5100 pressure switches, pressure and temperature sensors, and other accessories such as AK-PS 250 power supply and GDC gas detector. All of the parts work together to monitor the cooling system, gather data from the sensors, control when the compressors cycle on and off and ensure the fans and expansion valves are working correctly.

“The Danfoss components provide the brains of the system,” explained Jim VanderGiessen, Pro Refrigeration’s co-founder and CEO. “They keep the system running in an optimal manner.” As part of its constant monitoring and adjustment to external conditions, the system manager generates alerts and alarms, so that the facilities staff can immediately identify and address potential mechanical problems. The refrigeration control system also allows Pro Refrigeration engineers to access the data remotely for improved customer support and troubleshooting capabilities.

Putting Innovation into Practice

While using CO₂ as a refrigerant pays dividends for the environment, VanderGiessen noted that it does come at a premium. The chiller costs nearly 30% more to produce than a traditional chiller. While VanderGiessen projected that the cost will come down as the technology becomes mainstream and is deployed across more industries, the current cost presents a barrier to adoption. Fortunately, one of the company’s customers, a California dairy farm, was excited about blazing a new trail and was confident the new chiller would meet its needs.

Installation of the CO₂ chiller was a smooth process, VanderGiessen reported. Pro Refrigeration installers placed the chiller alongside the current system, on the opposite side of the barn, and when the new chiller was ready to begin operating, the crew was able to easily connect the chiller to the rest of the refrigeration system. Pro Refrigeration crews remained on-site to monitor the new chiller around the clock for the first week, until everyone was confident the new chiller was performing as expected.

The chiller, operating at 100 HP, is now fully operational, chilling milk after it passes through a heat exchanger and arrives at a tank for cooling and storage. The chiller has the capacity to service dairy farms of any size, enabling farms to utilize heat recovery on top of the benefits of energy efficiency and low-GWP refrigerants. VanderGiessen noted that the farm has reported the CO₂ chiller “consistently produces colder and higher-quality milk” than its previous 120 HP R404A chiller.

In order for dairy farmers to earn a quality bonus of up to 10% above market rate from milk processors, the milk must be cooled to a temperature below 40 degrees Fahrenheit and run a high temperature CIP (Clean in Place) system every 24 hours to ensure proper system sanitation. Since the CO₂ chiller was installed, the milk temperature has averaged 37.1 F, whereas their previous chiller was unable to cool below 40 F. As a result, the dairy farm was able to see revenue increases in the range of $1,400 to $2,800 per day.

The chiller also recovers the waste heat from the chiller system to heat the wash water, heating 3000 gallons of well water per day from 70 F to 170 F and eliminating the need to use fossil fuels (propane) as a heating source. Early results tracking indicates that the heat recovery operation is saving the farm 40 gallons of propane each day, totaling about $2,100 in savings per month and preventing 517 pounds of carbon emissions from entering the atmosphere.

The Future of CO₂

VanderGiessen is optimistic about the future adoption of CO₂ as a refrigerant, noting that the technology is applicable to any industry with a constant cooling load. Pro Refrigeration has received more inquiries about its latest technology and plans to increase production on CO₂ chillers in the years ahead.

Referencing the pending changes in the industry, VanderGiessen noted that the CO₂ chiller is “a future-proof solution. Our design will evolve and improve over time but we won’t need to build new equipment.” He also noted that while “the price differential needs to ease,” he is confident that “the technology will be considered in all industries. We see a huge opportunity to offer CO₂ chillers across many vertical markets.”

View related products

-

if (isSmallPicture) {

System managers

System managersThe system manager is the key component of the intelligent Danfoss ADAP-KOOL® refrigeration system for food retail.