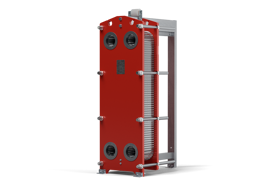

Our traditional, semi-welded, and brazed plate heat exchangers are outstanding choices for standard evaporation duties.

However, certain applications prove unsuitable for regular heat exchanger types. In the interest of guaranteeing unsurpassed product quality, we have created exclusive evaporator plates tailored to meet the challenges presented by advanced evaporation applications.

What does that mean for you?

We are dedicated to making sure that your product quality is first-rate. Our distinctive evaporator plates are made for applications that involve temperature-sensitive or delicate media and excel at multi-stage evaporation of highly concentrated products.

SONDEX® rising film plate evaporators gently treat the media, even if they are highly viscous, and provide uniform evaporation, leading to improved concentrate quality.

Experience first-hand the benefit of our remarkable inlets that eliminate stagnant zones, and evenly distribute the media across the entire heat transmission area for flawless evaporation.

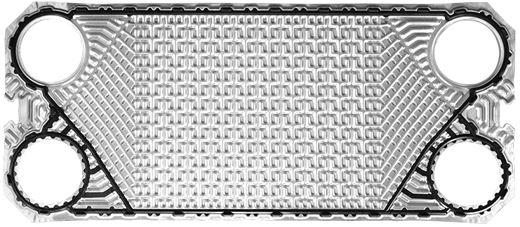

Our special evaporator plates use a Free Flow pattern to create the ideal turbulent flow and reduce the risk of fouling considerably. By doing so, we extend the intervals between cleaning and maximize the uptime of your installation.

Perfect evaporation conditions

The low hold-up volume of SONDEX® evaporators shortens the residence time and provides the best evaporation conditions for temperature-sensitive products.

Operating with low hold-up volumes enables fast start-up and shut down, with only minimal waste, which adds to the overall flexibility of your system and process.

Micro plate technology

Our heat exchangers with the new state-of-the art Micro Plate™ technology feature next-generation efficiency and performance – giving you more from your district heating and cooling applications.

SONDEX® Free flow patterns

The SONDEX® Free Flow pattern is designed to treat media that is unsuitable for regular heat exchangers due to high viscosity, fiber and particle contents, or considerable risk of fouling.

Applications

- Dairy/food/beverage industry

- e.g. food production, like juice and alcohol processing - Sugar industry

- e.g. sugar production, such as concentration of sugar content in sugarcane juice - Biogas industry

- Pulp and paper industry

- Mining industry

- Chemical industry

Technical specifications

- Connections up to DN600

- (Frames designed according to FEA and PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards)

- Plate materials: AISI 304/316, titanium, SMO, Hastelloy. Other materials available upon request

Features and benefits

Special plate design featuring an extra-large inlet connection for steam. Steam consumption can be reduced when operating with multi-stage evaporators, as the product vapor will serve as the heating media.

Flexible design that makes it easy to increase capacity by adding additional cassettes or decrease it to save energy. Low residence time leads to perfect evaporation conditions and superior product quality.

High performance, even with low temperature differences between the media, which is especially great for mechanical vapor recompression (MVR) and thermal vapor recompression (TVR).

Related products

-

if (isSmallPicture) {

SONDEX® Traditional plate heat exchangers

SONDEX® Traditional plate heat exchangersSONDEX® Traditional plate heat exchangers are the ideal choice for a wide range of applications across numerous market segments. We have the largest plate portfolio in the world, and customize each heat exchanger to meet your exact requirements. Innovative technologies and smart design make our traditional plate heat exchangers a stellar investment.