Meet application needs with maximum performance

Our semi-welded plate heat exchangers are optimized for industrial refrigeration applications. The semi-welded plate heat exchangers from Danfoss are designed for ammonia systems and can be used for applications such as condensers, flooded and pumped evaporators, sub-coolers, desuperheaters, superheaters, economizers and oil coolers. The product range includes the sizes SW19-SW59, with more to come, and can handle temperatures ranging from -40°F up to 248°F and pressure ranges up to 300 psi.

Features and benefits

Excellent heat transfer capabilities

Reliable design - operational safety

Easy product configuration

Comprehensive testing

Part of diversified product range for IR systems

New plate design delivers excellent heat transfer capabilities

The SW19-59 range features excellent heat transfer capabilities via improved thermal performance due to optimized plate geometry supporting high turbulent ammonia flow enabling a compact design and supporting lower charge for your refrigeration.

New gasket system improves plate pack stability

The new gasket system ensures high gasket stability and optimal plate alignment due to new gasket and gasket grove design, enabling easy and fast service and maintenance. The new design improves the sealing effect and prevents gasket-blow out. Furthermore, the risk of contamination is reduced due to the double gasket barrier that will drain potential leakages outside of the plate pack. The new gasket system is glue free for easy maintenance.

Easy maintenance and service

The new range is easy to service and maintain. Assembly of the plate heat exchanger is fast and safe thanks to fixed bolt heads and lock bushes that prevent the nut and bolt head from rotating when opening and closing the unit. The enhanced gasket system ensures easy and precise plate pack alignment, which is easy to access due to the non-corrosive nylon roller.

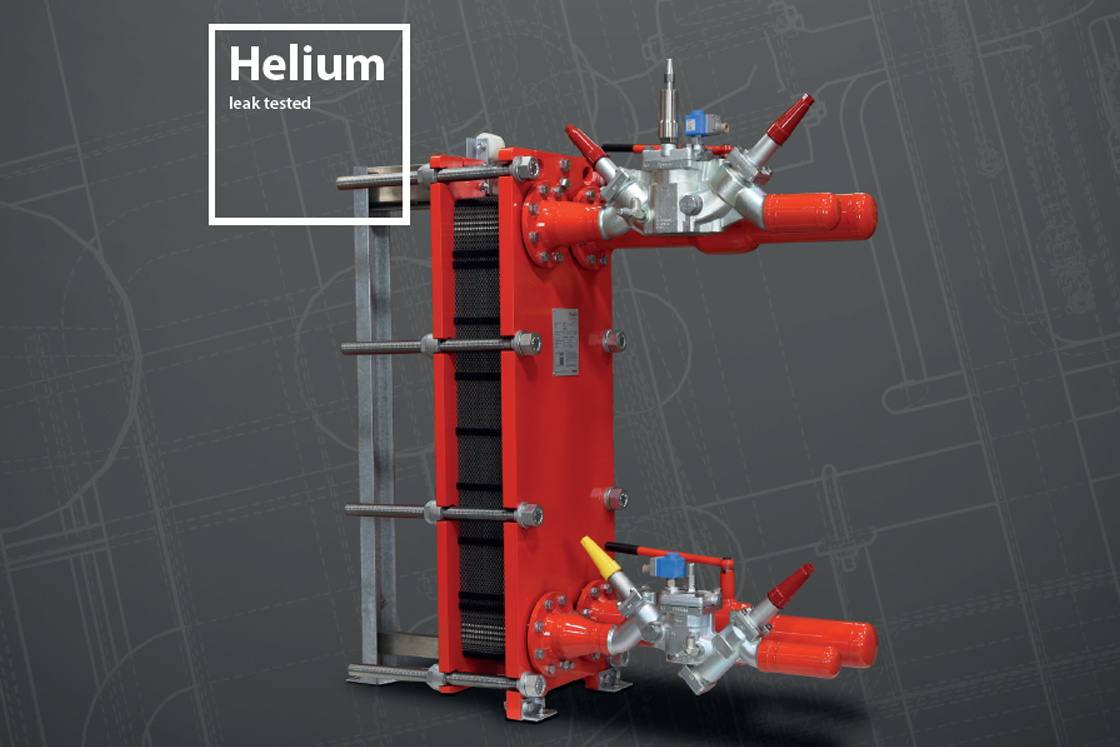

High quality product - fully tested

The Danfoss semi-welded plate heat exchanger design has been verified through thermal and mechanical tests. Furthermore, each semi-welded plate cassette and fully assembled plate heat exchanger are thoroughly leak tested with helium before they leave the Danfoss factory.

Watch video

Explore the new semi-welded plate heat exchanger and see its innovation in design and production.

Download brochure

The new series of semi-welded plate heat exchangers has been optimized for industrial applications and include improvements to both plate design and the gasket system.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Italian | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Russian | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | German | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | English | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Portuguese | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Danish | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | French | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Chinese (CN) | Multiple | 23 Jul, 2019 | 6.7 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Polish | Multiple | 23 Jul, 2019 | 6.2 MB | |

| User guide | Plate Type Heat Exchangers, Single plate and Semi-welded Installation, Commissioning and Maintenance | Spanish, Castilian | Multiple | 23 Jul, 2019 | 6.2 MB | |

| Brochure | Semi-welded plate heat exchanger | Danish | Denmark | 24 Apr, 2019 | 2.8 MB | |

| Brochure | Semi-welded plate heat exchanger | Czech | Czech Republic | 09 Jun, 2021 | 3.5 MB | |

| Brochure | Semi-welded plate heat exchanger | Vietnamese | Vietnam | 22 Nov, 2019 | 9.0 MB | |

| Brochure | Semi-welded plate heat exchanger | Hungarian | Hungary | 17 May, 2021 | 2.8 MB | |

| Brochure | Semi-welded plate heat exchanger | Swedish | Sweden | 14 Mar, 2019 | 2.8 MB | |

| Brochure | Semi-welded plate heat exchanger | English | Multiple | 19 Sep, 2023 | 4.2 MB | |

| Brochure | Semi-welded plate heat exchanger | Finnish | Finland | 14 Mar, 2019 | 2.8 MB | |

| Brochure | Semi-welded plate heat exchanger | Polish | Poland | 06 Aug, 2019 | 2.8 MB | |

| Brochure | Semi-welded plate heat exchanger | Portuguese | Portugal | 06 Aug, 2019 | 2.7 MB | |

| Brochure | Semi-welded plate heat exchanger | Spanish, Castilian | Spain | 05 Mar, 2019 | 8.9 MB | |

| Brochure | Semi-welded plate heat exchanger | Italian | Italy | 04 Mar, 2019 | 8.8 MB | |

| Brochure | Semi-welded plate heat exchanger | French | France | 04 Mar, 2019 | 8.9 MB | |

| Brochure | Semi-welded plate heat exchanger | Turkish | Turkey | 06 Aug, 2019 | 2.8 MB | |

| Brochure | Semi-welded plate heat exchanger | German | Germany | 08 Oct, 2019 | 8.4 MB | |

| Brochure | Полусварные пластинчатые теплообменники | Russian | Multiple | 07 May, 2019 | 2.8 MB |

Related products

-

if (isSmallPicture) {

ICF Flexline™ stainless steel valve station

ICF Flexline™ stainless steel valve stationThe ICF SS valve station offer savings in time, space and money compared to control solutions using conventional components.

-

if (isSmallPicture) {

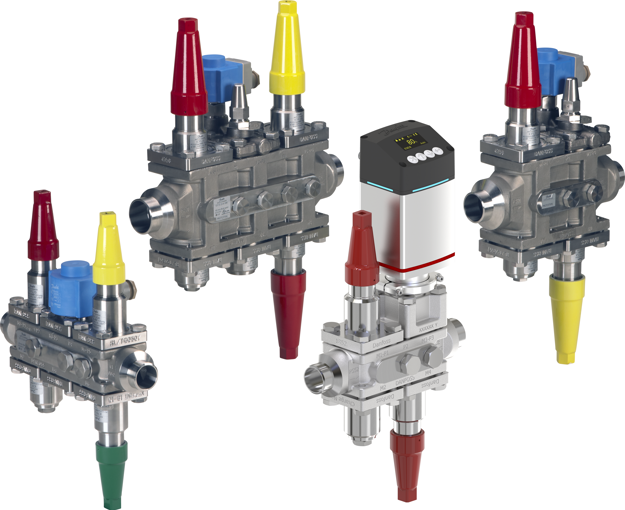

SVL Flexline™

SVL Flexline™SVL Flexline™ product platform targeted to meet industrial refrigeration requirements. The range cover five different functions with just two valve models.

-

if (isSmallPicture) {

Gas detection for industrial refrigeration

Gas detection for industrial refrigerationBased on a digital platform, Danfoss' next generation gas detectors deliver multiple communication and integration options for easy calibration and maintenance, improved reliability, built-in cost effectiveness, and complete regulatory compliance.

-

if (isSmallPicture) {

SVL-140B Parts program

SVL-140B Parts programSVL Flexline™ platform is now expanding to 140 bar MWP to meet an increasing demand of large manual valves in industrial design for large scale R744 transcritical CO2 systems.

-

if (isSmallPicture) {

Pilot valves for ICS Flexline™

Pilot valves for ICS Flexline™Featuring full backwards compatibility, Danfoss' complete line of pilot valves for ICS Flexline™ reduces the number of variants from eight to four, covers all regulation, types, and ranges, and are compatible with HCFCs, non-flammable HFCs, ammonia, and CO2