Better chillers - from the inside out

The constant innovation in chiller design is driven by new demands for energy efficiency, local regulations and standards such as LEED, combined with requirements for new, low GWP refrigerants.

Increasing population, level of comfort and high penetration of IT technologies are putting strong pressure on electric grids and driving up overall energy consumption.

The next generations of chillers and HVAC for new builds as well as retrofits are designed to meet new standards. The revolution in the A/C market opens up new opportunities. To meet the needs of an increasingly complex HVAC market, our extensive range of components offer functional benefits and savings throughout the lifecycle of the chiller system from development and operating costs to servicing and maintenance.

Danfoss can offer different options for meeting these requirements in air-cooled and water-cooled chillers, using scroll, centrifugal or screw technology, with excellent technical support from our expert teams. Compressors can be configured as tandems, trios or using inverter or Turbocor technology. With our electric expansion valves, controllers and sensors we can supply you with the right solutions for a highly efficient air conditioning system that responds quickly to variable operating conditions ensuring constant user comfort.

Start exploring the Top Chiller stories in various buildings.

Scroll chillers

Oil-free chillers

- Denmark new climate friendly hospitality giant depends on Turbocor oil free chiller

- Oil-free compressors maintain consistent performance over time

- 1,400 Ton chillers improve efficiency and lower costs

- Hotel with chiller retrofit

- 12:1 turndown ratio supports dehumidification and energy savings in college

- New TurboChill hydro water-cooled chiller range by Airdale | Video

Optimized data center chillers

Downloads

Features and benefits

All you need in one place, delivered by highly experienced air conditioning experts

High energy efficiency

Products optimized for environmentally friendly, low GWP refrigerants

Reduced applied costs and short payback times

Dedicated technical and customer service around the world

Eco labelling options

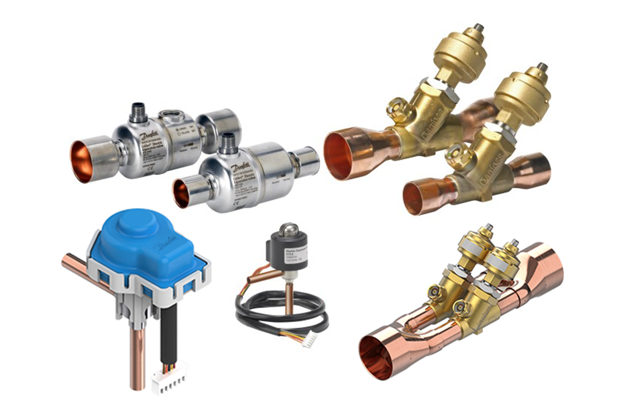

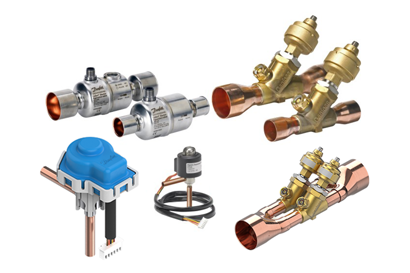

Related products

-

if (isSmallPicture) {

ETS electric expansion valves

ETS electric expansion valvesETS is a series of electric expansion valves for precise liquid injection in evaporators for air conditioning and refrigeration applications. The valve piston and linear positioning design is fully balanced, providing bi-flow feature as well as solenoid tight shut-off function in both flow directions. ETS valves are compatible with electronic control solutions from Danfoss and other manufacturers.

-

if (isSmallPicture) {

Water regulating valves

Water regulating valvesPressure operated water valves are used for regulating the flow of water in refrigeration plants with water-cooled condensers.

-

if (isSmallPicture) {

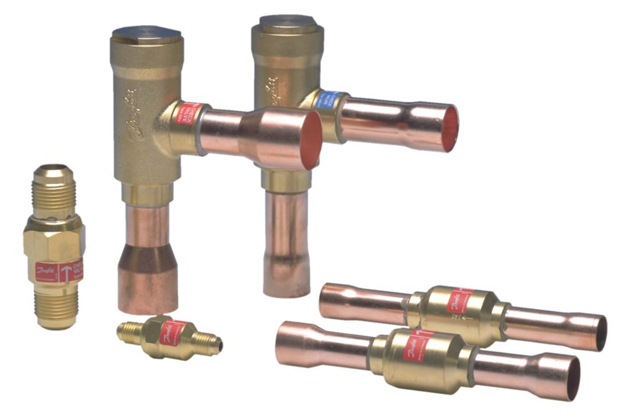

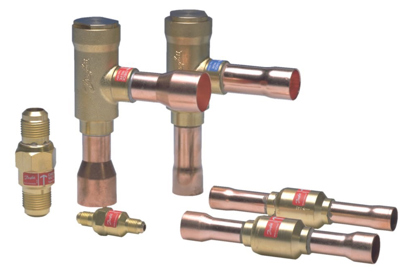

NRV refrigeration check valves

NRV refrigeration check valvesNRV and NRVH can be used in liquid, suction and hot gas lines in refrigeration and air conditioning plants with fluorinated refrigerants. NRV and NRVH can be supplied with flare and solder connections. They are also available with oversize solder connections providing flexibility in the use of check valves.

-

if (isSmallPicture) {

Compressors for refrigeration

Compressors for refrigerationDanfoss focuses on providing energy efficient, sustainable and smart refrigeration compressors for a varied range of commercial applications such as cold rooms, display windows, ice making machines, glass door merchandizers, process cooling etc. Their qualification with lower GWP refrigerants make them compliant with refrigerant regulations such as F-Gas in Europe.

-

if (isSmallPicture) {

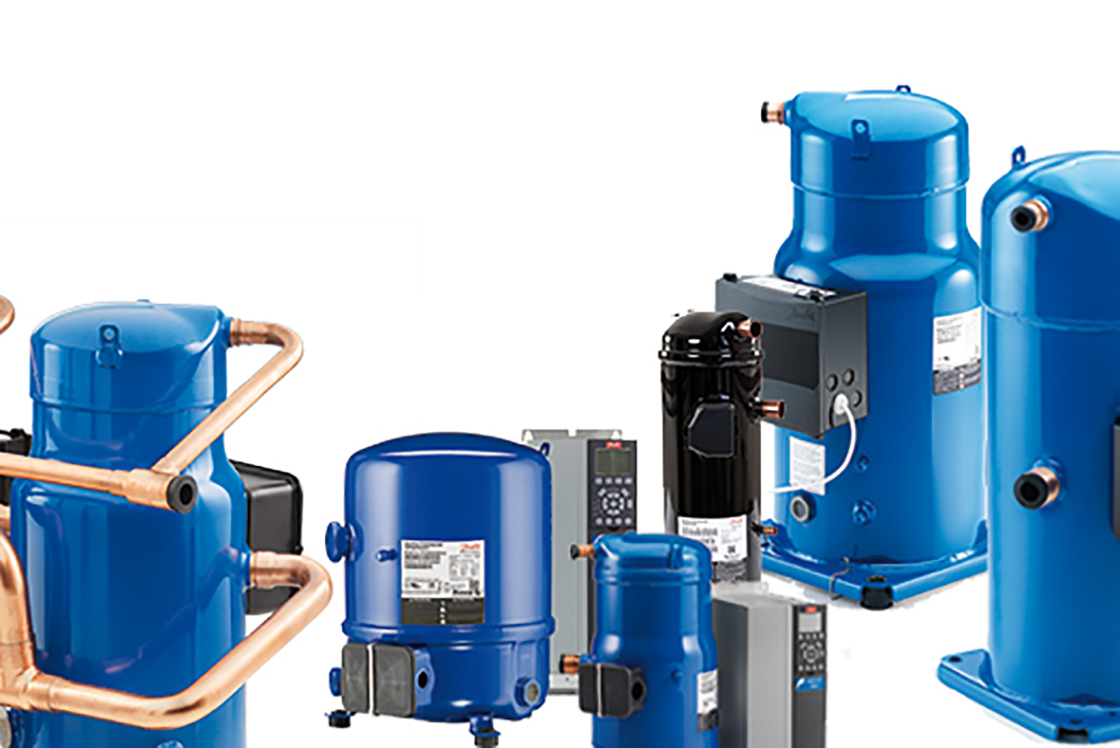

Compressors for air conditioning & heating

Compressors for air conditioning & heatingCompressors for air conditioning, providing enhanced comfort, efficiency and sustainability for rooftops and chillers, commercial applications with refrigerants R410A, R407C, R134a and R22.

Learning

Chillers training program

The HVACR: Chiller training program is designed to give better understanding of Chiller applications and their related solutions. Ready to get started?

Case studies

-

if (isSmallPicture) {

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chiller

Denmark's new climate-friendly hospitality giant depends on Turbocor® oil-free chillerThe new Alsik hotel in Southern Denmark sets a higher standard in energy-efficiency and is built to reach 76% CO₂-neutrality. A main contributor is the 900-kW chillers by Clint (a company of G.I. Industrial Holding) which features award-winning Danfoss Turbocor oil-free compressors.

-

if (isSmallPicture) {

Oil-free compressors maintain consistent performance over time

Oil-free compressors maintain consistent performance over timeDanfoss conducted a study to see how long term operation affected performance on Danfoss Turbocor® compressors. The results showed that oil-free, magnetic bearing compressors maintained consistent performance even after 10+ years of operation.

-

if (isSmallPicture) {

Process chillers

Process chillersVariable speed with Danfoss Turbocor Oil free centrifugal compressor guarantees reliable process cooling and efficient comfort cooling in factory

-

if (isSmallPicture) {

Hotel with chiller retrofit

Hotel with chiller retrofitInverter chiller retrofit brings huge savings in a five star hotel installation, operating and maintenance costs, with compact Danfoss inverter oil–free compressor Turbocor®.

-

if (isSmallPicture) {

Research laboratories

Research laboratoriesRenovation of Key Laboratory in Shanghai illustrates the benefits of temperature control and energy savings in critical applications with inverter technologies

-

if (isSmallPicture) {

Shopping malls

Shopping mallsInverter technology is improving one of the world's largest home DYI stores and helping gain Brazil’s first sustainability certificate with an innovative air conditioning installation.

News

-

if (isSmallPicture) {

New generation conversion tool for discontinued productsThursday, 22 June 2023

New generation conversion tool for discontinued productsThursday, 22 June 2023The DrivePro® Retrofit conversion tool helps you to find the most suitable successor drive.

-

if (isSmallPicture) {

Reduce energy consumption and go green with the Danfoss Heat Recovery UnitMonday, 4 April 2022

Reduce energy consumption and go green with the Danfoss Heat Recovery UnitMonday, 4 April 2022The focus on cutting energy consumption and reducing the carbon footprint has never been greater, but results are often achieved by compromising usability or efficiency. The Danfoss Heat Recovery Unit delivers strong environmental benefits as well as significant reductions on heating bills—all delivered with a short ROI.

-

if (isSmallPicture) {

Mains loss detection just got quickerMonday, 2 August 2021

Mains loss detection just got quickerMonday, 2 August 2021Detect loss of mains power supply within 2 seconds using the new integrated detection function in the VLT® AutomationDrive FC 302. Win competitive edge with less system complexity, lower cost, and faster commissioning – just set and forget.

Contact us

For further information, please contact us.