The famous Austrian brewery, Wieselburger constantly aims to use the newest technology to ensure high product quality and efficiency. Danfoss VLT® FlexConcept® helps them secure flexibility, fewer motor variants and energy efficient operation.

The brewery in Wieselburg can look back on years of tradition. Starting as an independent brewery in 1650 it is now the cornerstone of today’s Austrian beer metropolis, Brau Union Österreich Group, which is owned by Heineken. Skilled brewers and newest technology ensure a sustainable and environmentally friendly production in order to achieve the highest quality.

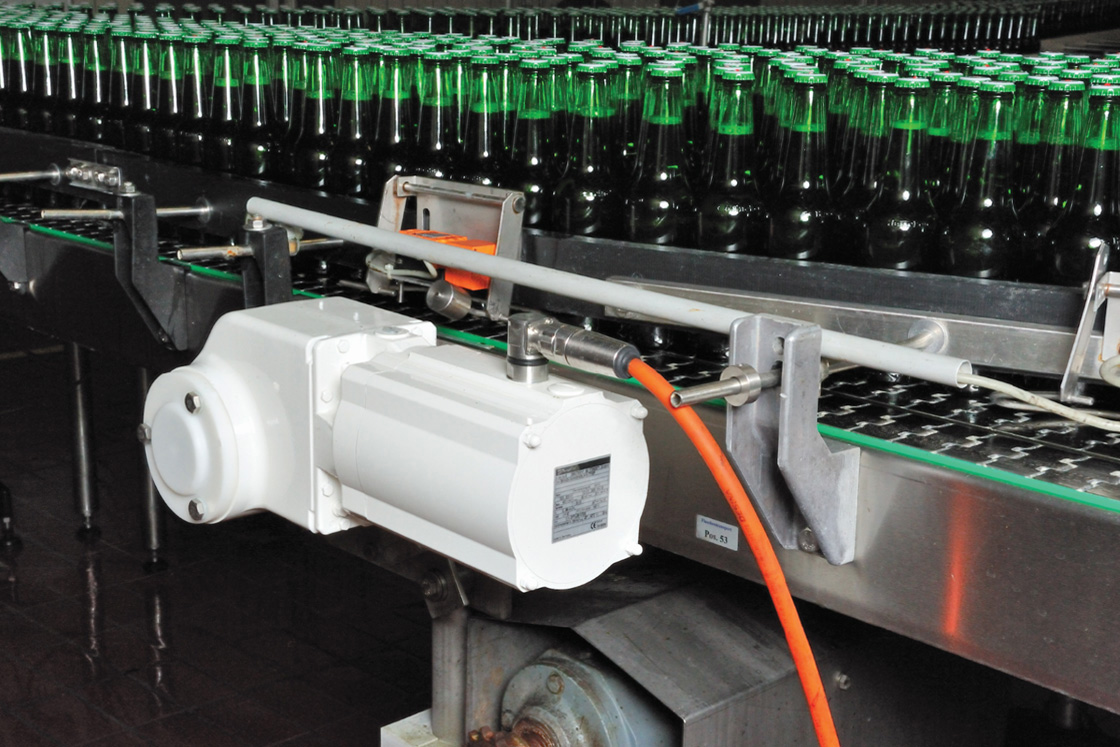

Efficient Upgrade of Filling Line

In June 2010 the brewery embarked on a retrofit project, choosing the VLT® OneGearDrive® from Danfoss’ VLT FlexConcept to replace the aging drives on one of the brewery’s filling lines. The old motors, which used chains as reduction gears, started showing their age and finding spare parts was becoming increasingly difficult. The brewery therefore decided to replace the motors in steps. This enabled them to introduce more energy efficient technology while using the old motors for spare parts for repairs at short notice.

Unchained Advantage

One of the main benefits of installing OneGearDrives is that the factory no longer needs chains to connect the gearbox to the conveyor shaft, as the drive is mounted directly on the conveyor shaft.

“Chains alone introduce system efficiency losses of up to 10%. Also, they are cumbersome to fit and add additional maintenance costs for spare parts and lubrication. The OneGearDrive solves this elegantly and efficiently by simplifying the installation. The hygienic design of the drives also makes it easier to clean, as there are no cooling fins, sharp edges and other areas where dust can accumulate,” explains sales engineer Michael Hitter from Danfoss.

Easy Integration

By sharing the same design and operation principles as the brewery’s many other VLT drives, the new drive solution was relatively easy to integrate into the existing setup. The brewery already had positive experiences with the Danfoss frequency converters that were already installed in a central control concept, where the frequency converters are grouped in switch rooms or panels.

Wieselburg already had several VLT® 5000 and VLT® 2800 drives running in the plant.

The new OneGearDrives are controlled by VLT® AutomationDrive FC 302 units. All of them work very well and the brewery expresses satisfaction with their performance.

In October 2012 Wieselburger installed new equipment, after specifying to their supplier that OneGearDrives were to be used as part of solution, bringing the total count of OneGearDrives in the Wieselburg plant past 30.