The Tavina bottling plant in Salo, Italy has a capacity of over 100,000 bottles per hour, equivalent to a potential of 400 million per year, which are distributed in 25 countries globally.

To achieve higher productivity and energy efficiency on two new bottling lines, Tavina chose the Danfoss VLT® FlexConcept drive system. The system ensures high performance and optimized management of the bottling lines; and adds value thanks to its almost non-existent use of sensors and/or photocells, thus guaranteeing long-lasting services.

The sensorless system developed by consultants Sacmi Filling has the capacity to manage almost all bottling lines without using control sensors and/or photocells, and can be used in a conventional manner for these applications. This was made possible thanks to a synergetic mix between Sacmi Filling know-how and skills, along with the services provided by the Danfoss VLT® FlexConcept drive system.

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC301 / FC302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC301) and an advanced high dynamic version (FC302) with additional functionalities.

-

if (isSmallPicture) {

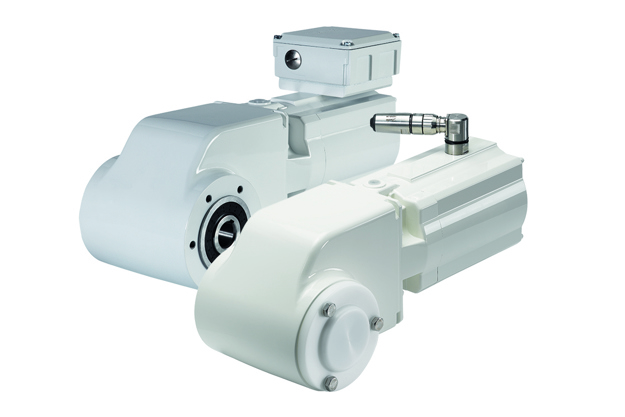

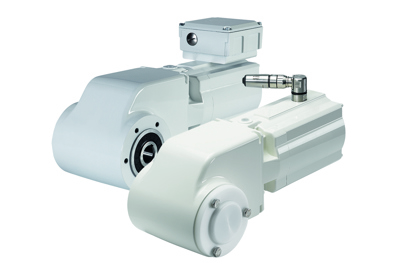

VLT® Decentral Drive FCD 302

VLT® Decentral Drive FCD 302Thanks to its rugged design, the FCD302 drive can be mounted close to motors in demanding applications.

-

if (isSmallPicture) {

VLT® OneGearDrive® Variants

VLT® OneGearDrive® VariantsThe VLT® OneGearDrive® Variants have reached the Limited phase of their lifecycle and are no longer in active production. The discontinued variant with type code element L09 is no longer available for ordering. It has been replaced by the updated type code element L06.