Increased focus on the environmental impact from the marine industry has led new regulation on ballast water treatment taking effect in September 2019. This means that vessel owners have to implement new Ballast Water Treatment Systems (BWTS) to ensure compliance with applicable legislation.

This article explores the challenge of ballast water and the solutions required to comply with the new regulation.

The challenge of ballast water

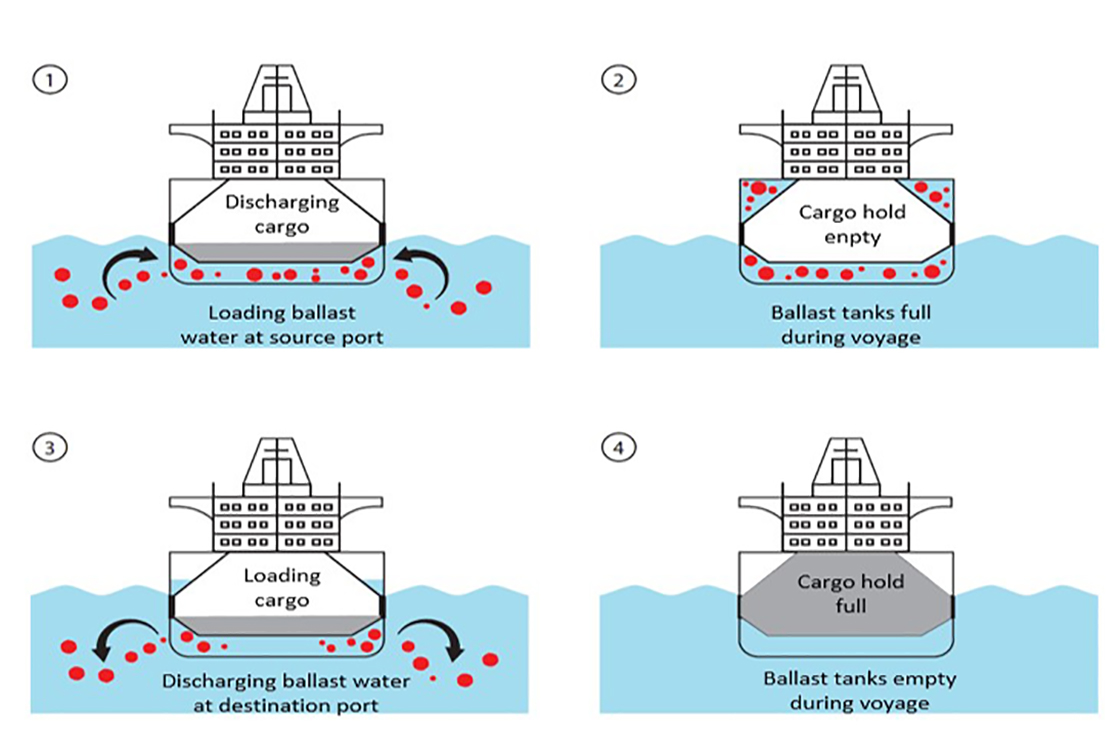

The problem of invasive species carried in vessels’ ballast water is largely caused by the ever-growing trade and traffic across the oceans. The huge amounts of ballast water pose serious ecological, health and economic challenges, as it carries invasive species – bacteria, microbes, plankton, eggs, cysts and larvae - from one part of the world to another.

Facts about ballast water and invasive species

- It is estimated that around 6-10 billion tons of ballast water are moved around the world in ballast tanks every year.

- Every day, an estimated 7,000 marine and coastal species travel unnoticed across the world’s oceans, silently stowed away in vessels’ ballast water tanks.

The effect of the unwanted species has been devastating to local eco-systems. Data shows that the rate of bio-invasions continues to grow at an alarming rate, and new areas are being invaded all the time.

Since the volumes of seaborne trade are expected to continue growing, the problem associated with ballast water may not have reached its peak yet. In order to mitigate the problem, the IMO Ballast Water Management legislation came into force in September 2017.

However, a proposal to delay the requirements for existing vessels was accepted by the Marine Environmental Protection Committee, postponing the enforcement of the new legislation to September 2019.