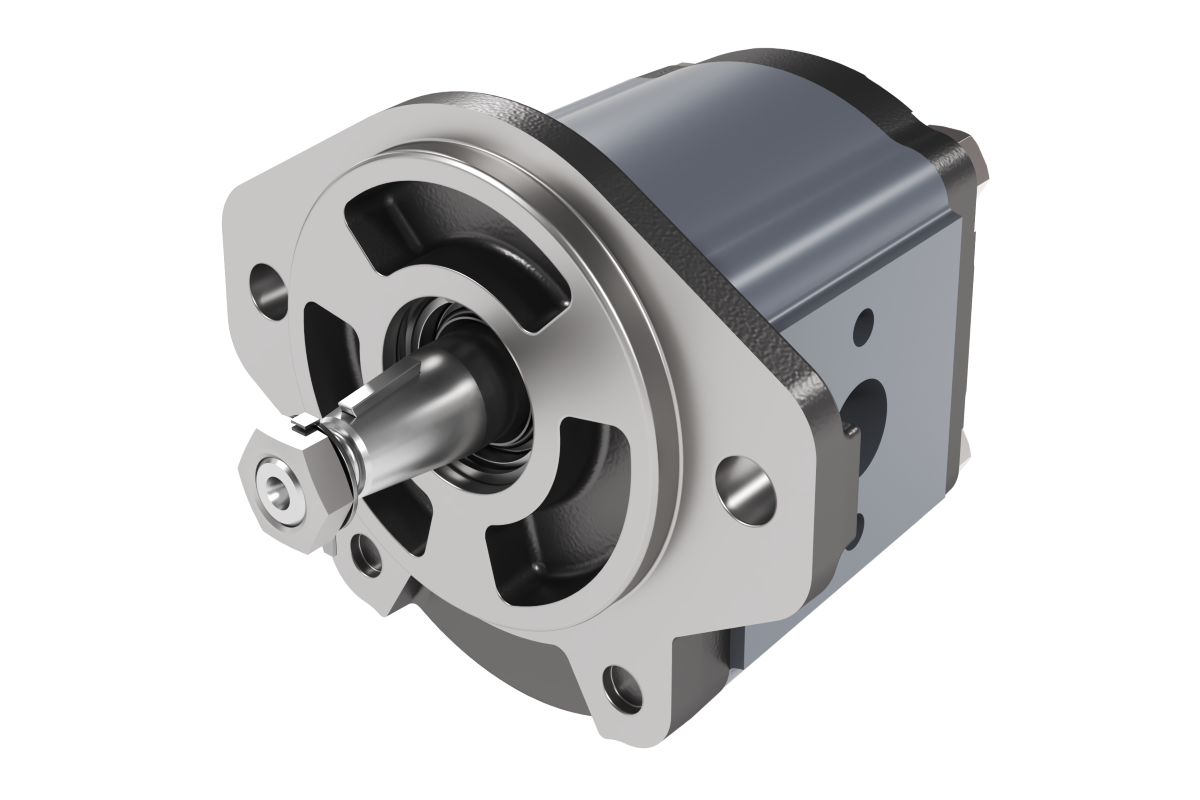

Lumi gear motors

A solid product line for standard applications with unique design featuring cast iron flange and end cover for optimum reliability. Suitable for wide variety of applications that demands standard motor performance.

Features and benefits

Pressure-balanced design, ensuring sealing pressure, adapts automatically to operating conditions for improved overall efficiency and minimum energy losses

Teflon® coated bushings for optimum life under extreme temperature and pressure conditions

Consult your Danfoss representative for available configurations in your regions.

Related products

Coming soon...

Coming soon...

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Service guide | Gear Pumps and Motors Packaging and Recycling Information | English | Multiple | 11 May, 2023 | 428.8 KB | |

| Service guide | Gear Pumps and Motors Packaging and Recycling Information | Italian | Multiple | 11 May, 2023 | 437.3 KB | |

| User guide | Lumi Aluminum Group 2 Motor Technical Information | English | Multiple | 23 May, 2023 | 3.3 MB | |

| Promotion material | Lumi product family flyer | English | Multiple | 05 Feb, 2024 | 2.1 MB |