Supply voltages and power range

- 3 x 200 – 240 V..................... 0.33 HP – 100 HP

- 3 x 380 – 480/500 V.............. 0.5 HP – 200 HP

- 3 x 525 – 600 V.................... 1 HP – 100 HP

- 3 x 525 – 690 V.................... 125 HP – 200 HP

The EZ Everything Drive

For basic drive applications, you don't want to sift through a laundry list of features to customize your drive and wait for delivery; you want an AC Drive with a low number of variants that's easy to stock, ships quickly when needed, and is simple to start up with plug-and-play convenience. We heard you, and that's why we are proud to introduce the VLT® AutomationDrive EZ FC 321. Now available with condition-based monitoring (CBM), this drive offers real-time insights to help predict equipment failures before they happen. For variable speed control of all asynchronous and permanent magnet motors, on any industrial machine or production line, this VFD is packed with standard features right off the shelf with no special configuration or customization required. Save energy, improve flexibility, and optimize processes with this intelligent yet simple variable frequency drive designed for easy stocking and fast turnaround—because every motor deserves the best AC Drive.

Features and benefits

Flexible and expandable: With a flexible modular design, the AutomationDrive EZ FC 321 is packed with standard features which can be expanded with plug-and-play options with additional features and fieldbuses. Safe Torque-Off is a standard safety feature that can be applied through hardwired safety.

Printed circuit board protection: Drives up to 100 HP conforms to class 3C2 (IEC 60721-3-3) as standard. Drives above 100 HP come standard with 3C3.

Robust and reliable: VLT® AutomationDrive EZ FC 321 is a proven performer in all industrial environments and grid voltages, including 690V. Enclosures are available up to NEMA 4X (depending on model), and integrated DC chokes and RFI filters in all models protect installations by minimizing harmonic distortion and electromagnetic interferences. All drives are tested at full-load before leaving the factory.

Easy set up and commissioning: The VLT® AutomationDrive EZ FC 321 is easy to set up and operate via the user-friendly graphical control panel, requires minimal maintenance, and delivers a market leading control solution which provides a fast return on investment with a highly competitive cost of ownership.

Smart Start wizard: Includes groups for several of the most common applications, including conveyors, pumps and fans, and setup with mechanical brake. With the settings to run applications already in place, you can get your machine up and running faster, increasing your productivity.

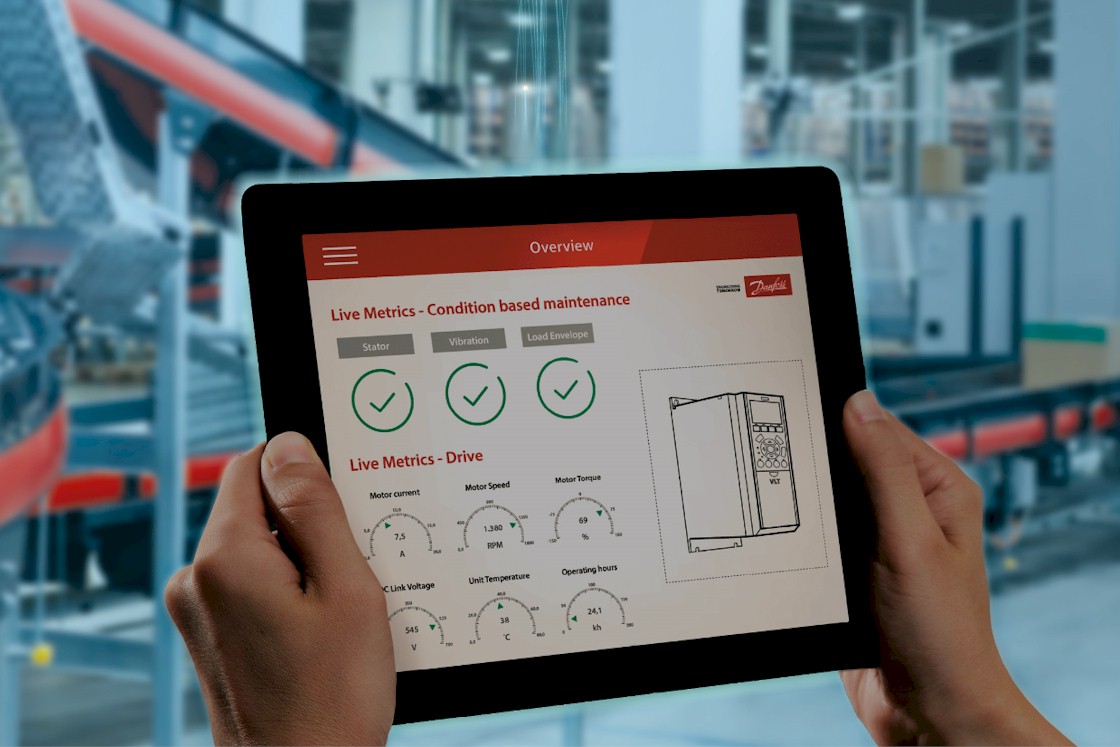

Avoid unplanned downtime with condition based monitoring

Unplanned downtime for any industrial machine or production line, can be catastrophic for essential infrastructure and those who depend on it today. Danfoss technologies empower frontline operators - both on site and remote - to predict unforeseen early failures thereby better planning for maintenance and maximizing uptime. Explore how intelligent VLT® drives solve potentially critical problems in your applications.

Support

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|

Drawings

Your online documentation advantage Danfoss offers parts in IEC & NFPA standards on the Data Portal for the FC 321. NFPA macros dedicated for North America are available on the EPLAN Data Portal, this gives you online access to drawings and documentation which can be dragged and dropped into a project.

Frame Ratings by HP

Contact factory for drives larger than 200HP

Additional mechanical drawings including drawings for Drives with options, electrical drawings and E-Plan files are located below this table under the heading 3D models and drawings.

Frame |

Enclosure |

HP Range |

Base drive dimensions (Inches) |

Mechanical drawing # |

|||||

Chassis |

NEMA 4X / NEMA 12 D-Frame |

230V |

460V |

600V |

Height |

Width |

Depth |

T1 |

|

A2 |

O | 0.5-3 | 0.5-5 | - | 14.7 | 3.5 | 8.1 | MCAD A2 | |

A3 |

O | 4-5 | 7.5-10 | 1-10 | 5.1 | MCAD A3 | |||

A5 |

O | 0.5-5 | 0.5-10 | 1-10 | 16.5 | 9.5 | 7.9 | MCAD A5 | |

B1 |

O | 7.5 - 10 | 15-20 | 19 | 9.5 | 10.3 | MCAD B1 | ||

B2 |

O | 15 | 30 | 25-30 | 26.1 | MCAD B2 | |||

B3 |

O | 7.5-10 | 15-20 | 15.7 | 6.5 | 9.8 | MCAD B3 | ||

B4 |

O | 15-20 | 25-40 | 20.4 | 9.1 | 9.5 | MCAD B4 | ||

C1 |

O | 25-30 | 40-60 | 27 | 12.1 | 12.2 | MCAD C1 | ||

C2 |

O | 40-50 | 75-100 | 30.7 | 14.6 | 13.1 | MCAD C2 | ||

C3 |

O | 25-30 | 50-60 | 21.7 | 12.1 | 13.2 | MCAD C3 | ||

C4 |

O | 40-50 | 75-100 | 26 | 14.6 | MCAD C4 | |||

D1h |

O | 60-75 | 150-200 | 125-200 | 33.2 | 12.8 | 14.9 | MCAD D1h | |

D2h |

O | 100 | 125-200 | 43.6 | 16.5 | MCAD D2h | |||

D3h |

O | 60-75 | 125-200 | 35.8 | 9.8 | 14.8 | MCAD D3h | ||

D4h |

O | 100 | - | 44.2 | 13.8 | 14.7 | MCAD D4h | ||

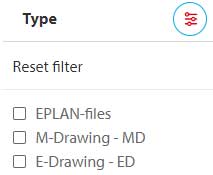

To sort drawings in the 3D models and drawings table below, click on the filter icon to the right of the column title "Type" (shown circled at right):

3D models and drawings

Software

| Type | Software Characteristic | Name | Version | Language | Released | Status | Download | File type |

|---|