Forward. Naturally. With industrial CO₂ refrigeration solutions

How large CO₂ solutions will benefit Industrial Refrigeration

Use the parts designed for the job. Danfoss’ built-for-purpose, built-for-industry, transcritical CO2 solutions ensure your operation is future-proof. The larger components bring unmatched efficiency and simplicity to large systems. Creating a new industrial standard for transcritical CO2 systems.

Transcritical simplified. Start your complexity-free journey in natural refrigerants with Danfoss.

Cool responsibly

Develop your business

Stay supported

Products overview:

SVA-140B Shut-off & FIA 140B Strainer Valves

SNV-ST 140 bar Service Needle Valve

ICMTS 50/80 with ICAD 600A-TS Actuator Motor Operated Valve

ICV 20-80 & ICV Flexline Control valves

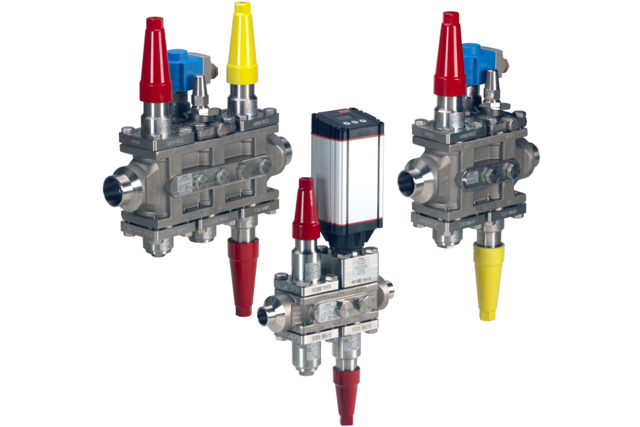

ICF Flexline™ Valve station

LLS 4000 for CO2–coming soon

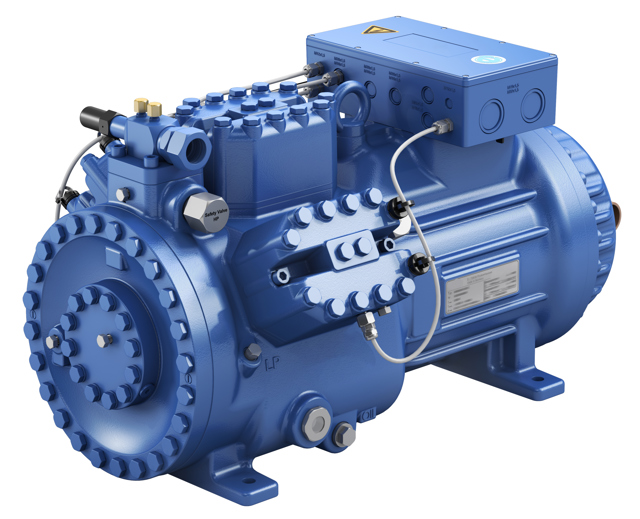

Semi-hermetic CO₂ compressors

Explore the complete range of industrial CO₂ solutions.

Benefit from Danfoss’ two decades of expertise in developing industrial solutions specifically designed for CO2 systems. Our comprehensive portfolio includes a wide array of products meticulously engineered to cater to the demands of sub and transcritical applications.