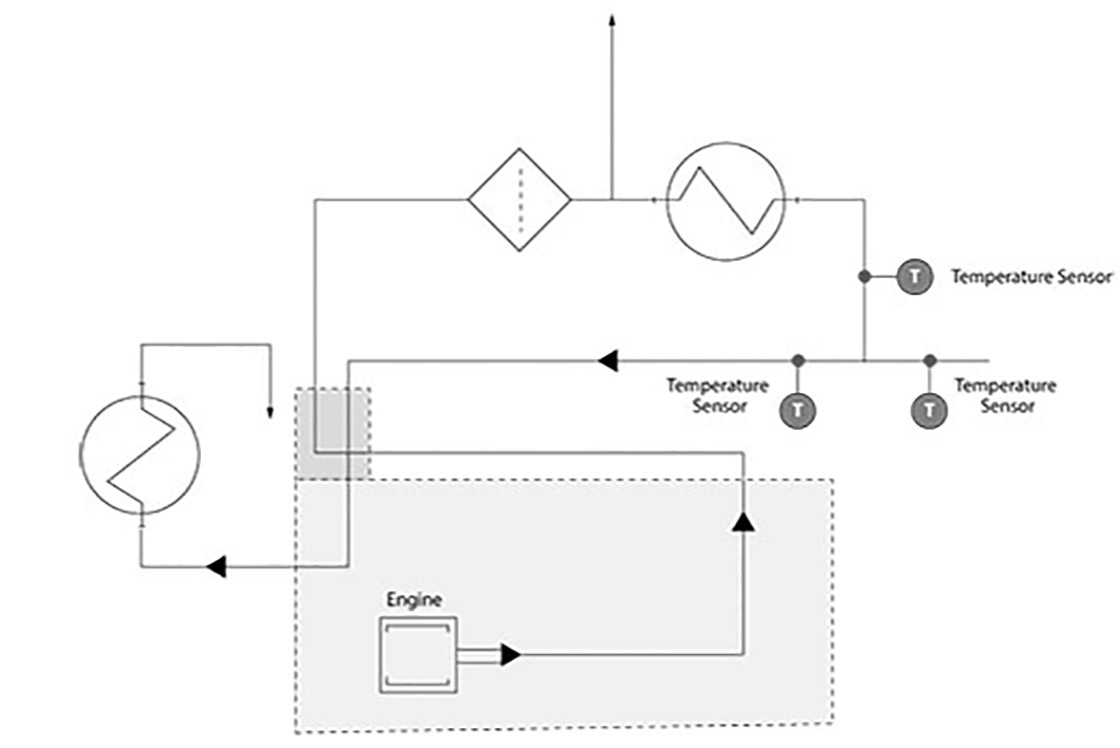

Recirculation of exhaust gas

New engine designs typically use Exhaust Gas Recirculation (EGR) to control NOx emissions. This is done by recirculating exhaust gases back into the combustion chamber to be burned a second time and thereby reduce emission in order to full fill the demands in the Tier IV regulations. Mixing the intake air with exhaust gas in order to cool down the combustion process by several hundred degrees requires accurate temperature measuring of the media.

Typical specifications

- Sensitive element NTC or PTC

- Reaction time in water 1.5 sec

Features and benefits

Fast reaction time to temperature changes

Wetted parts stainless steel

Wide temperature range

Good vibration and shock stability

Wide range of electrical and process connections and insertion lengths

Common temperature sensitive elements, PT100, PT1000, NTC and PTC

Related products

-

if (isSmallPicture) {

MBT 3270, flexible temperature sensor

MBT 3270, flexible temperature sensorThe flexible temperature sensor MBT 3270 can be used in many industrial applications such as: air compressors, mobile hydraulics and exhaust gas return systems.

Contact us

For further information, please contact us.