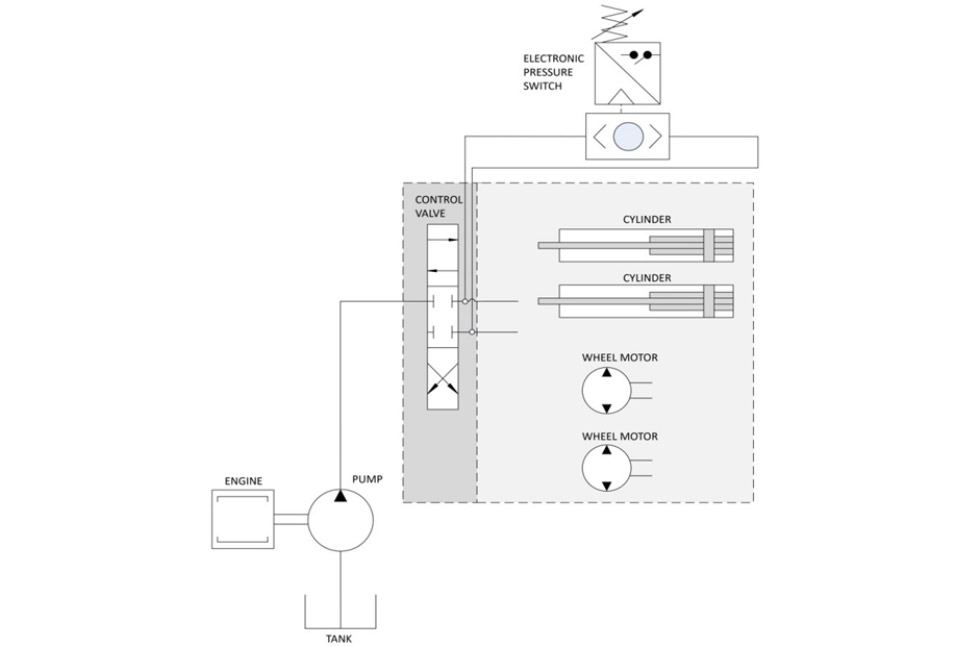

Increase efficiency with automatic idling

In a situation where pump pressure is not needed due to low or no operations, it is important to reduce engine speed until pressure is needed again. Reducing the engine speed in idle situations increases the efficiency of the hydraulic system and thereby reducing fuel consumption and engine noise levels.

Although many auto idle applications are commonly using a mechanical switch, Danfoss recommends using an electronic switch.

Mechanical switches have many problems

- Mechanical switches often leak causing warranty claims

- The electrical contacts can burn out resulting in failure

- The general accuracy is around +/- 5%

- The set point can drift over time

- Over and burst pressure limitation due to moving parts

Typical specifications

- Switch point range: 40 bar

- Pressure range: 0 – 60 bar

- Accuracy: 2% FS

Features and benefits

Electronic pressure switches have 100% welded construction so no leakage possible

No electrical contacts to burn out

Highly accurate – better than 2% typical

No set point drift

Over and burst pressure advantage due to fully welded design

All the advantages from the “world” of transmitters in relation to vibration shock etc.

A more reliable auto idle system

Less wear outs of the switch due to no mechanical parts

Reduced warranty claims

Related products

-

if (isSmallPicture) {

MEP 2200 series, electronic pressure switches, dual output

MEP 2200 series, electronic pressure switches, dual outputMEP 2200 and 2250 are designed for use in severe OEM applications and has excellent long term stability with zero drift. MEP 2250 has a dual output with switch function and an analogue output signal: absolute voltage or 10-90% ratiometric voltage.

Contact us

For further information, please contact us.