Optimize performance, energy efficiency and safety in your refrigeration system

Food safety has top priority among consumers today and tomorrow. Food safety in the dairy, meat, fisheries and other food industries relies on an unbroken and efficient cold chain from field to fork.

Danfoss helps bring food to consumers around the world by providing reliable, precise and efficient refrigeration systems for the food industry.

With Danfoss you will have a trusted partner with experience and know-how related to a wide range of food processing industries, e.g. breweries, dairies, fisheries and the meat industry and for cold storage as well as frozen foods.

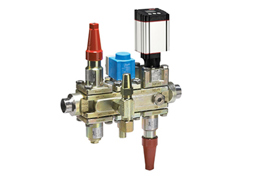

Hygiene is a key word in modern food industry. When hygiene really matters and corrosion is a serious risk due to the harshness of the environment, stainless steel is your ideal choice for refrigeration systems. With the introduction of the Danfoss SVL SS and ICF SS Flexline™ components in stainless steel you will find what you need to obtain optimum hygiene and durable solutions.

The Danfoss valves and filters are designed for the majority of modern refrigerants operating with high pressures, including low GWP refrigerants as for instance CO2 and ammonia.

With Danfoss components you can optimize your refrigeration system as regards performance, energy efficiency and safety. All products come with a wide range of approvals and we can offer you turnkey solutions based on a long history of close cooperation with the food industry.

Features and benefits

Precise temperature control

Stainless steel products for high hygiene and low corrosion risk

Reliable solutions, low operation and maintenance costs

High energy efficiency

Improve defrost performance and reduce energy consumption

The ICFD 20 Defrost Module is a liquid based drain module packaged into our widely acknowledged ICF Valve Station.

Related products

-

if (isSmallPicture) {

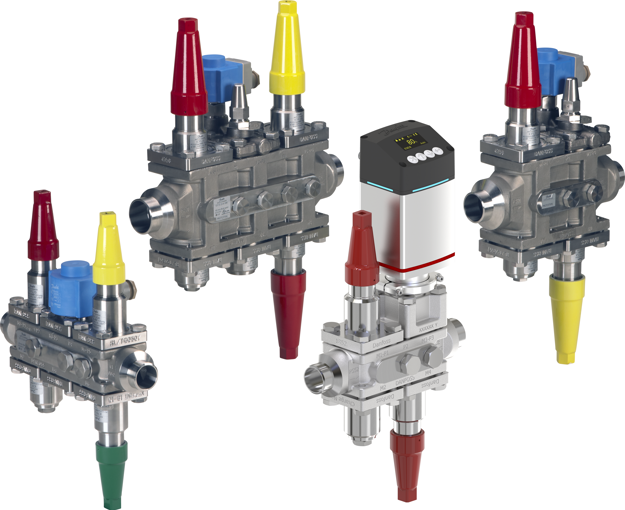

ICF Flexline™ stainless steel valve station

ICF Flexline™ stainless steel valve stationThe ICF SS valve station offer savings in time, space and money compared to control solutions using conventional components.

-

if (isSmallPicture) {

SVL Flexline™

SVL Flexline™SVL Flexline™ product platform targeted to meet industrial refrigeration requirements. The range cover five different functions with just two valve models.

-

if (isSmallPicture) {

SVL SS Flexline™ stainless steel

SVL SS Flexline™ stainless steelThe function modules in the SVL SS platform offer five different functions: shut-off, check/stop, check, regulating and strainer. The new range of stainless steel products is based on the successful modular concept from the products in the Flexline™ family.

-

if (isSmallPicture) {

ICF Flexline™ valve station

ICF Flexline™ valve stationUnmatched freedom is the keyword of ICF Flexline™ valve stations. As part of the Flexline™ platform, these valve stations are based on a unique modular concept.

-

if (isSmallPicture) {

Flexline™ platform

Flexline™ platformThe Flexline™ platform is synonymous with flexibility within industrial refrigeration. Based on a modular design concept, you will experience that each product features a variety of benefits, including easy selection, installation and maintenance.

Case studies

-

if (isSmallPicture) {

NeoCharge boosts safety and efficiency in the Yinli cold storage park

NeoCharge boosts safety and efficiency in the Yinli cold storage parkDiscover how Yinli Cold Storage optimized safety, efficiency, and regulatory compliance with Danfoss NeoCharge. Learn how the solution helped reduce ammonia charge, enhance system performance, and set a new industry benchmark for industrial refrigeration.

-

if (isSmallPicture) {

A cranberry producer in Quebec, Canneberges Drummond Inc., modernizes its pumping system and reduces its carbon footprint with Danfoss solutions

A cranberry producer in Quebec, Canneberges Drummond Inc., modernizes its pumping system and reduces its carbon footprint with Danfoss solutionsCanneberges Drummond Inc. recently completed a major modernization of their pumping system, transitioning from diesel to an eco-friendly, automated solution—thanks to the collaboration of Kopers and 6MGB. By integrating Danfoss VLT® AQUA Drive FC 202, MCT 31 Harmonic Calculation Software, and the VLT® Advanced Harmonic Filter, the cranberry producer achieved: reduced CO2 emissions, improved system reliability, lower operational costs.

-

if (isSmallPicture) {

VFD's are Secret Ingredient for Artisan Cheese Maker

VFD's are Secret Ingredient for Artisan Cheese MakerRecipes for cheese are thousands of years old, passed down through generations and crossing continents —like the Swiss cheese recipes used by Shep Ysselstein, owner and “grand fromage” of Gunn’s Hill Cheese in Woodstock, Ontario, Canada.

-

if (isSmallPicture) {

Huge Water Savings from Food Processor’s Deep Well

Huge Water Savings from Food Processor’s Deep WellFood processing plants require a dependable source of water in large quantities for the washing and rinsing, steaming, cooking, and cooling of food, and during plant sanitation operations. That’s why a large Midwest food processor wanted full control over its water supply by constructing a private water well on its own property. However, what looked like a simple solution was quite complex below the surface — as the well driller discovered when he embarked on the project.

-

if (isSmallPicture) {

Walk-in coolers: a summary

Walk-in coolers: a summaryUse this list to learn what goes into making an efficient walk-in cooler or freezer.

-

if (isSmallPicture) {

Walk-in coolers: temperature controls

Walk-in coolers: temperature controlsThis is the sixth in our series of articles on walk-in coolers and freezers.

As seen throughout this article series, walk-ins are only as good as the components that are included in it. An important piece of the puzzle is the thermostat. A walk-in’s main job, not to put too fine a point on it, is to be cold. Maintaining the internal temperature is critical for meeting food safety standards and keeping product fresh for as long as possible. To do this, while also improving the energy efficiency of the system, a reliable thermostat is required.

Contact us

For further information, please contact us.