G&D Chillers worked with Danfoss, using the microchannel heat exchangers and scroll condensing unit, to make the switch to the high-efficiency refrigerant, R-410A.

Based in Eugene, Oregon, USA, G&D Chillers has developed a reputation for delivering high-efficiency, reliable chillers. Serving breweries, distilleries, wineries, and more, the product designers at G&D Chillers are always on the lookout for components that will enable them to improve the performance, efficiency, and environmental impact of their products. Danfoss was able to offer all three with microchannel heat exchangers and scroll condensing units.

Microchannel means efficiency

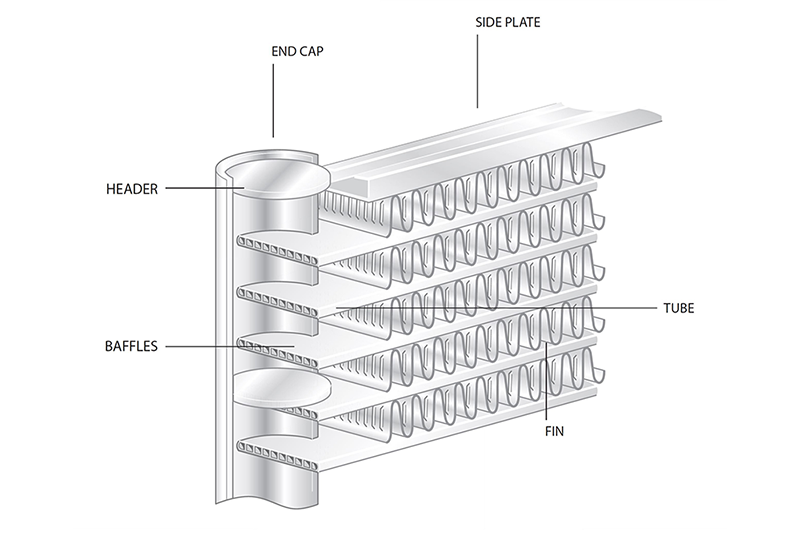

A heat exchanger's job is to transfer heat from one substance to another efficiently and reliably. It is a passive component formed from metal in the shape of a hollow tube or plate that separates substances at two different temperatures. In the case of air-cooled condensers, the two substances are refrigerant and air, where hot refrigerant transfers heat through the metal to the cooler ambient air.

The basic design of a heat exchanger is crucial in determining its performance. Traditional air-cooled condensers, called round tube and plate fin (RTPF), have been made with round copper tubes surrounded by aluminum plate fins—the aluminum fins increase the surface area to improve heat transfer efficiency.

Alternatively, microchannel heat exchangers (MCHEs) are completely aluminum and feature flat tubes and fin arrays in a corrugated profile. The tubes are flat to reduce aerodynamic drag, resulting in up to 10% greater efficiency. The multiport design creates a smaller internal diameter than RTPF coils, which improves heat transfer, decreases weight by up to 60%, reduces refrigerant charge by up to 70%, and shrinks the component’s footprint.

With all of these advantages, it’s easy to see why G&D Chillers would choose the MCHE over the RTPF as their preferred type of air-cooled condenser, but there was also another reason: MCHE can be used with nearly any refrigerant currently available, including high pressure R-410A.

Give the people what they want

R-410A is one of the most popular refrigerants in the world, especially for chillers. Since many of their customers already use or are familiar with R-410A, G&D Chillers designs many of their chillers with the prevalent refrigerant. And because MCHEs are compatible with R-410A, they make it easy to adapt other components—most notably, condensing units.

Tim Hubbard, a design engineer at G&D Chillers, said, “Our most popular chillers are powered by Danfoss condensing units. We also offer large capacity maximum efficiency chillers using Danfoss scroll compressors with R-410A. However, at a smaller scale our R-410A options were limited. Because we know Danfoss produces reliable condensing units, and we’re familiar with their high-quality scroll compressors rated for R-410A, we asked if they could provide us with a custom solution to fulfill this need.”

The condensing unit that G&D Chillers was interested in was essentially the Danfoss Optyma™ Slim. Unfortunately, the Optyma Slim isn’t available for use with R-410A. Or rather, it wasn’t. Thanks to the flexibility of the MCHE, adapting the Optyma Slim to use R-410A was fairly easy—it just required finding the right compressor.

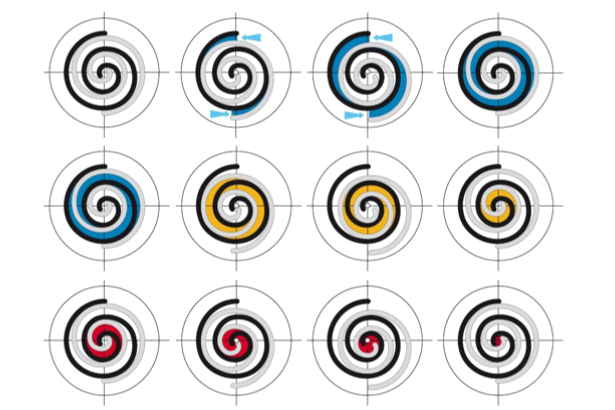

The compressors used in the standard Optyma Slim are not designed for R-410A. However, the DSH scroll compressor is and, as an added advantage, it includes intermediate discharge valve (IDV) technology. As with all scrolls, two spiraled strips of metal—one fixed and one orbiting—compress refrigerant by progressively creating three pockets: an outer pocket, an intermediate pocket, and a final pocket at the center where discharge conventionally takes place.

Traditionally, the refrigerant must be fully compressed in the intermediate pocket before it is discharged out of the center pocket. IDV technology places discharge valves in the intermediate pocket of the compression cycle. These additional discharge valves improve efficiency as the ambient temperature drops or during part-load conditions, as the compressor does not need to work as hard to deliver the same cooling capacity.

A perfect pair

By adapting the Optyma Slim platform with its MCHE condenser to use the R-410A compatible DSH scroll compressor featuring IDV technology, Danfoss and G&D Chillers had found the perfect solution. Pairing the intrinsic high efficiency of the Optyma Slim with the performance of R-410A, G&D Chillers is able to offer their customers the best possible chilling experience.