Fixed orifice devices are ideal throttling devices if conditions never change. If the load on the system is constant and the ambient temperature remains steady, then a simple capillary tube or piston would be preferable to an adjustable orifice device like a TXV. However, outside of a laboratory, static conditions are simply not realistic.

Seasonal temperature changes have a profound effect on system performance, as does increasing the heat load inside. For example, summer brings warmer weather, which increases the condensing pressure of the refrigerant in the air conditioner. Since the throttling device acts as a type of dam within the system, a fixed orifice device will not open more when the load increases to allow more refrigerant through, which increases the superheat on the compressor. Additionally, once the load decreases (perhaps at night), the back pressure drops, which significantly increases the risk of liquid refrigerant making it to the compressor, damaging it.

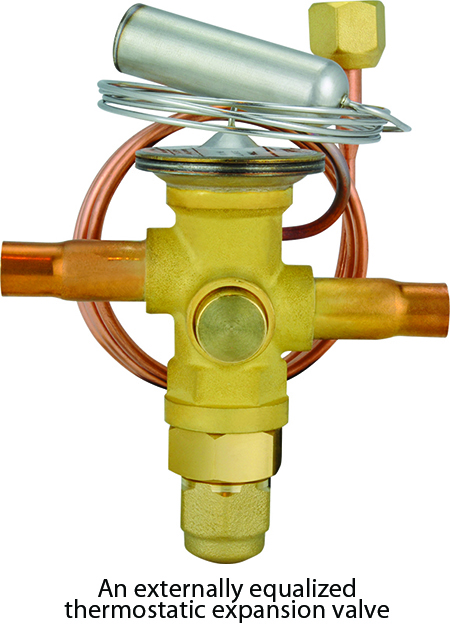

A TXV will modulate open or closed based on changing conditions and will adjust to maintain a constant superheat. This in turn ensures that efficiency is optimized and the compressor is protected against damage from liquid refrigerant. Unless the system is in a laboratory and only tested under one condition, a TXV will always be the better choice.

EEVs are top-of-the-line throttling devices. While TXVs are purely mechanical, EEVs can be programmed to work with the other components in the system, allowing it to further optimize performance and efficiency. While EEVs can outperform TXVs, the gains often do not justify the much higher cost. A standard TXV can increase efficiency versus a fixed orifice device by about 30% for only a small increase in cost, whereas an EEV will be significantly more expensive and there is no guarantee that it will improve efficiency.

One reason for the greater expense is that EEVs need additional components to work properly, including a controller and sensors. While TXVs have been engineered to be self-contained, EEVs are best seen as part of a greater whole, operating according to data the sensors collect and the commands the controller and its underlying software sends out. And while a TXV can be a drop-in replacement for a piston or capillary tube, the same cannot be said for an EEV.

Systems that require exact precision—such as those with variable-speed compressor technology, where the load, ambient conditions, and compressor mass flow go through high rates of change—will benefit from having an EEV and complimentary components. However, an EEV is only as good as the algorithms that dictate its operation, so most owners cannot justify such a significant cost increase when no return is guaranteed.

TXVs are not just about efficiency and cost-consciousness—another important factor is reliability. The power element is the most common part of a TXV to fail, so having one that is made from high-quality materials will extend the life of the valve. Laser-welded, stainless steel power elements offer the longest life possible, with many guaranteed tested life cycles above 200,000 cycles.

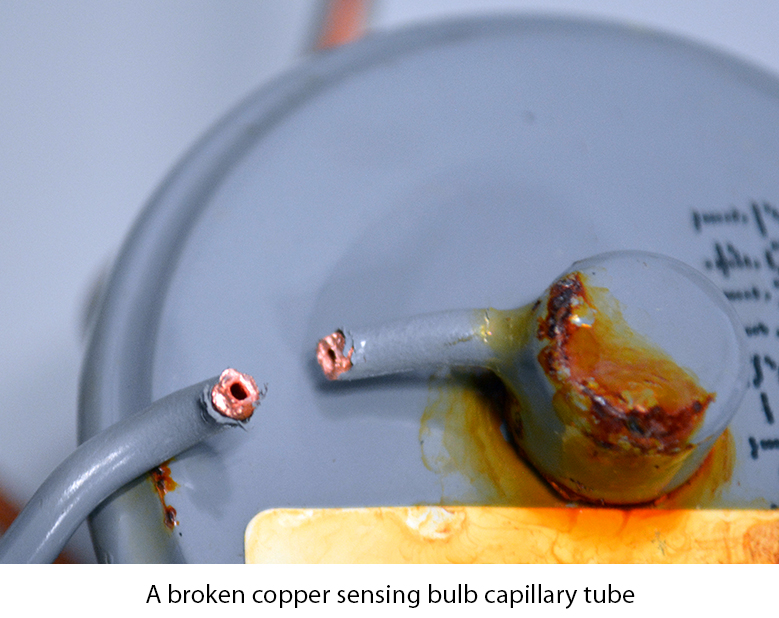

Another common point of failure is the sensing bulb capillary tube. Once again, stainless steel offers flexibility and durability not available with other metals. Stainless steel sensing bulb coils can be bent and flexed over and over without fear of cracking, as is typical with copper capillary tubes.

Another common point of failure is the sensing bulb capillary tube. Once again, stainless steel offers flexibility and durability not available with other metals. Stainless steel sensing bulb coils can be bent and flexed over and over without fear of cracking, as is typical with copper capillary tubes.

Finally, TXVs are often used to upgrade a system from a fixed orifice device, so a TXV that is easy to install is most ideal. Retrofitting a fixed orifice device system with a TXV is easy, especially when the valve comes packed with the most common fittings to attach to the evaporator distributor, like flare, Aeroquip, or Chatleff, making upgrades hassle-free.

Simply put, TXVs are so popular because they offer efficiency and affordability in one reliable device.