Our SONDEX® plate and shell heat exchangers (SPS) combine the strengths of both shell and tube heat exchangers and plate heat exchangers, retaining the high working pressure and temperatures of the former coupled with the high efficiency of the latter. A “best of both worlds” solution, our plate and shell heat exchangers provide unmatched performance for a wide range of applications, particularly vapor condensation duties.

What does that mean for you?

Featuring fully welded plate packs, our plate and shell heat exchangers are well-suited for handling aggressive media as well as high pressure and temperatures. Using plate technology instead of tubes, the high heat transfer coefficient allows our engineers to reduce the surface area needed for optimal performance. The result is a compact heat exchanger that outperforms its shell and tube counterpart and can achieve much closer temperature approaches while requiring far less space and being much lighter in weight.

The use of plate technology also alleviates a common challenge of shell and tube heat exchangers; fouling. With an increased level of turbulence, the risk of fouling is greatly reduced as a turbulent flow prevents particles and film from clogging the heat exchanger.

Compared to shell and tube heat exchangers, SONDEX® plate and shell heat exchangers are very economically competitive solutions that offer a fast return of investment. The compact size, light weight, and low installation costs keep the initial purchase price to a minimum, especially if exotic materials are required. Infrequent need for maintenance and energy optimized performance curbs the ongoing operational expenses.

Solving flow rate differences

Certain applications work with different flow rates of the two media and can be very challenging to solve optimally. Our asymmetric plate pattern range is perfect for such applications, as they have narrow channels on one side and wide channels on the other. This design enables the heat exchanger to easily handle differing flow rates and allows us to use the pressure drop in the most efficient manner resulting in higher turbulence, greater heat transmission, and more cost-effective operation. Asymmetric patterns are the go-to solution for handling high-viscosity media or condensing gas in large volumes.

Micro plate technology

Our heat exchangers with the new state-of-the art Micro Plate™ technology feature next-generation efficiency and performance – giving you more from your district heating and cooling applications.

SONDEX® Free flow patterns

The SONDEX® Free Flow pattern is designed to treat media that is unsuitable for regular heat exchangers due to high viscosity, fiber and particle contents, or considerable risk of fouling.

Applications

- HVAC industry

- Marine/offshore industry

- Dairy/food/beverage industry

- Sugar industry

- Biogas industry

- Refrigeration industry

- Pulp and paper industry

- Heavy industry

- Mining industry

- Petrochemical industry

- Chemical industry

- Condensation

- Steam heating

- Oil coolers

- Gas heaters/coolers

Technical specifications

- Connections from DN25 to DN300

- (Frames designed according to FEA and PED 2014/68/EU (EN13445) and ASME sec VIII, Div. 1 construction standards)

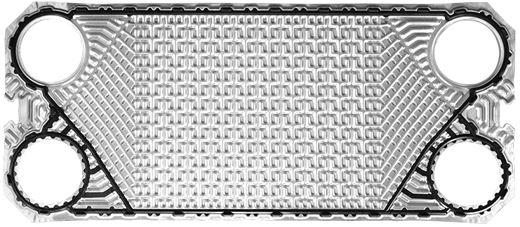

- Plates made from AISI 304/316, titanium. Other materials available upon request

- Shell materials: Carbon steel, stainless steel

- Working pressure up to 40 bar (580 psi)

- Working temperature 10 °C up to 250 °C (50 °F to 482 °F) for bolted types (up to 400 °C (752 °F) for the fully welded types)

Features and benefits

Very adaptable heat exchanger. An excellent choice for handling condensation duties, especially duties without condensate sub-cooling. They are also perfect steam heaters of clean fluids, demineralized water, and clean thermal oils.

The heat exchanger is designed to be highly resistant to thermal shocks as well as thermal and pressure fatigue making it very well-suited for cyclic duties and other duties with sudden, large fluctuations in temperature.

Available in both bolted and fully welded designs. The fully welded types can handle higher temperatures and pressure levels than the bolted types, but cannot be opened for cleaning. This can instead be done with CIP (Cleaning in Place) systems.

Working principle of a SONDEX® plate and shell heat exchanger

SONDEX® plate and shell heat exchangers have a fully welded plate pack, making them very well-suited for challenging applications.