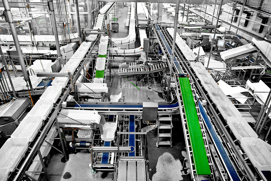

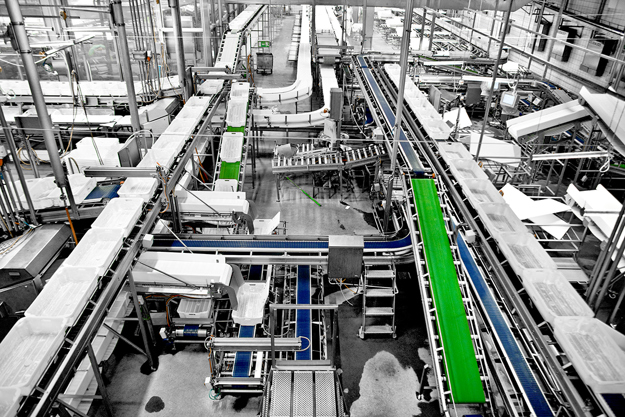

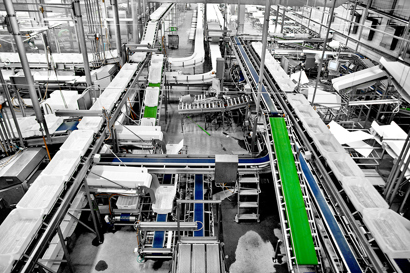

Maximize conveyor uptime

Conveyor applications need to perform reliably to ensure maximized uptime and the lowest cost of ownership. VLT® drives provide optimized motor control and, for example, improve quality and product consistency, minimize waste and optimize whole filling and packaging area. They are often regarded as the preferred brand within many of these industry sub-segments.

Highly sensitive products, such as still bottled water and alcohol-free beer or new materials for packaging and bottles, raise the hygiene requirements in production plants. In addition to the Machinery Directive and national standards, hygiene regulations are becoming increasingly important for plant design and drive engineering. Danfoss is unique in offering IPA certified solutions and products for use in hygiene-critical sub-systems.

The VLT® FlexConcept® is intended for use in hygiene-critical sub systems. The motors are certified by the Fraunhofer Institute IPA for direct use in cleanrooms and aseptic production plants.

The system simplifies project planning, installation, commissioning and maintenance, especially for conveyor systems. System variants can be reduced by up to 70% so users benefit from maximum flexibility with a minimum number of modules, including motors and drives which offer a unified operating concept and standardized functionality regardless of whether the system is implemented with a centralized or decentralized structure, in dry, wet or aseptic areas.

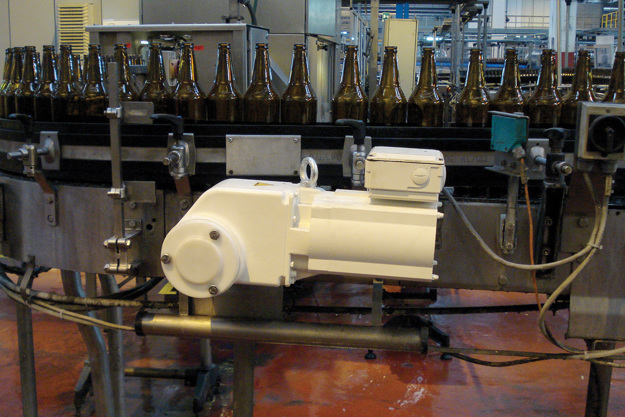

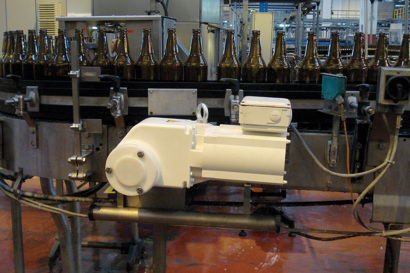

Read how Molson Coors bottling plant generated savings with VLT® FlexConcept

Breweries consume a lot of energy in running their processes. At Molson Coors’ Borsodi Brewery in northeastern Hungary, an upgrade of the gear motors on a glass bottle filling line has resulted in energy savings of 33-42%.

Contact us

For further information please contact us

Case studies

-

if (isSmallPicture) {

Danish Crown super slaughterhouse saves 30 tEUR annually on motor replacement

Danish Crown super slaughterhouse saves 30 tEUR annually on motor replacementThe 1,000 VLT® drives installed throughout the plant control everything from simple conveyor belts to more advanced applications.

-

if (isSmallPicture) {

Bottling is more competitive when it is sensorless

Bottling is more competitive when it is sensorlessTo achieve higher productivity and energy efficiency on two new bottling lines, Tavina chose the Danfoss VLT® FlexConcept drive system.

-

if (isSmallPicture) {

VLT® Midi Drive optimizes efficiency in Brazilian biscuit factory

VLT® Midi Drive optimizes efficiency in Brazilian biscuit factoryOriginal equipment manufacturer, Ariete, delivers quality and a competitive edge using the same drive for different applications.

-

if (isSmallPicture) {

Coca-Cola FEMSA enjoys more uptime with DrivePro®

Coca-Cola FEMSA enjoys more uptime with DrivePro®Since investing in DrivePro® services, the bottling lines at Coca-Cola FEMSA in Brazil have dramatically improved in reliability and availability.

-

if (isSmallPicture) {

Peroni wins >30% in conveyor efficiency

Peroni wins >30% in conveyor efficiencyPeroni Brewery wins at least 30% better conveyor belt efficiency in a bottling line upgrade with VLT® FlexConcept®.

-

if (isSmallPicture) {

High production throughput for Reicholzheim

High production throughput for ReicholzheimVLT® Midi Drive FC 280 helps sweet grapes make sweet wine.

Products

-

if (isSmallPicture) {

VLT® AutomationDrive FC 301 / FC 302

VLT® AutomationDrive FC 301 / FC 302The VLT® AutomationDrive FC 301 / FC 302 is designed for variable speed control of all asynchronous motors and permanent magnet motors. It comes in a standard version (FC 301) and an advanced high dynamic version (FC 302) with additional functionalities.

-

if (isSmallPicture) {

VLT® Midi Drive FC 280

VLT® Midi Drive FC 280FC280 provides precise and efficient motor control for machine builders in the food and beverage, material handling and processing industries.

-

if (isSmallPicture) {

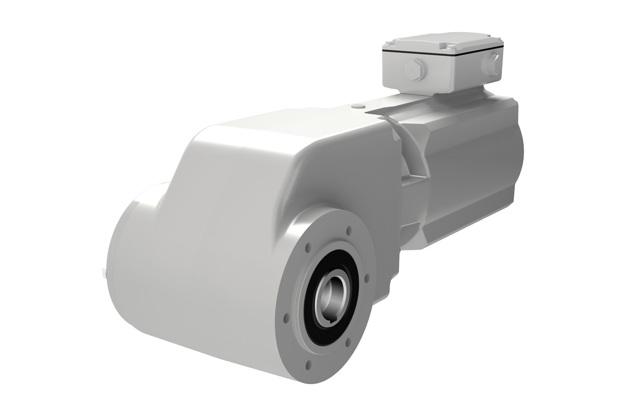

VLT® OneGearDrive®

VLT® OneGearDrive®A highly efficient combination of a permanent magnet motor and optimized bevel gearing.

-

if (isSmallPicture) {

VLT® Decentral Drive FCD 302

VLT® Decentral Drive FCD 302Thanks to its rugged design, the FCD302 drive can be mounted close to motors in demanding applications.