Impact on OPEX

How does network quality affect operating costs? Poor power quality results in unnecessarily high electricity bills.

Check the electricity bill:

- You may be surprised to find out how much you pay for poor power quality that does not contribute to operating your facility or plant, it just costs you money.

- The cost of distortion power (kVAr) can be higher than the power being used to actively run the plant (kVA or kW).

Contact us for advice

Energy is wasted by electrical systems that are distorted with harmonics and poor power factor. Harmonic distortion and poor power factor costs money, either directly or indirectly.

Good to know:

- You can reduce greenhouse gas emissions and energy costs by using equipment designed to mitigate or eliminate harmonic distortion

- Modern drives (VSDs) and associated filters can manage the power distortions in your systems to remove these expensive problems

- Even better, these drives can reduce CAPEX on purchases and operational expenditure on networks by 10-25%. Consider drives early in project design to optimize costs as well as greehouse gas emissions.

Talk to the experts at Danfoss to get the best advice on balancing expenditure with system efficiency. Contact us here for advice.

Reducing the harmonic footprint increases efficiency of the power grid and reduces losses in transformers, generations, cables, and switch gear.

- Reducing harmonics improves efficiency no matter which harmonic mitigation equipment is used.

- So, why not use the most optimal mitigation technique possible, and maybe only have it running when needed?

- In this way, you can significantly reduce the energy bill - most likely even at a lower investment.

Danfoss can help you find the best method to save energy costs related to harmonics at your specific site. Have questions? Contact us for expert advice.

Carbon accounting

Harmonic distortion and harmonic distortion generators causes poor network quality which is a big factor in wasting greenhouse gases (GHGs).

We can help you to optimize GHG accounting with good advice on

- Which equipment to buy

- What equipment to operate, and how

- The devices you recycle

Are you engaged in carbon accounting or GHG calculations to meet GHG accounting standards such as the Greenhouse Gas Protocol? Do you set net zero targets and have ambitions to make your company more environmentally friendly?

- Poor control and poor network quality play a big factor waste of GHGs and GHG emission levels

- Did you know that environmental targets can be achieved much more quickly by designing the electrical and control system carefully, including the use of drives (VSDs)?

- Drives have a major impact upon Scope 1, 2 and 3 greenhouse gas emission targets, and these devices can play a major role in decarbonizing your plant. They are suited for optimizing new projects or upgrading and improving existing installed equipment*

How do drives (VSDs) affect greenhouse gas accounting?

Upstream emissions (Scope 3.1)

Designing early for low total harmonic distortion mean smaller transformers, generators and switchgear components, which contain less materials, are lighter to transport and take less energy to manufacture.

Less fuel and energy is needed to operate the plant when VSDs are employed as widely as possible, compared with poorer control strategies, offsetting initial capital cost. This results in fewer greenhouse gas sources.

Downstream emissions (Scope 3.11)

VSDs ensure minimum waste from the plant due to minimized breakdowns and downtime. Drives offer 10-year operating life without maintenance, and fewer plant breakdowns with smart condition-based monitoring to protect driven loads and the wider process.

When smaller high-capital equipment is purchased in the beginning, there is less waste to recycle when plant reaches end of life. Altogether, this reduction supports reduced carbon emissions.

Indirect emissions (Scope 2)

VSDs always control the process to the optimal level for efficiency , throughput and quality. Controlling fans, pumps, and compressors brings the highest energy saving (2-60%), although conveyors and cranes and other applications also benefit greatly. Connect VSDs with motors of the highest efficiency class to maximize the benefits of both technologies, to reduce carbon emissions and other greenhouse gas emissions.

Direct plant emissions (Scope 1)

VSDs ensure the plant operates and produces output most efficiently, ensuring lowest possible direct emission from the processes. Emissions can be measured and connected back to the VSD to manage setpoints of emissions directly and reduce waste during the manufacturing processes. VSDs can be used to treat unwanted greenhouse gas emissions emissions to reduce their impact.

Explore more about harmonic mitigation

Case studies

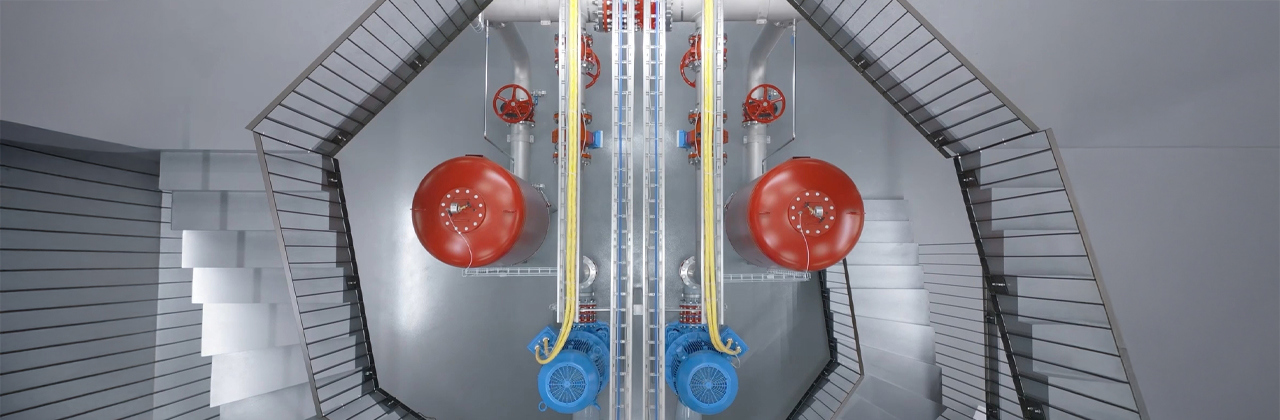

How a new water pumping station keeps supply flowing in Bern

SWITZERLAND: The Wehrliau pumping station in Bern delivers up to 1.20 M liters of drinking water hourly. iC7 drives play a key role in ensuring reliable supply.

Read the case story

How does Beat the Storm deliver more fun for less CO2?

DENMARK: Universe Science Park saves on both power bill and emissions for its wind tunnel attraction “Beat the Storm”, with the intelligent VLT® HVAC drive.

Read the case story

Danfoss compressor control ensures optimal comfort for hospital patients and staff

In the University Medical Centre (UMC) Ljubljana air conditioning system, Danfoss drives with integrated filters ensure low harmonic distortion, with maximum THDi of 5%.

Read the case story

How did Sincrondraiv SRL improve irrigation pumping efficiency by up to 40%?

ROMANIA: Digitizing irrigation systems helps farmers achieve better harvests. Pumping stations now use 30-40% less energy and use water more efficiently too.

Read the case story

Accurate control of CT Offshore’s ROV trencher

VLT® AutomationDrive FC 302 and VLT® Soft Starter MCD 500 provide quick and accurate control of high- and low-pressure seawater pumps on the remotely operated trencher laying HVAC subsea cables.

Read the case story

Rock-solid reliability underpins sustainable aquaculture at Nordlaks

NORWAY: VLT® AQUA Drive FC 202 ensures dependable uptime with stringent harmonic compliance at Nordlaks Smolt AS.

Read the case story

Jersey Water desalination plant boosts efficiency by 38%

UNITED KINGDOM: Jersey Water chose VLT® AQUA Drive from Danfoss when needing a major upgrade at its La Rosière desalination plant.

Read the case story

Contact us

Reduce risk

Are you willing to risk unnecessary downtime?

Have you experienced

- Unplanned production stops?

- Expensive loss of production due to downtime?

- Failures to critical equipment “out of the blue”?

- Motors and driven loads failing?

The cause is often poor network quality due to harmonic distortion. Harmonic distortion causes damage to critical equipment leading to failures.

Adding drives (VSDs) to your system can improve network quality, massively reduce energy consumption, and manage driven loads to ensure breakdowns are minimized with good maintenance planning. Managing harmonic distortion using drives brings stability to the electrical grid and reduces outages.

The whole topic of network quality and how it impacts greenhouse gas accounting can be daunting. Luckily you don’t need to be the expert. Danfoss experts stand ready to support your business with expert advice and VSD solutions for energy savings and cost-effective harmonic mitigation.

Contact us for advice.