DST GS and DST G-series sensors

DST GS and DST G-series gas detection sensors feature a revolutionary inverted design, which protects the sensor in harsh environments, supporting 5 different A2L refrigerants with the option of additional refrigerants added upon demand. Using Thermal conductivity, a field proven technology, our sensors meet the requirements for HVACR equipment.

With patented top-down design that protects sensors from all common contaminants you can get 15+ years of performance as estimated per our extensive internal testing.

Prioritize safety, reduce maintenance and ensure supply

Proven high-speed thermal conductivity sensors delivers excellent response time, ensuring maximum safety for users and equipment. And as a leading tech developer with in-house production, Danfoss offers a resilient supply chain, ensuring to meet your demands and maintain a steady delivery to support your business growth.

Features and benefits

-

Patented, compact & robust design

High IP66 rating in a compact casing (DST GS-series only). -

Versatility

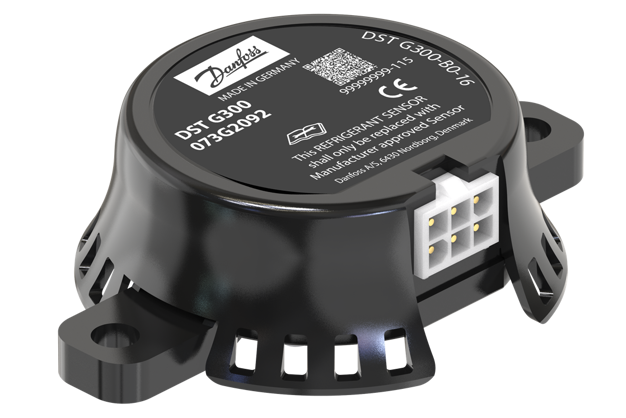

Flexible design, suitable for applications use with R454B and R32 refrigerants (DST G200 only) and with R454A, R454C and R455A (DST G300 only). -

Rapid and Accurate Leak Detection

Compensated over full range of temperature humidity and pressure ranges. -

Eliminate False Alarms with Dewpoint Avoidance

Dewpoint monitoring and heated enclosure prevents condensation in the housing. -

Immune to Dust, Oil and Water Spray

Strategic, patent-pending sensor positioning using diffusion flow principles protects sensor from exposure. -

UV Protected

All exposed materials are impervious to sustained UV exposure. -

No Field Service Requirements

Permanent factory calibration. No field adjustments or re-zeroing during 15+ year life as estimated per our extensive internal testing. -

Minimized “Silent” Failures

Robust “full signal chain” diagnostics check for faults and integrity of signal chain. -

Easy System Integration

Flexible hardware and software to customer’s application specifications.

Articles

This whitepaper answers two key questions: why thermal conductivity is the best technology for quickly and accurately detecting A2L gas leaks and how product design impacts a thermal conductivity sensor’s effectiveness and durability.

Download white paper

Applications

The DST GS and DST G-series sensors are designed with focus on:

-

HVAC

Computer Room Air Conditioners (CRAC) units, Residential and Commercial Heat Pumps, Rooftops, Transport A/C, and A/C Scroll chillers. -

Commercial refrigeration

Cold rooms, Food retail and Food service, Commercial refrigerators and freezers, display cabinets, compressor racks/packs. -

Coil manufacturers

System builders requiring a dual refrigerant gas sensor. -

Other industries

With applications using A2L refrigerants.

Fact box: Bringing the right gas sensor technology to market

Since the start of the refrigerant transition, our multidisciplinary team of experts has worked together with our customers to explore and test various gas sensing technologies.

We wanted to combine our 55+ years of experience in developing HVACR applications, with the latest research in this area, so we could base our solution on the technology and product design that would deliver the best results for our customers’ systems. Our TC sensor is the result of this collaboration, and it also marks the first step in our gas sensing journey. The next step in the journey will take us to Monterrey, Mexico, where we’re establishing a manufacturing footprint at our Danfoss campus. This location places us in proximity to our customers and will make it easier for us to partner with them to develop new gas sensing technologies. Our local presence will also improve speed-to-market and lead times and reduce transport emissions, so we can effectively meet the market’s increasing demand for sensor technology and support our customers’ growth.

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Data sheet | A2L Gas Sensor - Compact design DST, GSxx series | English | Multiple | 27 Oct, 2025 | 701.7 KB | |

| Data sheet | A2L Gas Sensor, Types DST G54A, DST G54C, DST G55A | English | Multiple | 27 Oct, 2025 | 801.0 KB | |

| Data sheet | A2L Gas Sensor, Types DST G54B, DST GR32 | English | Multiple | 24 Oct, 2025 | 846.0 KB | |

| Installation guide | A2L Gas Sensors, Relay, MODBus and Dual Output | French | Multiple | 13 Nov, 2024 | 418.8 KB | |

| Installation guide | A2L Gas Sensors, Relay, MODBus and Dual Output | English | Multiple | 22 Aug, 2023 | 425.0 KB | |

| Brochure | DST G-series A2L refrigerant detection sensors brochure | Spanish, Castilian | Spain | 11 Mar, 2025 | 1.0 MB | |

| Brochure | DST G-series gas sensors brochure | English | Multiple | 06 Feb, 2026 | 509.2 KB | |

| Data sheet | DST G200 | English | Multiple | 24 Oct, 2025 | 948.1 KB | |

| Brochure | DST GS-series gas sensors - the compact and resistant solution for gas detection | English | Multiple | 12 Sep, 2025 | 995.2 KB | |

| White paper | Thermal conductivity: the best technology for A2L HVACR market | English | Multiple | 16 Jan, 2024 | 3.4 MB |

Approvals

-

CE marked

-

RoHS compliant

-

UL 60335-2-40

-

UL 60335-2-89

Approval Certificates

| Type | Name | Approval authority | Language | Valid for | Download | Expiration date | File type |

|---|---|---|---|---|---|---|---|

| Electrical Safety Certificate | CSA 80218837 | English | Multiple | 182.6 KB | |||

| EU Declaration | Danfoss EU-UK 073R0000.02 | English | Multiple | 766.2 KB | 01 Sep, 2030 | ||

| Export Control Declaration | Refrigerant Leakage Sensor | English | Multiple | 178.3 KB | |||

| Electrical Safety Certificate | UL E534311-20240718_20240722 | English | Multiple | 261.2 KB |

Highlighted products

The latest addition is the DST GS-series gas sensors, developed to detect R454B, R32, R454A, R454C and R455A refrigerant type that meet the performance and reliability required to carry the company name. These sensors meet the requirements of UL 60335-2-89 for refrigeration equipment and the requirements of UL 60335-2-40 for HVAC equipment.

New addition to the DST G-series is the DST G4ze gas sensor, developed to detect R1234ze refrigerant type, perfect for HVAC&R system builders looking for a reliable and accurate gas sensor. These sensors meet the requirements of UL 60335-2-40 for HVAC equipment.

The latest addition to the DST G-series is the DST G300 tri-refrigerant gas sensor, developed to detect R454A, R454C and R455A refrigerant type, perfect for refrigeration system builders, looking to reduce complexity while gaining flexibility in building A2L refrigerant compatible systems. These sensors meet the requirements of UL standards for refrigeration equipment.

The latest addition to the DST G-series is the DST G200 dual refrigerant gas sensor, developed to detect for R454B and R32 refrigerant type, perfect for coil manufacturers and system builders, looking to reduce complexity while gaining flexibility in building A2L refrigerant compatible systems. These sensors meet the requirements of UL standards for HVAC equipment.

Using field proven technology, Danfoss Sensing Solutions has developed the DST G54A, DST G54C and DST G55A A2L refrigerant gas sensors for R454A, R454C and R455A refrigerant type that meet the performance and reliability required to carry the company name. These sensors meet the requirements of UL 60335-2-89 for refrigeration equipment.

Using field proven technology, Danfoss Sensing Solutions has developed the DST G54B and the DST GR32 A2L refrigerant gas sensor for R454B and R32 refrigerant type that meet the performance and reliability required to carry the company name. These sensors meet the requirements of UL 60335-2-40 for HVAC equipment.

Related applications

Your refrigeration system is the natural place to look for energy efficiency gains. To unlock that potential, you need a controller, expansion valve, and high accuracy sensors that are smart enough to make the technology work together—and a system manager that can help you see and control the bigger picture.

Air conditioning systems with precise close control for high reliability, better humidity and temperature control in IT cooling, in server rooms or data centers.

Related solutions

Danfoss air conditioners are durable, energy efficient and affordable, you will find solutions for residential and commercial air conditioning applications.

As a leading supplier within commercial refrigeration our extensive product range enables us to support solutions for anything from transport refrigeration to speciality cooling.

The need for supermarkets to improve energy efficiency, reduce food loss and minimize carbon footprint is higher than ever before. In cooperation with a Danish supermarket Danfoss has installed all the lasted technologies and solutions to achieve one of the most energy efficient supermarkets possible.