Energy-efficient motor control

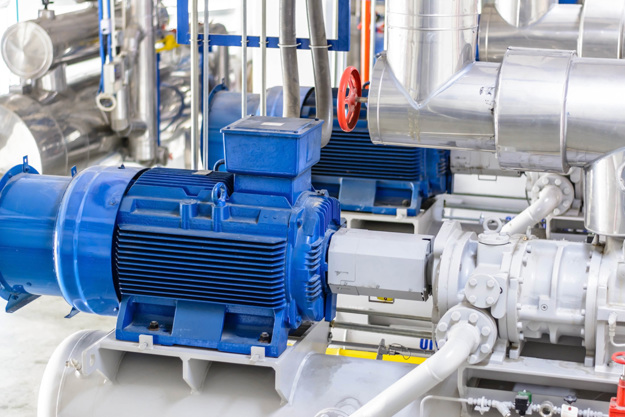

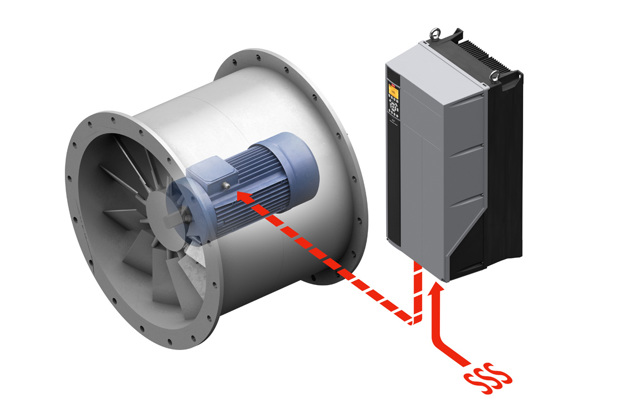

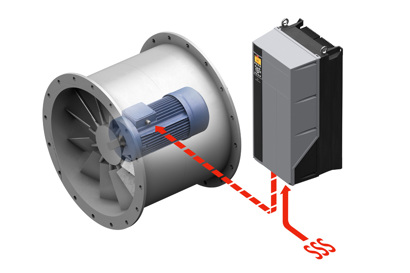

The VLT® AutomationDrive FC 360 is a compact, space-saving, general-purpose AC drive available in 5 frame sizes. Designed with ease-of-use, reliability and flexibility in mind, the basic, yet comprehensive features provide precise and energy-efficient motor control for a wide range of industrial applications.

The VLT® AutomationDrive is designed to perform reliably in harsh environments. The coated PCB reduces dust, moisture and particle issues and the maximum operating temperature is 55C. Built-in features, such as PID controller, EMC filter, DC choke and brake chopper to 22 kW, save costs and installation space. IP 20 protection, a removable fan and an enhanced numerical display ensure fast setup and simpler maintenance.

Supply voltages and power range

- 3 x 380 – 480 V 0.37 – 75 kW

Features and benefits

Reliable operation in many environments due ambient temperature of 50°C, unique cooling concept and coated PCB

5–15% energy savings and reduced operational costs due to Automatic Energy Optimizer function

Fast cleaning and extended lifetime thanks to removable cooling fan

No need for external controller due to built-in PID controller

Fast and easy commissioning as a result of enhanced numerical display and clear application selection guidance

Documents

| Type | Name | Language | Valid for | Updated | Download | File type |

|---|---|---|---|---|---|---|

| Brochure | 9 Tips towards energy efficiency | English | Multiple | 09 Jan, 2023 | 79.2 MB | |

| Brochure | DrivePro® Services Overview | English | Multiple | 03 Feb, 2025 | 26.8 MB | |

| Case story | Kolomela Mine SA | English | Multiple | 16 Mar, 2023 | 4.2 MB | |

| Case story | Markus Kaffee | English | Multiple | 19 Jul, 2023 | 1.0 MB | |

| Fact sheet | VLT AutomationDrive FC 360 | English | Multiple | 15 Jul, 2024 | 7.8 MB | |

| Operating guide | VLT AutomationDrive FC 360 (0.37–90 kW) | English | Multiple | 06 May, 2024 | 3.8 MB | |

| Brochure | VLT AutomationDrive FC 360 Selection Guide | English | Multiple | 24 Mar, 2025 | 15.3 MB | |

| Operating guide | VLT AutomationDrive FC360 (90–315 kW) | English | Multiple | 20 May, 2024 | 6.1 MB | |

| Design guide | VLT Brake Resistor MCE 101 | English | Multiple | 13 Sep, 2016 | 6.7 MB | |

| Design guide | VLT® AutomationDrive FC 360 (0.37–90 kW) | English | Multiple | 08 Aug, 2024 | 3.9 MB | |

| Design guide | VLT® AutomationDrive FC 360 90–315 kW | English | Multiple | 18 Jan, 2024 | 5.6 MB | |

| Design guide | VLT® Brake Resistor MCE 101 | English | Multiple | 08 May, 2014 | 8.5 MB | |

| Brochure | VLT® Functional Safety | English | Multiple | 12 Nov, 2021 | 2.7 MB |

3D models and drawings

| Type | Name | Language | Updated | Download | File type |

|---|---|---|---|---|---|

| Eplan drawing | 132B0282_Eplan | 26 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | 132B0283_Eplan | 26 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | FC-360H11KT4E20H2BXCDXXSXXXXA0BX | 25 Jan, 2025 | 1.6 MB | .zip | |

| Eplan drawing | FC-360H11KT4E20H2BXCDXXSXXXXALBX | 26 Jan, 2025 | 1.6 MB | .zip | |

| Eplan drawing | FC-360H11KT4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.6 MB | .zip | |

| Eplan drawing | FC-360H15KT4E20H2BXCDXXSXXXXA0BX | 26 Jan, 2025 | 1.6 MB | .zip | |

| Eplan drawing | FC-360H15KT4E20H2BXCDXXSXXXXALBX | 25 Jan, 2025 | 1.6 MB | .zip | |

| Eplan drawing | FC-360H15KT4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.6 MB | .zip | |

| Eplan drawing | FC-360H18KT4E20H2BXCDXXSXXXXA0BX | 26 Jan, 2025 | 1.7 MB | .zip | |

| Eplan drawing | FC-360H18KT4E20H2BXCDXXSXXXXALBX | 26 Jan, 2025 | 1.7 MB | .zip | |

| Eplan drawing | FC-360H18KT4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.7 MB | .zip | |

| Eplan drawing | FC-360H1K1T4E20H2BXCDXXSXXXXA0BX | 27 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H1K1T4E20H2BXCDXXSXXXXALBX | 25 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H1K1T4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H1K5T4E20H2BXCDXXSXXXXA0BX | 27 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H1K5T4E20H2BXCDXXSXXXXALBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H1K5T4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H22KT4E20H2BXCDXXSXXXXA0BX | 25 Jan, 2025 | 1.7 MB | .zip | |

| Eplan drawing | FC-360H22KT4E20H2BXCDXXSXXXXALBX | 25 Jan, 2025 | 1.7 MB | .zip | |

| Eplan drawing | FC-360H22KT4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.7 MB | .zip | |

| Eplan drawing | FC-360H2K2T4E20H2BXCDXXSXXXXA0BX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H2K2T4E20H2BXCDXXSXXXXALBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H2K2T4E20H2BXCDXXSXXXXAXBX | 25 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H30KT4E20H2XXCDXXSXXXXA0BX | 26 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-360H30KT4E20H2XXCDXXSXXXXALBX | 25 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-360H30KT4E20H2XXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-360H37KT4E20H2XXCDXXSXXXXA0BX | 25 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-360H37KT4E20H2XXCDXXSXXXXALBX | 26 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-360H37KT4E20H2XXCDXXSXXXXAXBX | 27 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-360H3K0T4E20H2BXCDXXSXXXXA0BX | 27 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H3K0T4E20H2BXCDXXSXXXXALBX | 25 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H3K0T4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H45KT4E20H2XXCDXXSXXXXA0BX | 26 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-360H45KT4E20H2XXCDXXSXXXXALBX | 25 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-360H45KT4E20H2XXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-360H4K0T4E20H2BXCDXXSXXXXA0BX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H4K0T4E20H2BXCDXXSXXXXALBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H4K0T4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H55KT4E20H2XXCDXXSXXXXA0BX | 26 Jan, 2025 | 742.6 KB | .zip | |

| Eplan drawing | FC-360H55KT4E20H2XXCDXXSXXXXALBX | 27 Jan, 2025 | 742.9 KB | .zip | |

| Eplan drawing | FC-360H55KT4E20H2XXCDXXSXXXXAXBX | 26 Jan, 2025 | 741.9 KB | .zip | |

| Eplan drawing | FC-360H5K5T4E20H2BXCDXXSXXXXA0BX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H5K5T4E20H2BXCDXXSXXXXALBX | 27 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H5K5T4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360H75KT4E20H2XXCDXXSXXXXA0BX | 26 Jan, 2025 | 742.7 KB | .zip | |

| Eplan drawing | FC-360H75KT4E20H2XXCDXXSXXXXALBX | 25 Jan, 2025 | 742.9 KB | .zip | |

| Eplan drawing | FC-360H75KT4E20H2XXCDXXSXXXXAXBX | 26 Jan, 2025 | 741.9 KB | .zip | |

| Eplan drawing | FC-360H7K5T4E20H2BXCDXXSXXXXA0BX | 25 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | FC-360H7K5T4E20H2BXCDXXSXXXXALBX | 27 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | FC-360H7K5T4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.4 MB | .zip | |

| Eplan drawing | FC-360HK37T4E20H2BXCDXXSXXXXA0BX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360HK37T4E20H2BXCDXXSXXXXALBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360HK37T4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360HK55T4E20H2BXCDXXSXXXXA0BX | 27 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360HK55T4E20H2BXCDXXSXXXXALBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360HK55T4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360HK75T4E20H2BXCDXXSXXXXA0BX | 25 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360HK75T4E20H2BXCDXXSXXXXALBX | 25 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360HK75T4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.5 MB | .zip | |

| Eplan drawing | FC-360Q11KT4E20H2BXCDXXSXXXXAXBX | 25 Jan, 2025 | 1.6 MB | .zip | |

| Eplan drawing | FC-360Q15KT4E20H2BXCDXXSXXXXAXBX | 27 Jan, 2025 | 1.6 MB | .zip | |

| Eplan drawing | FC-360Q18KT4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.7 MB | .zip | |

| Eplan drawing | FC-360Q22KT4E20H2BXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.7 MB | .zip | |

| Eplan drawing | FC-360Q30KT4E20H2XXCDXXSXXXXAXBX | 26 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-360Q37KT4E20H2XXCDXXSXXXXAXBX | 27 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-360Q45KT4E20H2XXCDXXSXXXXAXBX | 27 Jan, 2025 | 1.3 MB | .zip | |

| Eplan drawing | FC-360Q55KT4E20H2XXCDXXSXXXXAXBX | 27 Jan, 2025 | 741.9 KB | .zip | |

| Eplan drawing | FC-360Q75KT4E20H2XXCDXXSXXXXAXBX | 26 Jan, 2025 | 741.9 KB | .zip | |

| Eplan drawing | FC-360Q75KT4E20H2XXCDXXSXXXXAXBX | 26 Jan, 2025 | 741.9 KB | .zip | |

| Dimensional drawing | MCAD FC 360 J1 IP20 | 26 Jan, 2025 | 221.4 KB | ||

| Dimensional drawing | MCAD FC 360 J1 IP20 | 26 Jan, 2025 | 3.4 MB | .dxf | |

| Dimensional drawing | MCAD FC 360 J1 IP20 | 26 Jan, 2025 | 50.7 MB | .stp | |

| Dimensional drawing | MCAD FC 360 J1 IP20 | 26 Jan, 2025 | 119.5 MB | .igs | |

| Dimensional drawing | MCAD FC 360 J2 IP20 | 27 Jan, 2025 | 54.2 MB | .stp | |

| Dimensional drawing | MCAD FC 360 J2 IP20 | 27 Jan, 2025 | 97.0 MB | .igs | |

| Dimensional drawing | MCAD FC 360 J2 IP20 | 26 Jan, 2025 | 5.3 MB | .dxf | |

| Dimensional drawing | MCAD FC 360 J2 IP20 | 26 Jan, 2025 | 676.6 KB | ||

| Dimensional drawing | MCAD FC 360 J3 IP20 | 26 Jan, 2025 | 938.3 KB | ||

| Dimensional drawing | MCAD FC 360 J3 IP20 | 27 Jan, 2025 | 62.5 MB | .stp | |

| Dimensional drawing | MCAD FC 360 J3 IP20 | 25 Jan, 2025 | 6.6 MB | .dxf | |

| Dimensional drawing | MCAD FC 360 J3 IP20 | 25 Jan, 2025 | 52.0 MB | .igs | |

| Dimensional drawing | MCAD FC 360 J4 IP20 | 25 Jan, 2025 | 71.3 MB | .stp | |

| Dimensional drawing | MCAD FC 360 J4 IP20 | 25 Jan, 2025 | 833.1 KB | ||

| Dimensional drawing | MCAD FC 360 J4 IP20 | 26 Jan, 2025 | 121.5 MB | .igs | |

| Dimensional drawing | MCAD FC 360 J4 IP20 | 26 Jan, 2025 | 5.5 MB | .dxf | |

| Dimensional drawing | MCAD FC 360 J5 IP20 | 25 Jan, 2025 | 760.6 KB | ||

| Dimensional drawing | MCAD FC 360 J5 IP20 | 26 Jan, 2025 | 5.3 MB | .dxf | |

| Dimensional drawing | MCAD FC 360 J5 IP20 | 27 Jan, 2025 | 82.3 MB | .stp | |

| Dimensional drawing | MCAD FC 360 J5 IP20 | 25 Jan, 2025 | 119.7 MB | .igs | |

| Dimensional drawing | MCAD FC 360 J6 IP20 | 27 Jan, 2025 | 6.8 MB | .dxf | |

| Dimensional drawing | MCAD FC 360 J6 IP20 | 26 Jan, 2025 | 58.2 MB | .stp | |

| Dimensional drawing | MCAD FC 360 J6 IP20 | 26 Jan, 2025 | 175.2 MB | .igs | |

| Dimensional drawing | MCAD FC 360 J6 IP20 | 26 Jan, 2025 | 1.3 MB | ||

| Dimensional drawing | MCAD FC 360 J7 IP20 | 26 Jan, 2025 | 643.5 KB | ||

| Dimensional drawing | MCAD FC 360 J7 IP20 | 25 Jan, 2025 | 42.7 MB | .stp | |

| Dimensional drawing | MCAD FC 360 J7 IP20 | 26 Jan, 2025 | 4.1 MB | .dxf | |

| Dimensional drawing | MCAD FC 360 J7 IP20 | 26 Jan, 2025 | 106.7 MB | .igs | |

| Dimensional drawing | MCAD FC 360 J8 IP20 | 27 Jan, 2025 | 30.7 MB | .stp | |

| Dimensional drawing | MCAD FC 360 J8 IP20 | 27 Jan, 2025 | 77.5 MB | .igs | |

| Dimensional drawing | MCAD FC 360 J8 IP20 | 25 Jan, 2025 | 5.2 MB | .dxf | |

| Dimensional drawing | MCAD FC 360 J8 IP20 | 25 Jan, 2025 | 350.8 KB | ||

| Dimensional drawing | MCAD FC 360 J9 IP20 | 25 Jan, 2025 | 460.6 KB | ||

| Dimensional drawing | MCAD FC 360 J9 IP20 | 25 Jan, 2025 | 7.1 MB | .dxf | |

| Dimensional drawing | MCAD FC 360 J9 IP20 | 26 Jan, 2025 | 41.0 MB | .stp | |

| Dimensional drawing | MCAD FC 360 J9 IP20 | 26 Jan, 2025 | 111.8 MB | .igs | |

| Dimensional drawing | MCAD VLT Blind Cover FC280 FC360 | 25 Jan, 2025 | 489.1 KB | ||

| Dimensional drawing | MCAD VLT Blind Cover FC280 FC360 | 25 Jan, 2025 | 672.8 KB | .stp | |

| Dimensional drawing | MCAD VLT Blind Cover FC280 FC360 | 30 Jan, 2025 | 1.3 MB | .dxf | |

| Dimensional drawing | MCAD VLT Control Panel LCP 21 | 26 Jan, 2025 | 686.1 KB | ||

| Dimensional drawing | MCAD VLT Control Panel LCP 21 | 26 Jan, 2025 | 16.0 MB | .stp | |

| Dimensional drawing | MCAD VLT Control Panel LCP 21 | 26 Jan, 2025 | 3.0 MB | .dxf | |

| Application drawing | VLT AutomationDrive FC 360 - Optical fiber rewind on dark background | 01 Dec, 2024 | 483.5 KB | .jpg | |

| Application drawing | VLT AutomationDrive FC 360 - Optical fiber rewind on white background | 01 Dec, 2024 | 675.4 KB | .jpg | |

| Circuit diagram | Wiring Schematic FC 360 | 25 Jan, 2025 | 59.9 KB |

Software

| Type | Software Characteristic | Name | Version | Language | Released | Status | Download | File type |

|---|---|---|---|---|---|---|---|---|

| System software | Library | VLT® AOI for Rockwell Studio 5000 | 1.00 | English | 17 Dec, 2019 | Released | 7.2 MB | .zip |

| System software | Library | VLT® Library for B&R Automation | 1.00 | English | 17 Dec, 2019 | Released | 7.1 MB | .zip |

| System software | Library | VLT® Library for TIA Portal | 1.12 | English | 17 Dec, 2019 | Released | 11.9 MB | .zip |

| System software | Library | VLT® Library for TwinCAT 3 | 1.12 | English | 17 Dec, 2019 | Released | 8.4 MB | .zip |

| System software | Library | VLT® Library for Unity Pro | 1.00 | English | 17 Dec, 2019 | Released | 9.7 MB | .zip |

| Software tools | VLT® Motion Control Tool MCT10 | 5.50 | English | 14 Jul, 2022 | Released | 944.1 MB | .zip | |

| Software tools | VLT® Motion Control Tool MCT31 | 2.0.4 | English | 17 Oct, 2017 | Released | 25.2 MB | .zip |

Related applications

-

if (isSmallPicture) {

Drives for compressors in food and beverage

Drives for compressors in food and beverageCompressor speed control provides constant pressure regulation as well as reducing your energy consumption, especially for part-load operation.

-

if (isSmallPicture) {

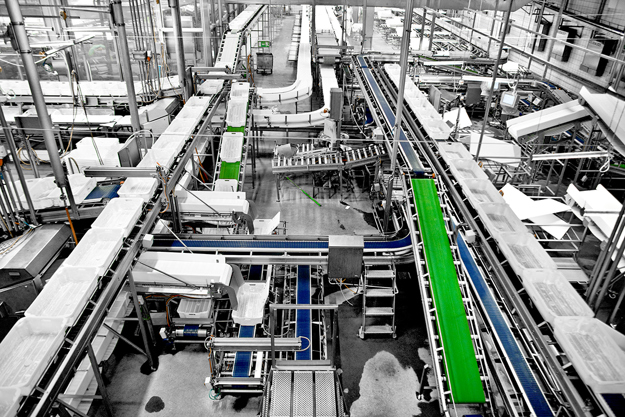

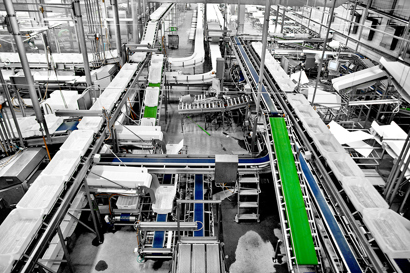

Drives for conveyors in food and beverage applications

Drives for conveyors in food and beverage applicationsEnsure maximum uptime and lowest possible cost of ownership with hygienic, variable-speed conveyor control. IPA-certified.

-

if (isSmallPicture) {

Drives for conveyors in mining

Drives for conveyors in miningFlexibility to control the speed of long conveyors can help optimize the complete system, reduce bottlenecks and extend motor lifetime.

-

if (isSmallPicture) {

Drives for fans in food and beverage applications

Drives for fans in food and beverage applicationsVariable speed fan control reduces costs by trimming energy consumption, and improves comfort levels by avoiding noise-generating frequencies.

-

if (isSmallPicture) {

Drives for industrial crane and hoist movement

Drives for industrial crane and hoist movementTo optimize crane performance, Danfoss offers flexible control strategies combined with energy efficiency, operating within stringent safety requirements.

-

if (isSmallPicture) {

Drives for marine fans and ventilation

Drives for marine fans and ventilationVariable frequency fan control saves energy and reduces noise in technical rooms and refrigeration systems throughout your vessel.

Case studies

-

if (isSmallPicture) {

Seawater cools Copenhagen city, cutting emissions by 70%

Seawater cools Copenhagen city, cutting emissions by 70%DENMARK: Two district cooling centrals in Copenhagen use seawater from Copenhagen Harbor for their cooling systems. For seven years, VLT® drives controlling pumps and compressors have proven their worth, ensuring high efficiency and impressive security of supply.

-

if (isSmallPicture) {

World leader in biogas reduces CO2 emissions by 50,000 t annually

World leader in biogas reduces CO2 emissions by 50,000 t annuallyBy generating power and heat from biogas instead of fossil fuels, MEC-BioGas reduces its CO2 footprint by 50000 tpa. Danfoss VLT® drives ensure optimal uptime in the 24/7 operations.

-

if (isSmallPicture) {

Shore power supply is a cost-effective solution for Maersk Supply Service’s parked vessels

Shore power supply is a cost-effective solution for Maersk Supply Service’s parked vesselsThanks to shore power supply during parking, Maersk Supply Service can keep diesel exhaust pollution, noise nuisance and maintenance costs to a minimum.

-

if (isSmallPicture) {

Back-channel cooling is a simple and efficient solution for the Sagrex Lemay quarry

Back-channel cooling is a simple and efficient solution for the Sagrex Lemay quarryA 35-year-old limestone crusher is no longer vulnerable to unplanned shutdowns, thanks to retrofit of a VLT® AutomationDrive FC 302 with back-channel cooling.

-

if (isSmallPicture) {

Bottling is more competitive when it is sensorless

Bottling is more competitive when it is sensorlessTo achieve higher productivity and energy efficiency on two new bottling lines, Tavina chose the Danfoss VLT® FlexConcept drive system.

-

if (isSmallPicture) {

Danish Crown super slaughterhouse saves 30 tEUR annually on motor replacement

Danish Crown super slaughterhouse saves 30 tEUR annually on motor replacementThe 1,000 VLT® drives installed throughout the plant control everything from simple conveyor belts to more advanced applications.

Contact us

For further information or to get a quote for this drive please contact us